Application Description

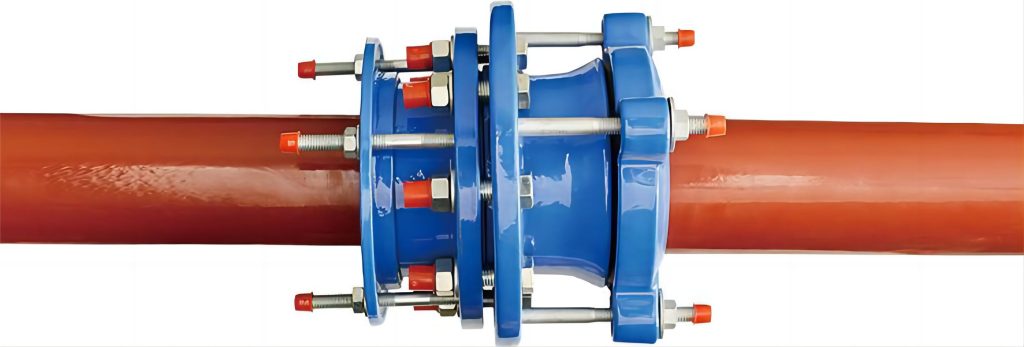

1. The pipe can be cut into different lengths, and pipe connection is changed from a socket pipe to a flange connecting pipe.

Install easily and quickly. Using only one torque wrench to tighten high strength bolted connection.

2. Wide range of different pipe OD with +/- 3° deviation.

It can be used in the large bending radius pipeline and allowable for the normal movement of the pipe such as ground subsidence.

3. The simplicity and versatility of this product make them suitable for many applications including pumping stations, water purification plants, sewage treatment plants, plat rooms, instrument rooms, power generation equipment, gas stations and all pipelines.

4. Product design and manufacture according to BS, EN, ISO9001:2008 system and surface anti-corrosion material through the most stringent WRAS certification, so it can be used for drinking water.

5. We provide EPDM, SBR, NBR rubber pad and carbon steel/stainless steel bolts for long term rust protection.

Installation Manuel

|

|

|

|

|

|

|

1. Check if the product package is damaged during transport and confirm if the product is missing accessories.

2. Clean the pipe surface of the spigot pipe, and the distance is greater than the length of flange adaptor.

3. Check the surface of the sealing ring, make sure the sealing ring has no dent, bump and knock, if any, it will affect the sealing performance of the sealing ring, and the sealing ring must be smooth and seamless.

4. Attach the flange adaptor of the flange to the pipe at one end of the pipe.

5. Apply a special lubricant to the sealing ring and place the sealing trap on the pipe (the end of the bevel of the sealing ring should be in accordance with the direction of the pipe socket)

6. Installation and connection of flange adaptor

I: Slide the flange connection to the end of the pipe and leave the 5mm-10mm clearance at the end of the flange.

Ⅱ: Connect the flange connection to the flange on the pipe and bolt it.

7. Check the gap between flange joint mouth and spigot pipe, the gap among the upper and lower left and right should be consistent.

8. Press the gland over the rubber and insert the bolt into the bolt hole.

9. Insert the bolt into the gland hole and tighten the bolt. The bolt shall be tightened alternately. The nut shall be tightened according to the dimension of the bolt and the torque. After piping is pressurized, check if leakage caused by improper installation.