Application Description

1. There is 5-10mm telescopic adjustment between socket ends.

The pipe can be cut into different lengths, and pipe connection is changed from a socket pipe to a flange connecting pipe.

Install easily and quickly. Using only one torque wrench to tighten high strength bolted connection.

2. Wide range of different pipe OD with +/- 6° deviation.

It can be used in the large bending radius pipeline and allowable for the normal movement of the pipe such as ground subsidence.

3. The simplicity and versatility of this product make them suitable for many applications including pumping stations, water purification plants, sewage treatment plants, plat rooms, instrument rooms, power generation equipment, gas stations and all pipelines.

4. Product design and manufacture according to BS, EN, ISO, 9001:2008 system and surface anti-corrosion material through the most stringent WRAS certification, so it can be used for drinking water.

5. We provide EPDM, SBR, NBR rubber pad and carbon steel/stainless steel bolts for long term rust protection.

Installation Manual

|

|

|

|

1. Check if the components of the product have been lost in transport and check for product surface.

2. Clean the surface of the pipe spigot, cleaning length is the same as half of joint length.

3. Check the surface of sealing ring and make sure that the surface is free of cracks neither deformations which will interfere the effect of rubber ring.

4. Draw an equal reference point on spigot end of pipe, which is half the length of the coupling joint, and calculate from the spigot end.

5. Place a gland flange at each pipe reference point.

6.Apply the lubricant to the gland flange and pipe surface.

7. Put the gland flange and rubber on the pipe, the ramp is inclined toward the pipe end.

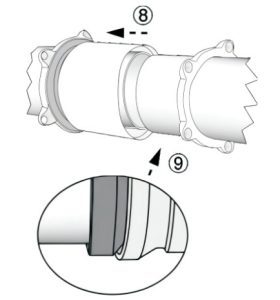

8. Insert the sleeve onto the pipe.

9. The two socket pipes should be parallel, axial alignment. When connecting, there is a gap of 5mm-10mm between the two socket pipes.

10. Move the sleeve to ensure that the center of the sleeve is same with the spigot and socket pipe center, and the distance between the two pipes is equal. The rubber ring is moved to the bell mouth of the sleeve.”

11. Move two end gland flanges to the position of rubber and meet the bolt holes of gland flange.

12. Insert the bolt into the gland bore and tighten the bolt. The bolt shall be tightened alternately. The nut shall be tightened according to the demension of the bolt and the torque.After piping is pressurized, check if leakage caused by improper installation and settle it.

Common installation problems

1.The bolt is not tightened to the proper torque.

2.Rock or debris between pipe and gasket.

3.There is dirt on the bolt or nut.

4.The distance between the socket tubes is not placed as required.

5.The two socket tubes are not parallel or on the same axis.