1. Introduction to Bellow Compensator Expansion Joints

In the complicated world of piping systems, structural integrity and operational efficiency are considered key. Temperature, pressure, and mechanical movements cause considerable stress that could result in possible failures and costlier downtime. It is at this point that the bellow compensator expansion joint comes into play as a crucial element.

These special design pipe joints are engineered to absorb and manage the various stresses that piping systems encounter, ensuring smooth and safe operation across numerous industries. The bellow compensator expansion joint is not just a simple connector but an advanced solution that protects pipelines from the damaging effects of thermal expansion, vibration, and other mechanical forces.

2. Key Advantages of Bellow Compensator Expansion Joints

The bellow compensator expansion joint has a lot of advantages, making the element of a modern piping system indispensable. Advantages range from operational safety and cost-effectiveness, consolidating their status as one of the preferred solutions. Some of the key advantages of the expansion bellows compensators are given below:

2.1. Accommodation of Thermal Expansion

The main function of a bellow compensator expansion joint, among others, is to absorb thermal expansion or contraction. Temperature changes make piping expand or shrink, and sometimes the stress that pipes undergo as a result may be quite extensive. The bellows of an expansion joint would compress and extend with these movements so that such stress does not build up inside the piping, causing possible rupture. This therefore means that these kinds of adaptation capabilities assure a long, fatigue-free life in the entire infrastructure of piping.

2.2 Dampening of Vibration and Pressure Surge

The pressure surges and vibrations arise very frequently in Industrial applications. The mechanical disturbances create stress and result in damage to the pipelines and equipment and structures in the neighborhood. A bellow compensator expansion joint acts like a shock absorber. It thus helps to damp the vibrations and pressure surges so that forces will not harm delicate equipment like pumps and turbines in the smooth working of the system. Besides contributing to noise pollution, this considerably comforts the environment in which staff operate and protects them from more hazardous conditions.

2.3. De-stressing Pipe Systems

In a piping system lacking bellow compensator expansion joints, stress occurring due to thermal expansion, turbulence, and other pressure surges would build around joints and more susceptible areas, thus leading to bends, splits, and drips, meaning more expensive processes of repair. The bellow compensator’s expansion joint allows for these movements and forces to increase very minimal stress in the whole piping system. A reduction in the level of stress increases the life of the piping system, reduces maintenance, and cuts operating costs.

2.4. Versatility in Application

The bellow compensator expansion joint is not designed for any specific type of application. In fact, they are quite versatile and can be applied to a wide range of industries and systems-from high-temperature fluid handling in power plants to complex piping arrangements in chemical plants. One of the main advantages of the bellow compensator expansion joint is its versatility. Their ability to accommodate axial, lateral, and angular movements makes them suitable for various piping configurations.

2.5. Space Efficiency

The bellow compensator expansion joint is relatively space-effective when compared to the traditional expansion loops and bends. The advantage is more critical in locations where space limitation is experienced. Since the joints are compact, it reduces the amount of space utilized by piping systems, without affecting the performance of piping systems. This advantage is very essential for an industrially densely populated plant, which seeks to minimize space usage.

2.6. Cost-Effectiveness

Though the bellow compensator expansion joint can be a little bit expensive during its initial investment, this service proves quite economical. The joints, which help decrease the possibilities of leakages or failure, eventually minimize loss and resultant expensive repair emanating from downtimes. It will help in less scope for wide extensional supports with more accessory component needs that save a reasonable budget again. This will add to the overall cost-effectiveness of the system in the long run with less frequent maintenance and longer system life. The value of the bellow compensator expansion joint is more than its purchase price alone.

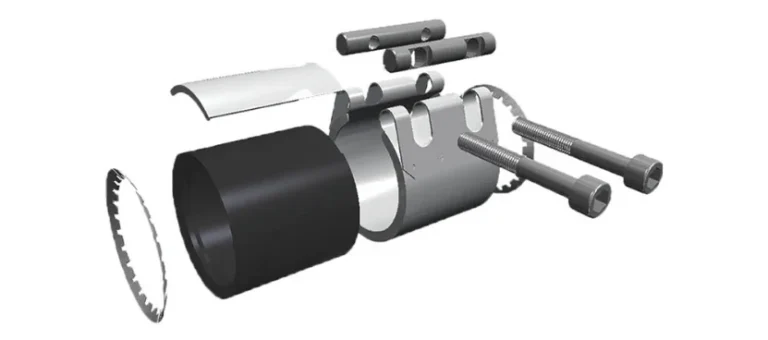

3. Types of Bellow Compensator Expansion Joints

There are several configurations of bellow compensator expansion joints for specific needs and requirements. Each is designed to absorb different types of movements and stress:

Axial Expansion Bellows:

Axial Expansion Bellows are designed to handle the linear motion along the axis of the pipe. They are ideal for piping systems with direct runs where expansion and contraction are a big concern.

Lateral Expansion Bellows:

Lateral Expansion Bellows are designed to handle side-to-side motion that reduces stress at joints and prevents misalignment.

Angular Expansion Bellows:

Angular Expansion Bellows are meant to absorb angular deflection and are useful in systems where the pipe joints are at different angles.

Universal Expansion Bellows

The Universal Expansion Bellows incorporate both axial and lateral bellows. They are suitable for systems that experience all types of movements. They can bear axial movement, lateral displacement, and angular rotation. They are thus applied in complex piping systems.

4. Materials Used in Bellow Compensator Expansion Joints

Material- The material that a bellow compensator expansion joint is made from is quite critical to both performance and service life. They are usually manufactured from high-class materials capable of bearing extreme temperatures, pressures, and corrosive surroundings, including:

Stainless Steel: This is one of the most commonly used metals because of strength, resistance to corrosion, and high-temperature-bearing ability. There are different types of stainless steel alloys in use depending on the specific requirements of the application.

High-Performance Alloys: In applications where the temperature is extremely high or when there are corrosive chemicals, Inconel, Monel, and Titanium are preferred. These materials provide excellent resistance under extreme conditions.

Lined Bellows: Where highly corrosive media must be handled, the bellow can be lined with such materials as PTFE that provides the required chemical resistance yet utilizes the strength of a metal bellow.

4. Applications of Bellow Compensator Expansion Joints

Bellow compensator expansion joints are used in the following applications in various industries:

Power Plants: Relieve thermal expansion and vibration in piping systems carrying steam and other high-temperature fluids.

Chemical and Petrochemical Industries: These serve to absorb the movement and turbulence in pipes transporting chemicals among other dangerous liquids.

HVAC Systems: Expansion joints bellow compensators provide for thermal expansion and contraction occurring in systems involving heating, ventilation, and air conditioning.

Water Treatment Plants: They are utilized in water treatment and waste treatment plants where there is a necessity to deal with thermal movements and vibrations in piping systems.

Aerospace and Medical Industry: In aerospace, they provide resilience and flexibility in exhaust and fuel lines. In medical appliances such as ventilators, they minutely regulate motion.

6. Conflex Joints: A Leader in Bellow Compensator Expansion Joints

Conflex Joints is one of the largest manufacturers of pipeline connection and repair products, boasting over 15 years of existence in the industry. Situated in Yingkou, Liaoning Province, China, Conflex Joints is committed to solving customer problems with a broad series of high-quality products. Equipped with a professional R&D team, it enjoys a good reputation in the international pipeline field.

Conflex Joints offers a wide range of pipeline joints including flange adaptors, couplings, dismantling joints, saddle clamps, repair clamps, flexible connections, accessories, and valves. Their focus on customer demand, continuous improvement in products, and strict quality control ensures that the products produced will meet the highest international standards.

Conflex Joints cooperates with SGS, BV, and other international third-party testing agencies in ensuring quality on exported products. A vision to be among the world pipeline connection service companies, Conflex Joints addresses the needs related to reliability in innovation for almost all industries situated in Europe, America, Latin America, Africa, Asia, and Australia. Among many salient features and advantages, Bellow Compensator Expansion Joints by Conflex Joints accommodate thermal growth, damp out vibration, relieve piping system stresses, and many other reasons highly preferable for several applications.