Flange adaptors are crucial components in industrial pipeline systems, ensuring smooth and secure connections between pipes of different materials. Whether you’re working with HDPE, PVC, or metal pipes, flange adaptors play an integral role in minimizing leakage risks, improving system integrity, and simplifying installation processes. If you’re a business owner or an engineer, understanding the proper installation of flange adaptors can save you time, money, and maintenance headaches.

In this guide, we’ll walk you through a comprehensive, step-by-step checklist to ensure that yourflange adaptorinstallation is executed flawlessly. From preparation to troubleshooting common installation problems, we cover everything you need to know. Additionally, we will introduce Conflex Joints, a leading manufacturer of high-quality flange adaptors and pipeline connectors, known for their innovation and efficiency.

Introduction: Why Flange Adaptors Matter in Modern Pipelines

The flange adaptors basically connect the pipes made of different materials, for instance, HDPE/PVC and metal piping. The adaptors are also massively demanded in water supply, heating, gas, and chemical processing among several industries. They provide easy connections among different types of pipes, valves, and other equipment without complex welding or threading.

Choosing the right flange adaptor for your system ensures better flow, reduces maintenance costs, and extends the lifespan of your pipeline. However, proper installation is essential to avoid common issues like leakage, misalignment, and premature wear.

Below is the step-by-step installation checklist that will help you mount your flange adaptors like a pro-quickly, safely, with minimum downtime, and assurance that your pipeline system works just right.

Step 1: Pre-Installation Preparation – The Key to a Smooth Setup

Some groundwork needs to be done before the actual installation commences in terms of preparing materials and tools that will be required and a few checks. Proper preparation at this stage can save expensive mistakes later.

1.1. Check the Flange Adaptor Specifications

Ensure the flange adaptor selected is according to the pipe specifications. For example, Conflex Joints provides several varieties of flange adaptors, such as:

HDPE/PVC pipes Flange Adaptor (DN50-DN600)

PE pipes Flange Adjustable Adaptor (DN50-DN600)

PE/PVC pipes Flange Quick Adaptor (DN50-DN400)

These adaptors are for various sizes of pipes and different materials, and their selection is very important for a tight, leak-free joint.

1.2. Check Compatibility to Industry Standards

Ensure that the flange adaptorsare manufactured to relevant standards such as BS, EN, and ISO9001:2008 so that they are well adapted to high-pressure conditions, corrosion, and other hostile environments.

1.3. Prepare the Equipment

Prepare the appropriate tools to be used. These tools may include:

Torque wrench

Gasket material

Bolts and nuts

Lubricants for sealing

Pipe cutters or saws

Cleaning materials to clean the pipe surfaces from debris

Step 2: Inspect the Pipes and Flange Adaptors – Alignment is Key

A proper alignment is the secret behind a strong and efficient connection. Misaligned pipes promote leakage and excessive wear.

2.1. Clean the Pipe Surface

Clean the pipe and flange before the installation of the flange adaptor. For a perfect connection, no dirt, debris, or rust should remain. The wire brush or even cloth is used to wipe the surfaces.

2.2. Damaged Item Check

The visible damage such as cracks or rust in the pipe ends and flange adaptors are checked. The installation procedure can be continued only after the replacement of damaged materials.

2.3. Ensure Correct Pipe Alignment

Align the pipes to provide a proper fit of the flange adaptor. Since the design of the majority of flange adaptors enables them to easily align with other pipes, one may underestimate the possibility of poor alignment due to kinking or otherwise improper alignment, which could result in stress leading to leakage.

Step 3: Flange Adaptor Installation – Securing the Connection

With everything being prepared, you are set to install your flange adaptor.

3.1. Position the Flange Adaptor on the Pipe

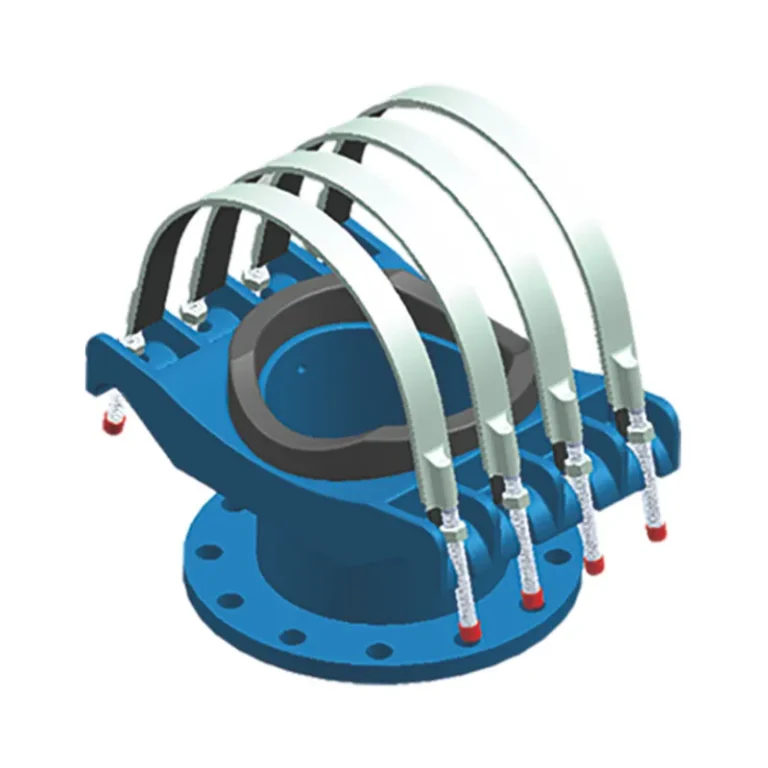

Place the flange adapter over the end of the pipe. Position the gasket or sealing material with the intention of making a tight, leak-proof seal. The method of sealing for the flange adaptors of Conflex Joints, socket type with a dovetail groove design, helps ensure that the pressure of the seal can resist pressures up to 2.5 MPa.

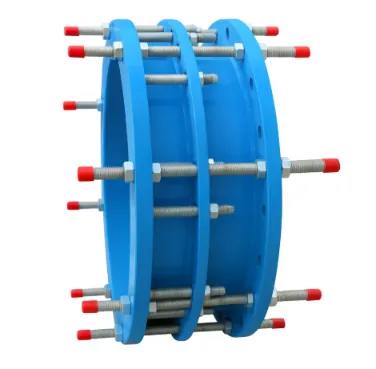

3.2. Tightening of Bolts Using a Torque Wrench

Begin by tightening the bolts by hand before using a torque wrench. Remember to tighten the bolts in a star pattern, from side to side. This keeps the pressure even and will not allow the flange adaptor to become misaligned.

3.3. Follow Manufacturer Torque Specifications

Always use the recommended torque values by the manufacturer. Over-tightening and under-tightening can lead to leaks or put additional stresses on the piping system. Conflex Joints flange adaptors are supplied with installation instructions, which will include the recommended torque value for each type of adaptor.

Step 4: Checks after Installation – Securing the Connection

Once the flange adaptor has been fitted and tightened, there are a few final checks that must be made.

4.1. Gasket and Seal Inspection

Inspect to see whether or not the gasket is appropriately compressed and seated to develop a tight seal. Very critical in preventing leakage. Conflex Joints provides the best quality rubber pads for sealing, including EPDM, SBR, and NBR. This gives them excellent resistance to high temperature and chemicals.

4.2. Pressure Test the System

Pressure test the connection for integrity. For high-pressure systems, such as those used in gas or water pipelines, this is more important. If leaks were found, readjust the bolts or check the gasket for damage.

4.3. Check for Proper Alignment Again

Recheck the alignments of the pipes and flange adaptors. Even minor misalignment can cause performance issues gradually.

Step 5: Troubleshooting Common Installation Issues

No installation can be perfect and free of bugs. Here are some potential problems with their solutions.

5.1. Leaking Connections

If the system starts to leak, this is where the bolts were not fully tightened or it has a breach in the gasket. It should either be placed properly or, if compromised, replaced by a new one.

5.2. Misalignment

If the pipes are out of alignment, re-inspect the pipe ends and flange adapter for any kinks or other abnormalities. Use a flexible flange adapter, such as those from Conflex Joints, which allow for some give to allow pipes of a size with a +/3° variance.

5.3. Rust or Corrosion Issues

Ensure the bolts and nuts are of corrosion-resistant material, such as stainless steel, when working in outdoors or otherwise unfriendly environments. Flange adaptors from Conflex Joints are designed with carbon steel and stainless steel bolts for resistance against rust and ensuring longevity.

Step 6: Why Choose Conflex Joints for Your Flange Adaptor Needs?

Conflex Joints supply a wide array of flange adaptors to meet the demands of industries reliant on secure, leak-free piping systems. With over 15 years of experience in the field, Conflex Joints has earned its reputation for high-quality production, with WRAS-certified products that are suitable for drinking water systems.

Key Benefits of Conflex Joints’ Flange Adaptors:

Flexibility: Adjustable designs, such as the Flange Adjustable Adaptor, can accommodate various pipe diameters and pipe misalignments, making them ideal for complex installations.

Easy Installation: The socket-type sealing and bolted connections are easy to install, reducing labor time and minimizing installation errors.

Durability: Their products are made with high-strength materials, including EPDM and NBR sealing rubber, designed for longevity and reliability in diverse environments.

WRAS Certified: All flange adapters are manufactured to meet the necessary requirements for drinking water safety so that your water pipeline systems can be considered safe and meet the required standards.

Conclusion: Ensure a Secure Pipeline with the Right Flange Adaptor Installation

By following this flange adaptor installation checklist, you can ensure that your pipeline systems are secure, efficient, and leak-free. Whether you’re dealing with water, gas, or chemical pipelines, the right flange adaptor will enhance performance and reduce maintenance costs.

Choose Conflex Joints for your flange adaptor needs and benefit from their years of expertise in the field of industrial pipeline connections. With their high-quality products and reliable customer service, you can be confident in the success of your installations.