A piping system is a process in which several basic steps are being followed in its installation process, and proper flange fitting is required to the strength as well as safety of systems. Flanges are fittings through which pipes, valves, pumps, and other equipments are connected by couplings with them for avoidance of failure or leakage in systems.

What Are You To Do While Choosing Flanges?

How Do You Select the Proper Flange Type and Material?

The initial process of flange installation is the selection of the proper type and material for the particular project. The following factors should be considered:

- Pressure Rating:The operating pressure of the system must be compatible with the flange’s ability to sustain it.

- Material Compatibility:Choose the flange material compatible with the fluid to be conveyed. The most popular materials are stainless steel, carbon steel, and specialty alloys.

How Do You Prepare the Pipe Ends for Installation?

Why Do You Clean the Pipe Ends?

Cleaning the pipe ends and flange faces before installation is a must. It removes debris and surface defects that will prevent the seal. Correct preparation prevents uneven stress distribution and leakage.

How Do You Align Flanges?

Carefully align the flanges and place the gasket in its correct position between them. Misalignment causes system instability, which leads to operating inefficiencies and potential failures.

How Do You Fasten Flanges Correctly?

Why Do You Tighten in a Cross-Pattern Sequence?

Tighten flanges in a cross-pattern sequence to achieve even clamping force distribution. This will avoid warping and give an even seal.

How Do You Properly Use Torque?

Use a torque wrench to observe the manufacturer-specified torque figures. Over-tightening causes distortion of the flange and under-tightening causes leakage. Double check torque figures to ensure sealing.

Why Use Conflex Flange Adaptors?

Why is Conflex a Good Choice for Pipeline Connections?

Conflex Joints is a high-quality industrial pipeline connector and repair solution manufacturer. Conflex has more than 15 years of history and is famous for its excellent quality engineering solutions for the majority of engineering needs.

What Are the Main Benefits of Conflex Products?

Conflex adaptors are simple to fit, give fast repair, and require less maintenance. Conflex adaptors are WRAS-approved, hence appropriate for potable drinking water use.

Conflex always strives for improvement and innovation in products in order to become the world’s most professional pipeline connecting service company.

What Materials are Used by Conflex Flange Adaptors?

Flange Pipes & Gland Flanges: Made of high-quality GGG50 material.

Rubber Gaskets: In EPDM, SBR, and NBR for special applications.

Bolts & Nuts: Of carbon steel or stainless steel with fusion bond epoxy coating for corrosion protection.

What Standards Do Conflex Products Adhere To?

Conflex products are made in accordance with international standards, such as:

- EN1092-2, EN1092-1, and ANSI for drilling flanges

- EN30677 for coating

- EN12266-1 for testing·

Does Conflex Provide Custom Solutions?

Yes, Conflex provides custom solutions to suit individual customer requirements. Their qualified R&D department can develop custom solutions as per individual project needs.

How Do You Install a Quick Flange Adaptor Efficiently?

Step 1: How to Choose the Right Size?

Choose the quick flange adaptor by the outside diameter of the HDPE pipe. The right size is marked on the adaptor body (e.g., PE/PVC xxx, where xxx is the diameter).

Step 2: How to prepare the parts?·

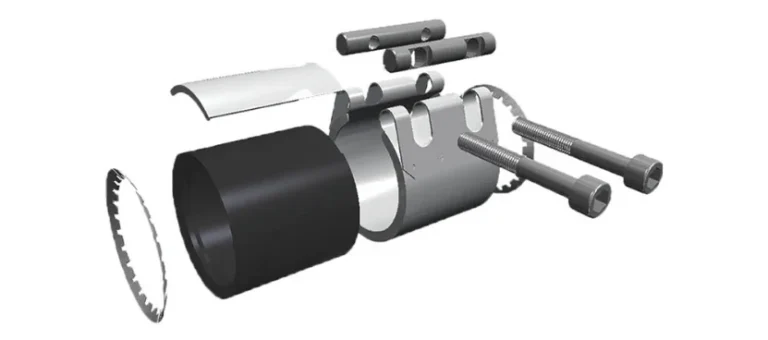

Remove the grip ring and gasket from the flange adaptor.

Insert the flange body onto the PE pipe.

Step 3: How to Insert the Grip Ring and Gasket?

Insert the grip ring, followed by the gasket.

Make sure the end of PE pipe is seated on the lower blocking platform of the gasket.

Step 4: How to Insert the Gasket in Proper Way?

Seat the flange body to fit in the gasket.

Push the gasket firmly into the inner bore of the flange body by means of a rubber mallet.

Step 5: How to Tighten and Place the Bolts?

Place the flange adaptor over the mounted flange.

Secure bolts diagonally such that bolts get tightened in equal measure until the gasket is compressed tightly.

Step 6: How to Perform a Leak Test?

Slowly build pressure and monitor for leakages.

Where there is leakage, stop pressure and tighten bolts until a solution is met.

What are the Steps for PVC Pipe Installation?

Step 1: How to Choose the Right Size

Choose the right quick flange adaptor based on the outside diameter of the PVC pipe. The size is printed on the body of the adaptor.

Step 2: How to Prepare the Components?·

Remove the gasket from the quick flange adaptor.Put the flange body over the PVC pipe. (No grip rings for PVC pipes.)·

Step 3: How to Position and Insert the Gasket?·

Place the gasket over the PVC pipe and push it in place.Make sure the lower end of the PVC pipe drops to the blocking platform of the gasket at the bottom.

Step 4: How to Install the Gasket?

Place the flange body into place.Push the gasket into the inner cavity of the flange body with a rubber mallet.

Step 5: How to Install and Tighten the Bolts?

Place the flange to the flange to be assembled.Tighten the bolts in a diagonal pattern to get an even seal.

Step 6: How to Perform a Leak Test?·

Slowly build up pressure and check for leaks.Re-tighten bolts, if needed, until the system is leak-free.·

What Are Some Other Tips for a Safe Installation?

How to Optimize Pipe Preparation?·

Clean the pipe surface at least 12 inches from the end.·

Remove any defects that will prevent the gasket seal.·

What Is the Role of Lubrication?·

Use soap and water on pipe and gasket face for installation assurance.

Utilize antifreeze at freezing temperatures to avoid gasket hardening.

How to Apply Proper Torque?

Torque the bolts initially to 50 ft-lbs.

Final torque will be 70 ft-lbs for 5/8″ bolts and 90 ft-lbs for 3/4″ bolts.

Re-torque after application of fluid pressure and then fine-tune accordingly.

What are Universal Flange Adaptors and What are they used for?

A universal flange adaptor enables connections on pipelines by accommodating varying pipe diameters. It is best used for:

- Rapid installation and un-installation

- Universal use in various materials of pipes (steel, iron, plastic)

- High working pressures (PN10/PN16/PN25) management

- Use in potable water, sewage, and neutral liquids

- Corrosion resistance and angular flexibility of +/- 6 degrees

If you follow this guide, you will be able to achieve a safe and long-duration flange installation on your piping system.