When it comes to maintaining and managing industrial pipeline systems, ensuring flexibility and efficiency in installation and repairs is crucial. One of the most practical solutions for achieving this is the pipe dismantling joint. But a common question arises: Can pipe dismantling joints be used across different applications, or are they only suited for specific environments?

What is a Pipe Dismantling Joint?

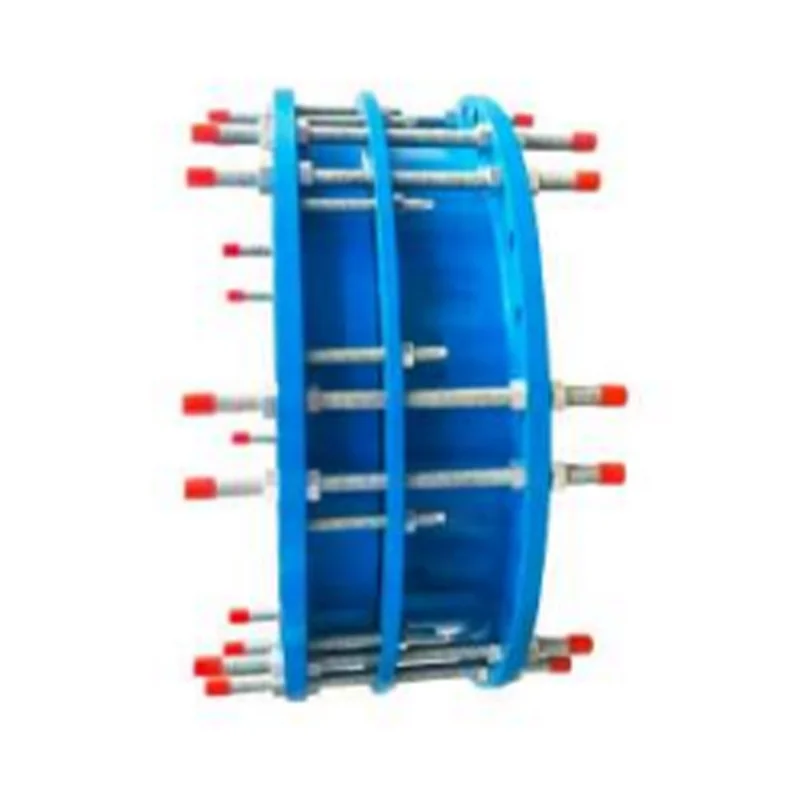

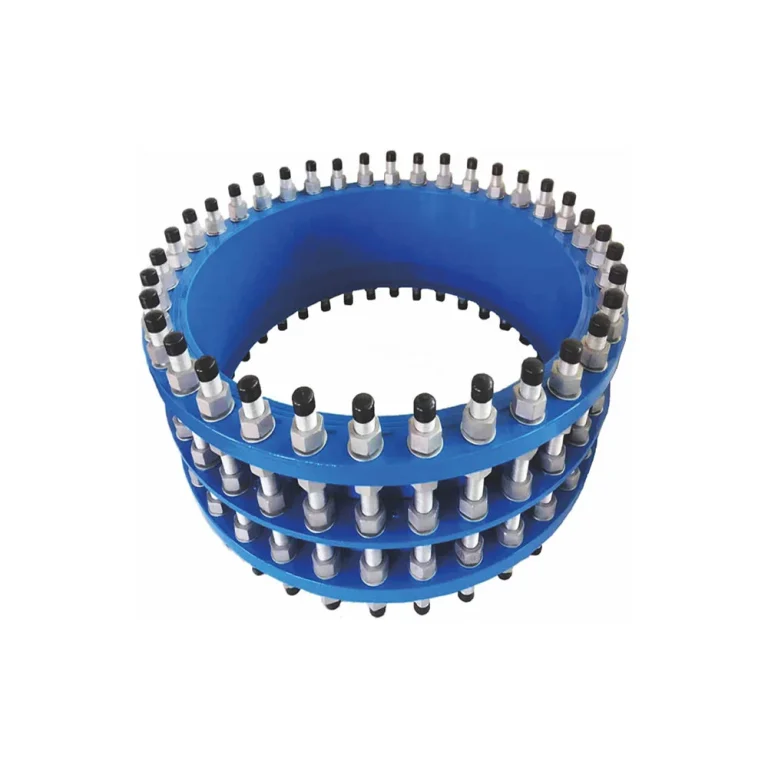

A pipe dismantling joint, also known as a flanged dismantling joint, is a mechanical component used to connect pipes, fittings, and valves that have flanges at both ends. These joints are specifically designed to facilitate the assembly and disassembly of piping systems, which makes maintenance, repairs, or modifications significantly easier and faster. They help isolate sections of the pipeline without disturbing the entire system, enabling engineers to efficiently access specific sections for servicing.

As industrial pipelines grow in complexity, the ability to quickly disconnect or reconfigure pipeline components becomes increasingly valuable.

Why is it Important for Different Applications?

Pipe dismantling joints are particularly beneficial for industrial systems that require regular maintenance or where future modifications are anticipated. In industries such as water treatment, oil and gas, sewage management, and chemical production, having easy access to pipeline sections can significantly reduce maintenance costs, system downtime, and labor expenses.Conflex Joints offers dismantling joints that are suitable for a wide range of applications, making them a versatile choice for companies operating across multiple industries.

Advantages of Pipe Dismantling Joints from Different Applications

Ease of Maintenance and Repair

One of the main advantages of using dismantling joints is the ease they bring in the management of pipelines. Every maintenance activity requires the isolation and access of a particular portion, and dismantling joints do just that without disrupting the process that may be ongoing on the rest of the pipeline. Thus, for a pumping station, routine maintenance works related to pumps or valves, etc. can be done in a very short time, just by disconnecting the relevant portion of the pipeline through the dismantling joints. Lesser downtime and more continuity is provided to the business.

The dismantling joints in steel that Conflex Joints offers, such as the Steel Dismantling Joint VSSJA C2F and Steel Dismantling Joint VSSJA CF, are perfect to work in such maintenance-heavy environments. The products are meant for use with a wide range of fluids such as seawater,freshwater, and crude oil, making them quite versatile across various industries.

Bridging Gaps in Complex Systems

These dismantling joints serve as bridges between different pipeline segments, especially in industries that contain a number of complicated networks, such as sewage treatment plants or oil refineries. They help to keep the pipes properly aligned, considering that multiple connections, branches, and bends may be involved. In its own respect, this facilitates smoother and more accurate installation. The dismantling joints can eliminate the poor alignment that results from changes in pipe diameter, changes in material of pipes, and installation tolerances.

Such a product, in order to bridge the gap between different segments of the pipeline, especially for the handling of high-pressure systems, is the Conflex Joints Steel Dismantling Joint VSSJA C2F. Advanced materials are used in its construction so that the system does not leak in high-pressure situations.

Ensuring Compliance and Durability

The dismantling joints used in various applications help companies to be compliant with local and international regulations. For example, in many regions, pipes used for potable water must strictly follow regulatory standards.Conflex Joints ensures that their products are WRAS certified, meaning their dismantling joints are safe for use in drinking water systems. This adds an extra layer of reliability for industries dealing in water distribution and treatment.

In the same direction, the dismantling joints either in ductile iron or steel, such as those by Conflex, are very durable, resistant to corrosion, and support high temperatures and pressure differences. For example, in the oil and gas industry, where pipelines are severely exposed to corrosive actions at high temperatures, the use of premium-class dismantling joints like VSSJA CF will definitely allow the system to operate longer without breaking up for repairs.

Cost-Effectiveness and Reduction in Maintenance Time

In most industries, cost cutbacks are usually put forward as the top priority. The dismantling pipe joints help in minimizing the overall cost of work. It assists the engineers in isolating certain pipeline sections in a very easy manner for repair and replacement. There is no need to dismantle large pipeline sections, which helps in saving considerable man-hours and material costs.

A practical example of this is in water treatment plants, where the pipelines require periodic inspections and maintenance. Installation of dismantling joints at appropriate places enables the plant to save much time and labor, which may arise during routine checks or sudden repairs.

Versatility Across Industries

A major feature of dismantling joints is their ability to be used across many industries. This makes them a favorite solution among engineers and businesses operating in different pipeline sectors.Conflex Joints manufactures dismantling joints that can be used in diverse environments, such as:

1.Water Treatment Plants: To manage fresh water distribution systems and sewage pipelines.

2.Pumping Stations: For maintenance and easy access to pump systems.

3.Chemical Processing Plants: To manage pipelines carrying various chemicals.

4.Oil and Gas Systems: To handle crude oil and refined oil pipelines with high-pressure requirements.

The Conflex Joints Steel Dismantling Joint VSSJA C2F is suitable for handling a range of materials, including crude oil,fuel oil, and lubricating oils, providing a high level of flexibility across industries dealing with different fluid types.

Regulatory Considerations: Ensuring Compliance with Standards

Pipe dismantling joints have different standards, depending on their application. For instance, in the water industry, those pipes that carry potable water must be within certain regulations such as the WRAS (Water Regulations Advisory Scheme) in the UK so that their materials will not foul the supply of water. Because of this very reason, the products dealt with by Conflex Joints are WRAS approved, hence safe to use for drinking water.

Moreover, international standards like ISO 9001 for Quality Management Systems and ISO 14001 for Environmental Management ensure that companies like Conflex Joints adhere to the best practices in the design, manufacture, and distribution of their various products. Companies operating in pipeline safety-regulated regions like North America and Europe mitigate compliance risks while ensuring pipeline system integrity through the deployment of certified dismantling joints.

Why Choose Conflex Joints for Your Dismantling Joint Needs?

Conflex Joints has emerged as a premier company manufacturing reliable pipeline connection and repair products. Over the years, these products have proved their worth to leading house builders while maintaining high international standards;Conflex has been able to gather valuable experience of over 15 years. The Steel Dismantling Joint VSSJA C2F and VSSJA CF are two prime examples of Conflex Joints to give better quality and valuable flexible products.

These dismantling joints guarantee ease of installation, reliable performance, and long service life, thus making them the ultimate choice for all companies in pursuit of effective pipeline management solutions. With WRAS certification and a wide ranging application base,Conflex Joints provide flexibility and dependability that enable the business to run smoothly across a wide array of industries.