Cast iron and ductile iron are prevalent materials in the automotive, construction, and engineering sectors. Though they share some similarities, there are a few differences that exist in the areas of mechanical properties, strength, and cost. It is wise to know the differences in order to be able to select the most appropriate material for your project.

This article provides you with a full cast iron vs. ductile iron review, its application, advantages, disadvantages, and price to allow you to make a well-informed decision.

Where Is Cast Iron and Ductile Iron Used?

Cast iron and ductile iron find application in every sector since they are durable, rust-free, and possess extremely low prices. This is where they are generally applied:

1. Construction Industry

- Structural components like columns use cast iron with compressive strength in consideration.

- Flexible parts and pipes use ductile iron in an effort to create room for temperature variation.

2. Motor Vehicle Auto Industry

- Cast iron is used on engine parts, which undergo pressure and heat resistance.

- Braking uses the application of using ductile iron, tensile and flexible in nature.

3. Petroleum and Gas Industry

Cast iron is used in shipbuilding.Corrosion-resistant and pressure-resistant plant and pipes utilize ductile iron.

4. Farm Equipment

- Tractor discs and irrigation discs employ ductile iron.

- Cast iron is employed by long-lasting farm equipment.

What Are the Advantages and Disadvantages of Cast Iron and Ductile Iron?

Both are good and bad.

1. Advantages and Disadvantages of Cast Iron

What Are the Advantages of Cast Iron?

- High Compressive Strength – Utilized for withstanding heavy loads.

- Good Corrosion Resistance – Used in applications exposed to water.

- Heat Resistant – Used in heat-sputtering application, i.e., engine manufacturing.

- Cost-Effective – Made up of material in abundance.

- Cast Easibility – Good good complex shape castability.

What Are the Weaknesses of Cast Iron?

- Brittle – Prone to crack upon impact.

- Thermal Sensitivity – Prone to thermal crack.

- Heavy – Weightiness contributes to overall weight.

- Low Hardness – Maybe not to exact machine machining.

- Rust-Prone – Susceptible to coatings for added corrosion protection.

2. Ductile Iron’s Strengths and Weaknesses

Advantages of Ductile Iron?

- High Flexibility – Stress resistant but will never crack.

- Impact Resistant – Offers resistance to vibration loading and shock.

- Corrosion Resistant – Offers good chemical resistance to aggressive atmospheres.

- Long Service Life – More wear and tear resistant.

- Good Machinability – Transportable to complex shape.

Weaknesses of Ductile Iron

- Increased Cost of Production – More costly due to special treatment.

- Heave – Weight becomes a concern in a particular application.

- Needs Anti-Corrosion Coating – Additional cost due to special treatment.

- Heat Sensitive – Diluted by structure breakdown due to excessive heat.

How Do Additives Affect the Cast Iron and Ductile Iron Properties?

The additives are incorporated to enhance their properties:

- Nickel and Titanium – Contributes hardness and strength.

- Chromium and Molybdenum – Contributes corrosion resistance.

- Manganese – Increase thermal strength.

- Boron – Increase formability.

- Silicon – Lighter weight and cost.

- Nitrogen – Enhance fracture toughness.

Cast Iron vs. Ductile Iron: In What Ways Are They Different?

| Property | Ductile Iron | Cast Iron |

| Composition | Nodular graphite, carbon, and silicon | Graphite flakes, carbon, and silicon |

| Strength | Higher tensile strength and flexibility | Higher compressive strength, less ductile |

| Brittleness | Less brittle, more malleable | Prone to fractures under stress |

| Impact Resistance | Excellent impact and vibration resistance | Susceptible to cracking under stress |

| Corrosion Resistance | More resistant in harsh environments | Requires coatings to prevent rust |

| Cost | More expensive | More cost-effective |

| Common Uses | Pipes, automotive parts, flexible components | Engine blocks, cookware, rigid structures |

How to Select Cast Iron or Ductile Iron?

1. Strength and Flexibility Test

- Cast iron is employed for compressive strength.

- Ductile iron is employed for tensile strength and flexibility.

2. Environmental Conditions Test

- Ductile iron is employed in corrosive conditions.

- If rigidity is the issue, employ cast iron.

3. Test for Cost Factors

- Cast iron is economical at the initial stage, the most suitable option for cost-planned installations.

- Maintenance cost is not included in ductile iron with improved ROI in later stages.

4. Do Not Neglect Weight Factors

- Where weight factor is involved, ductile iron is almost light.

- Cast iron never comes to a specific point of use when considering weight.

Improved Pipeline Solutions? Then use Conflex Joints

Conflex Joints is the only company with such faith to be relied upon for industrial fittings and fixing material even up to over 15 years. Conflex began its enterprise at Yingkou in China, and its faith is to serve good-quality product and efficient service.

Why to Choose Conflex Joints?

- Range of Products – More than 500 range of product for entire range of application in industries.

- Industrial Experience – Whole R&D team for Industrial Experience – constant innovation.

- Quality Assurance – Hire independent testing lab like SGS and BV.

- Spectacular Support – Offers installation manuals and post-sales service.

- Simplified Manufacturing – In-house coating and casting lab to provide quality production.

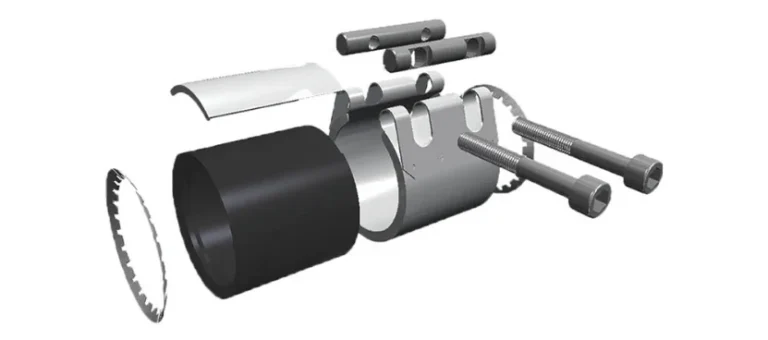

Product of the Day: Ductile Iron Flat Flange/Weld Flange

Conflex Ductile Iron Flat Flange/Weld Flange is particularly well suited for:

- Water and drainage supply

- Oil and gas pipeline

- Heating and air condition

- Chemical and food processing industries

A PN10, PN16, and PN25 rated flange is thus best suited to be used in high pressure.

Conclusion: Which of Them Do You Need to Pick

Cast iron and ductile iron will be based on what your application is calling for specifically. Ductile iron will be your choice when toughness, impact strength, and elasticity are needed. Cast iron will be your choice when economy, compressive strength, and stiffness are needed.

Conflex Joints offers affordable, high-performance pipe coupling products in the form of inexpensive, durable, and reliable products to meet your industrial needs.