Application Description

1. There is 50mm telescopic adjustment between double flange. It can adjust the connection length by means of adjusting the connecting bolts. Install easily and quickly. Using only one torque wrench to tighten high strength bolted connection.

2. This product can be quickly dismantled and very easy to serve valves pumps and instruments, it reduce the mantaince time for design changes in the future and reduce the downtime of pipeline. It is suitable for install and remove isolation valve, control valve, check valve, pressure release valve, flow meter, pump, flange pipe etc.

3. The simplicity and versatility of this product make them suitable for many applications including pumping stations, water purification plants, sewage treatment plants, plat rooms, instrument rooms, power generation equipment, gas stations and all pipelines.

4. Product design and manufacture according to BS, EN, ISO9001:2008 system and surface anti-corrosion material through the most stringent WRAS certification, so it can be used for drinking water.

5. We provide EPDM, SBR, NBR rubber pad and carbon steel/stainless steel bolts for long term rust protection.

Because this product can be connected to different pipe diameter pipeline, it can reduce your investment in the inventory.

Installation Manual

1. Check the package and appearance of the product to ensure that it has not been damaged during the transport and that no parts have been lost.

2. Check the flange to which dismantling joint fits. Make sure it matches the bore of the product flange. Nominal pressure must be consistent.

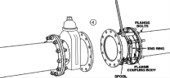

3. Remove the pull rod bolts from dismantling joint, loosen the nut, and take the pull rod bolts so that the pipe moves freely in the body of flange connection.

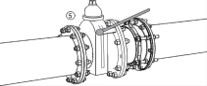

4. Move dismantling joint between the flanges to be assembled. There is a O ring gasket between the flange and the flange for sealing. Use flange bolts to secure the flange end of dismantling joint fix the flange end which need attach. Screw the bolt tightly.

5. Connect the flange spigot to the opposite mating flange. Flange type O gaskets are added between the flange faces and bolted together with flange bolts.

6. After bolts connect flange, self sealing of dismantling joint put into the program. At first in the middle of rubber seals with lubricant to ensure that the intermediate flange and intermediate sealing ring slide to the location, and check the small self connection bolt gasket and nut.

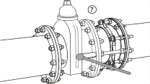

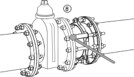

7. Insert the pull rod bolts. (Note: if no rod bolts, the product is not limited.) Each rod has 4 nuts at assembly. When the pull rod is inserted, the bolt is connected with the nut. The pull rod bolt lever must be through the flanges at both ends of dismantling joint. Make sure that the length of the connector is equal to meet the requirements of the flanges at both ends. The other nut tightening on the joint after tightening rod nut so as to complete the installation.

8. Evenly press the bolt on the press in the alternating direction of the screw until it reaches the recommended torque. Wait ten minutes, then torque.

Common installation problems

1.The bolt is not tightened to the proper torque.

2.Rock or debris between pipe and gasket.

3.There is dirt on the bolt or nut.

4.Short insertion distance of jack tube。

5.Incorrect pairing of Flange.