In pipe and plumbing systems, even the smallest of parts play the lead role in making the system leakage-free and efficient and avoiding costly delays. A saddle clamp is one such crucial part.

But you may be wondering about the question, How does proper installation of saddle clamps for pipes guarantee maximum performance? Let’s find out the details of saddle clamp installation and learn the secrets of a leak-free and long-lasting system.

What are Saddle Clamps and Why Should You Care If They Are Installed?

Saddle clamp is one of the types of pipe fittings that are employed in the joining of two pipes. Saddle clamps are very convenient fittings which can be employed to join pipes without cutting or welding the master pipe, so they are very convenient for numerous applications.

The saddle clamps are typically made of hard material such as polypropylene (PP) and used both in the home and in the workplace for applications such as making branch lines and installing fixtures like faucets and water meters.

Since they are in charge of right seals with no leak, the significance of correct installation would be apparent. Off-center saddle clamp means leakage, low pressure, and ultimately, repair.

These reasons alone are why we do not recommend doing it yourself, we’re insisting on maximum pipeline performance.

Before You Begin: Did You Finish these Critical Pre-Steps?

Have You Chosen the Correct Saddle Clamp for the Job?

The first and perhaps most crucial step is selecting the appropriate size and style of saddle clamp for your specific application. Different types of pipes and connection requirements require different styles of clamps.

You might need a PP saddle clamp for plastic or a universal saddle clamp for multi-material uses like for DI, PE, PVC, and steel. Getting advice from a specialist or a trusted manufacturer like Conflex Joints ensures that you choose the right clamp for your needs.

Is the Pipe Properly Prepared for Installation?

Once you have obtained the correct clamp, the second most vital step is preparing the pipe. It involves the cleaning of the pipe and the area where the saddle clamp will be located. You should use a cleaning solution or a rag to clean off any grease, debris, or dirt.

To get the best results, some people recommend applying primer to make sure the saddle clamp adheres to the pipe well.

Having a clean surface will allow for a proper seal. In the case of rough pipes, using the proper gasket lubricant will also yield a correct seal.

Step-by-Step: How Do You Install Various Types of Saddle Clamps Properly?

For Standard PP Saddle Clamps, Are You Following These Steps?

- Mount the Clamp: Remove the wrapping and position the PP saddle clamp on the pipe where you want to mount it.

- Secure the Clamp:Tighten the bolts or screws that come with the clamp to secure it firmly to the pipe. Use equal pressure all around the pipe to avoid leaks.

When You’re Tapping Using a Tapping Saddle, Do You Use These Extra Precautions?

- Clean the Pipe: Clean the pipe in the area where you will be applying the saddle.

- Assembly of the Saddle:Tapping saddles are typically two halves with a ring seal and bolts between them.

- Position and Bolt: Place the back of the saddle onto the pipe in the required position, so that the seal is where it should be. Secure bolts evenly.

- Create the Tap:If necessary, make a hole in the pipe by using a drill bit. Where possible, switch off the water supply.

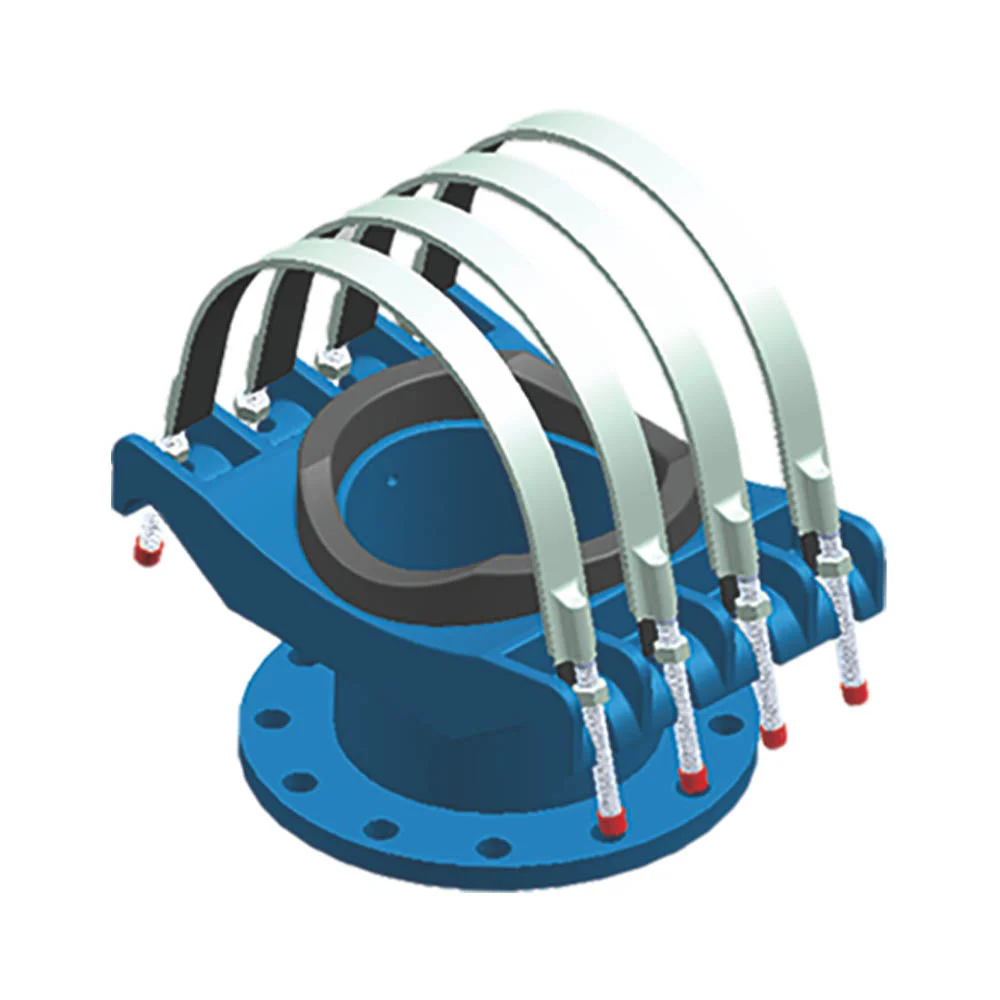

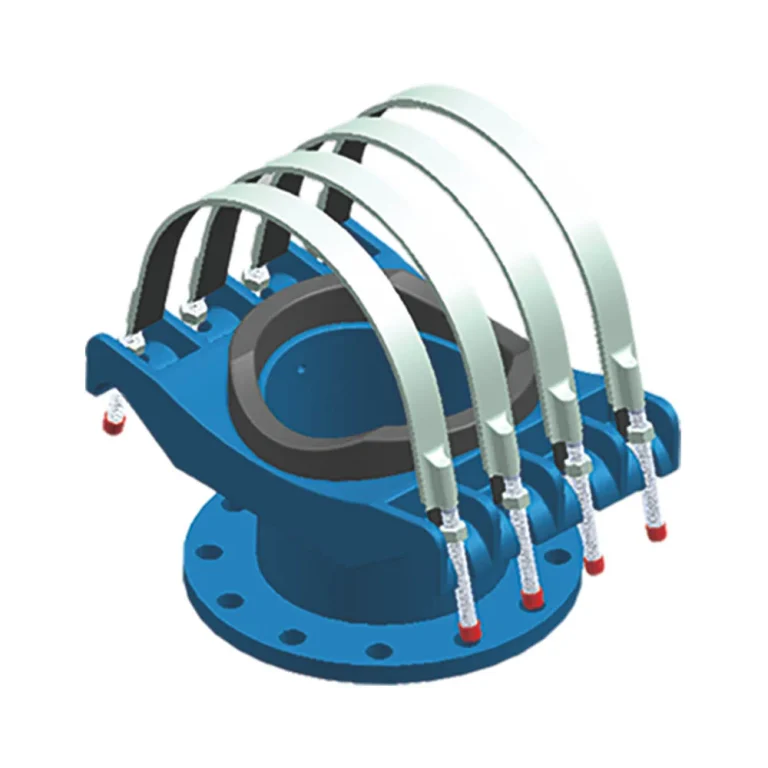

For Saddle Flange Tee Clamps, Are These Details Being Taken into Account?

- Positioning:Position the clamp over the pipe where you wish it.

- Bolting:Draw the two halves of the clamp together using the provided high-strength bolts and nuts. Ensure the rubber gasket is seated.

The All-Critical Final Step: Have You Checked for Leaks?

After you’ve installed the saddle clamp, there’s one final step that you need to perform: critical leak check. Turn on the water supply and carefully inspect around the area where the new saddle clamp has just been installed for leaks.

In case you do observe some leaks, turn off the water and double-check the installation steps of yours. Ensure that you have everything of yours in place and that you have properly tightened up the screws or the bolts.

What Are the Benefits You Can Reap from Properly Installed Saddle Clamps

Ease of Use

Saddle clamps are designed for easy and rapid connection of pipes without cutting or welding.

Reliable Performance

Installed correctly, they ensure a leak-free and safe connection.

Versatility

They can be used in a wide variety of applications for pipe connection and fitting installation.

Durability

With robust materials like polypropylene or ductile iron, they can withstand many conditions.

Cost-Effectiveness

They provide an inexpensive method of pipe connection and, when properly installed, avoid costly repairs through leaks.

Suitability for Potable Water

All saddle clamps, for example, from Conflex Joints, are WRAS approved and potable water suitable.

Conclusion: Why the Installation is a Non-Negotiable

Proper installation and maintenance are the backbone of an effective and secure plumbing system.

By selecting the right saddle clamp with care, properly preparing the pipe, doing the proper installation procedure, and exercising proper care in leak checking, you can unlock the ultimate performance of these vital fittings.

Be it constructing a new branch line or even putting in a water meter, knowing how to install saddle clamps correctly is a gigantic key to achieving peak performance and prevention of hassles in the future.

Always adhere to the manufacturer’s instructions for the specific saddle clamp you are using.