When designing or maintaining an industrial piping system, selecting the right connection method is critical for ensuring both efficiency and safety. Among the most commonly used solutions are flange adaptors and couplings. Both play vital roles in the connection, repair, and maintenance of pipelines, but each comes with unique features that can make one more suitable for certain applications than the other.In this article, we will explore the differences between flange adaptors and couplings, highlighting the advantages and disadvantages of each and providing guidance on which is the best choice for your specific system needs.

Understanding Flange Adaptors and Couplings: What Are They?

To understand which device is best in a particular use, first consider what each element is and the role they would play in pipeline systems.

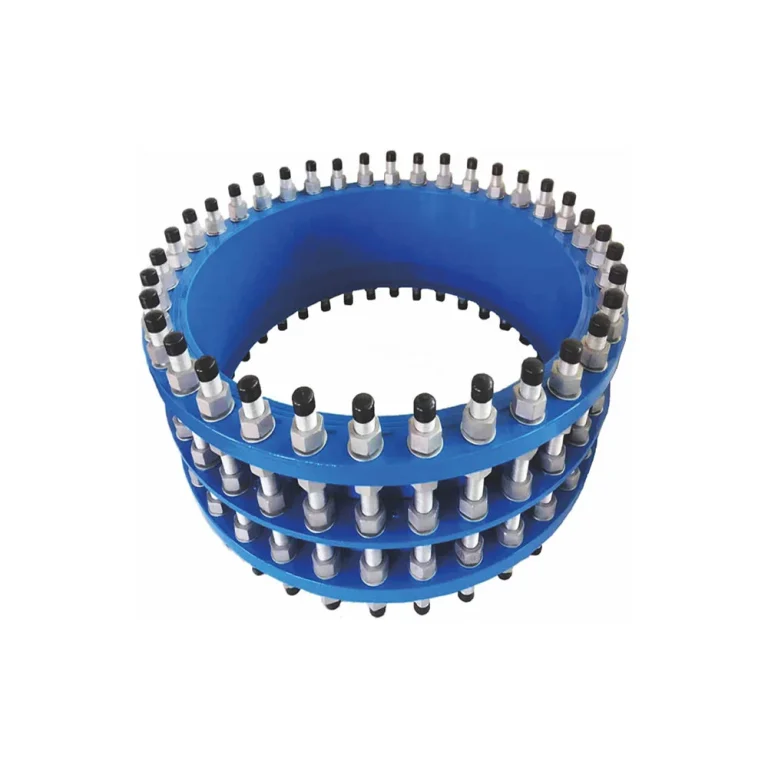

A flange adaptor is a mechanical coupling that has one end flanged a flat, usually circular plate with holes for bolts-and the other end set up for a socket or other type of pipe. It is widely used in systems where one end of the pipe is already flanged, and the other end requires a flexible or quick connection.

A coupling is a looser term that describes any fitting used to connect two sections of pipe. Couplings may connect pipes of the same or different diameters, and generally available with threaded, bolted, or other type fasteners.

Flange Adaptor vs Coupling: Which Is Better for Your System?

1. Applications and Flexibility

This is why the choice between flange adaptors and couplings will highly depend on the system you are using. For instance, where you require an extremely strong and long-lasting connection-for example, pipes of various diameters, and pipes produced with different materials-a flange adaptor would be required. In addition, the applications of flange adaptors can also be found in water supply systems, sewage systems, and industrial piping systems where flanges have already been installed.

Flange adaptors are particularly useful for applications in which you have pipes that have flanged ends, including steel, iron, and plastic. Flexibility is derived from the fact that these adaptors can accommodate different diameters of pipes and kinds of materials, thus allowing for effective installation and easy adjustment. Besides, Conflex Joints is one of the largest manufacturers of pipeline connection products. It offers a wide range of flange adaptors that can resist pressures to PN25, are corrosion-resistant, and perfect for use in potable water systems, neutral liquids, and even sewage.

Conversely, couplings are usually the answer for systems that are much more straightforward, where simplicity is essential. They are generally used when there is a need to connect pipes together in a hurry without the complication of adding a flange connection. In cases where the strength and flexibility of a flange are not required, then a coupling may be sufficient. However, in general, couplings are not as adaptable as flange adaptors in terms of the type of pipe and pressure rating.

2. Ease of Installation

One of the primary differences existing between flange Adaptors and couplings is in ease and duration of the installation process. Flange Adaptors go a step ahead, especially for those provided by Conflex Joints, to reduce time during installation. As explained in detail, their product is engineered to accomplish fast and swift installation. The professional can easily connect a piped end flanged to socketed or different materials using this product. This feature is particularly beneficial for maintenance operations where downtime must be minimized.

Couplings are, however, mostly simpler and faster to install for less complicated systems, especially if one is working with small-sized pipes or simply needs a temporary connection. They usually require less space and may not always necessitate bolts or any other fittings to create a tight seal. However, they are not always as adaptable or capable of handling the same range of system stresses as flange adaptors.

3. Durability and Strength

Flange adaptors are tougher than couplings in terms of durability. This flange adaptor actually forms a connection that is quite stronger and sure, especially during high-pressure systems and extreme environmental condition. For example, the universal flange Adaptor from Conflex Joints will have a work pressure of PN10, PN16, PN25, thus best suited to industrial and municipality applications. It is also resistant to corrosion, hence can ensure service life even in very harsh environments like sewage treatment plants or water supply systems.

Couplings work reliably for most standard applications but cannot provide the same level of security or pressure endurance that can be derived from a flange adaptor. Where the system requires high resistance to pressure or temperature, sometimes flange adaptors will be a better option owing to their added strength.

4. Maintenance and Repair Considerations

The flange Adaptors work with those systems that may require maintenance, where pipes may often need to be replaced. Their repairs are, therefore, pretty easy to manage by removing or adjusting during need, while their strong builds further minimize chances of system failures.

Couplings are also good for maintenance, but they tend to be a bit more limited in their flexibility. While they can be used to repair minor issues or join two pipes together temporarily, they might not be as reliable for systems that need frequent adjustments or that face varying operating conditions over time.

Why Choose Conflex Joints for Your Flange Adaptor and Coupling Needs?

For businesses requiring competent and compliant pipeline connection solutions, Conflex Joints is one of the best options with outstanding product ranges that could meet the toughest industrial standards. With over 15 years of experience in the manufacturing of pipeline products, Conflex Joints has established a reputation in providing high-quality, efficient, and cost-effective solutions.

Conflex Joints’ Universal Flange Adaptors are specifically designed to ensure durability, easy installation, and versatility. There are various sizes and pressure ratings of adaptors designed for a variety of pipe materials. The adaptors connect steel, iron, and plastic pipes and, due to their resistant structure, assure long-lasting and reliable performance, even in very aggressive conditions.

Conflex Joints also manufactures special flange adaptors for HDPE, PVC, and DI pipes and even adjustable models intended for PE pipes. This gives businesses a wide range of options to satisfy various requirements in fields such as municipal water systems and industrial piping operations.

What’s more, with Conflex Joints, satisfaction is ensured not only with the top-of-the-range products but also with excellent after-sales service, technical support, and solutions given for improvements in the effectiveness of piping systems.