Piping networks, often an afterthought, “set-it-and-forget-it” feature of building construction, can instantly turn into a headache and become bad with cracks, leaks, or other surprise failures. Pipe repair clamps, however, offer a cheap and easy method of stopping leaks without the cost of replacements.But with so many models available, how do you choose the right pipe repair clamp for your application?

Why Are Pipe Repair Clamps Important?

Pipe repair clamps are a must-have tool for do-it-yourself individuals and professional plumbers alike. They offer a simple and effective way of fixing temporary or long-term pipe leaks, ranging from a pinhole to an open gap. Saving time and money and avoiding further damage to your property or infrastructure is achieved with the right clamp.

Key Points to Consider When Choosing a Pipe Repair Clamp

Selecting the right pipe repair clamp can look straightforward at first sight, but there are some essential things to consider. Doing it the wrong way will have weak repairs or, worse, make the problem even greater. Keep in mind the following:

1. Pipe Material and Diameter

Different materials require different clamps. Whatever material you are fixing — PVC, copper, steel, or cast iron — a clamp to fix what you are fixing must be employed. It is a robust, long-lasting fix. Taking the right measurement of the diameter of the pipe also must be correct. A misfitting clamp will leak or damage more.

2. Type of Leak or Damage

The extent of the pipe damage—puncture, crack, or breakage—will also determine what kind of clamp you would use. For pinhole-sized leaks, very frequently a plain patch clamp would be used to plug it. A multi-sectional clamp or wraparound clamp could be used in the event of poor cracks or disastrous damage so that one would have proper coverage and support. You should always verify the leak size while choosing a clamp so that it fits well.

3. Pressure and Temperature Ratings

Maximum temperature and pressure ratings are given for every pipe. Your clamp must be at least as much or greater than these in order to seal securely. A low-pressure or temperature capacity clamp can explode and cause increased leakage and potential damage. Consult the specifications to ensure that your clamp is appropriate for your system operating conditions.

4. Corrosion Resistance

If your system is to be subjected to severe environmental conditions—such as saltwater, chemicals, or very high/very low temperatures—corrosion resistance becomes a primary concern. Employ repair clamps made of corrosion-resistant material such as stainless steel or copper. Thus, the clamp will be able to withstand the environment and seal for an extended period of time.

5. Ease of Installation

For DIY or repair, ease of installation is also high on the agenda. There are clamps requiring professional-grade equipment, but some can be easily installed with basic equipment, which leaves you with less time and effort to attain. If you require a clamp that can be easily applied quickly without much inconvenience, choose one that does not require professional-grade equipment.

6. Price

Budget is never an issue, but when it comes to pipe repair, you do not compromise because it may end up costing you in the future. Cheap clamps might be inexpensive initially but lead to ongoing leakage and other issues. You are better off spending money on a good clamp that will ensure long-term durability, especially in the event of long-term repair or one that is critical.

Common Pipe Repair Clamp Types

There are numerous designs of pipe repair clamps, and each one is suited to certain types of damage and application. The most common ones include:

C-Clamps

C-clamps are general-purpose tools consisting of a C-shaped body and threaded screw, conventionally used for clamping pipes to be welded or cut. They are not intended for repairing leaks, however, but temporary repairs in particular situations.

Bar Clamps (F-Clamps)

They are a flat bar, sliding jaw, and screw that can be adjusted and are most effectively used for holding pipes together to assemble or glue them. Their large range of clamping is convenient but they are better suited more often for installation than leak repair.

Spring Clamps

Spring clamps use a spring action to provide quick, light-duty clamping. These are best for test repairs or small repairs where pressure is low.

Chain Clamps

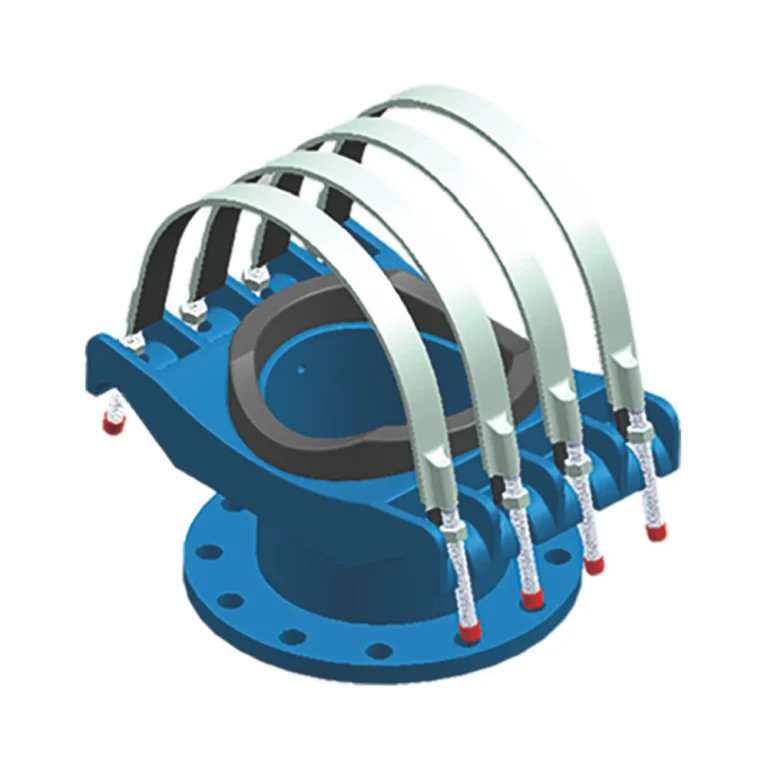

Chain clamps are employed to wrap around irregularly shaped or large pipes, distributing pressure in a uniform manner. They are convenient in usage in operations like welding, where the pipe can rotate freely when being welded.

Quick-Release Clamps

These clamps are meant to be used fast and with one hand and are handy for multiple uses or if time is a factor. They’re particularly handy when speed is a factor but not best for heavy-duty or extended repairs.

Repair Clamps

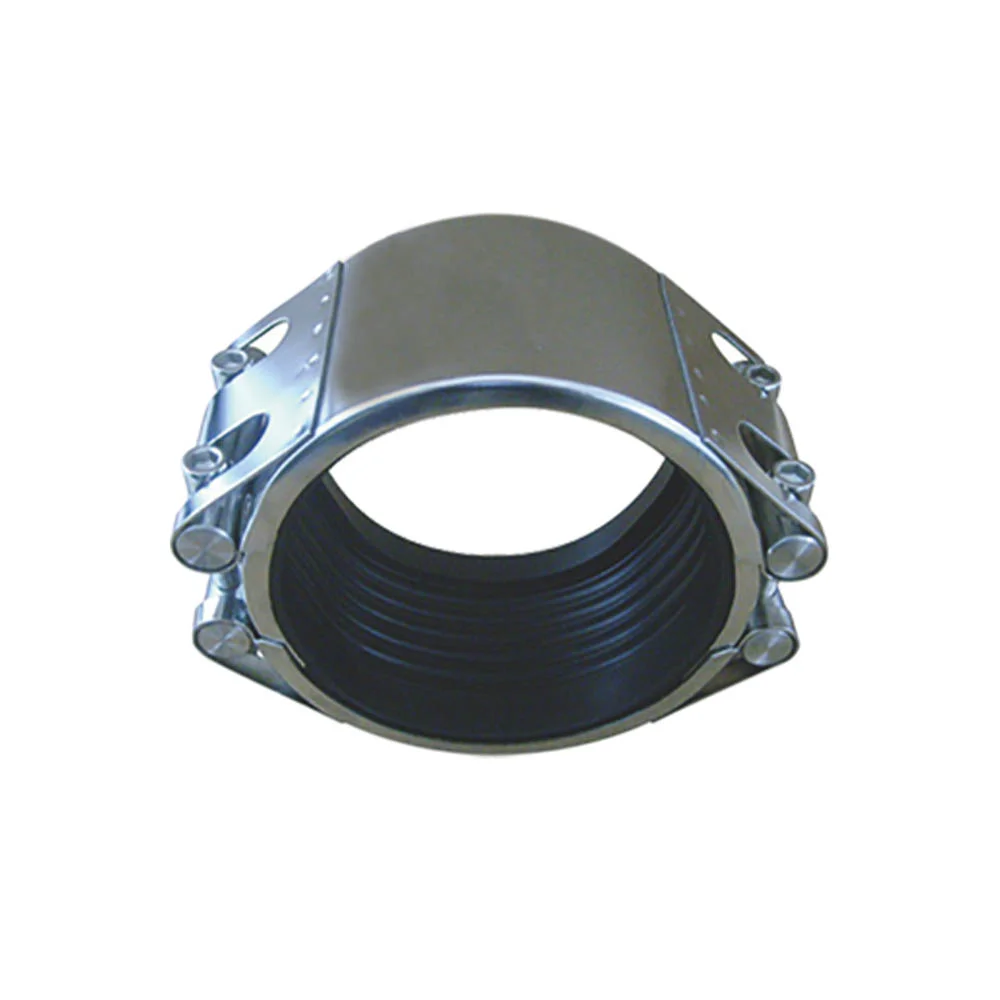

Repair clamps are the most prevalent form of pipe leakages repair. Repair clamps are a metal band encircling the leaking portion of the pipe that is sealed and tightened in the manner of tightening an inner rubber gasket. Repair clamps are of various types, i.e., split pipe clamps, saddle clamps, and compression clamps.

Split Pipe Clamps

These are installation-free-pipe clamps and are suitable for retrofitting or repairing pre-installed pipe leaks in the limited spaces. They are applied where access to the ends of the pipes is limited.

Saddle Clamps

Saddle clamps are employed to fix leaks in copper tubing, especially inaccessible ones such as behind the wall or ceiling. They are a metal plate that is slipped over the leak and bolted or screwed into position.

Materials Used in Pipe Repair Clamps

The type of material employed in the clamp is what makes it efficient in working and long-lasting. The most commonly employed materials are:

Steel

Steel clamps are highly resistant and durable and hence most suitable for extensive usage. They rust and corrode if poorly maintained.

Cast Iron

Cast iron clamps are hard and stiff but prone to breaking with excessive stress.

Aluminum

Aluminum clamps are resistant to corrosion and light in weight, and therefore can be used in wet or outdoor environments. However, they can be weaker than steel or cast iron.

Plastic

Plastic clamps are cheap but cannot be as long-lasting as metal clamps. Plastic clamps are ideal for light use or for temporary working.

Conflex: Your Partner in Pipeline Solutions

For clients looking for high-quality pipe repair services, Conflex Joints is a renowned manufacturer as over 15 years now. Conflex produces a vast range of repair clamps for various pipe materials and types of pipe damage. With simple installation facilities and long duration performance, its products are the first choice of engineers as well as contractors worldwide.

Key Features of Conflex Repair Clamps

- Longevity: Constructed with high-quality material like stainless steel, Conflex clamps are corrosion-resistant and have a longer lifespan.

- Quick Installation:Simple installation within seconds without the use of any tool, Conflex clamps are ideal for temporary applications as well as permanent installations.

- Flexibility: Ideal for different applications like water, sewage, and gas pipes.

- Multi-Product Portfolio:Conflex offers various sizes and forms of repair clamps for accommodating various piping systems, from household pipes to industrial uses on a very large scale.

Major Products of Conflex:

- FCE Stainless Steel Repair Clamp: Ideal for rusty or old pipes, it is an economic product that can also be employed in potable water systems.

- FCH Stainless Steel Repair Clamp:Simple and uncomplicated to apply, the clamp is well suited to seal leaks in industrial pipeline systems.

Choosing the right pipe repair clamp is important to ensure the integrity and life of your piping system. Through the assessment of material, leak type, pressure rating, and corrosion resistance, you can identify the best clamp for your specific application. For quality, dependability, and fast installation, Conflex Joints offers reliable and efficient solutions that can be applied to various industries.