Infrastructure and pipeline industries have to come up with efficient, cost-effective, and durable solutions both in construction and maintenance. Here comes the role of dismantling joints-important and timely innovation aimed at saving time, reducing costs, and enhancing the overall adaptability of projects. From potable water systems through sewage pipelines to large-scale industrial projects, dismantling joints are a key feature of modern engineering and construction processes.

The following article looks at how dismantling joints are changing the face of pipeline projects through the help of industry insight, relevant data, and case studies. We will also be looking at how Conflex Joints is a leading manufacturer within the pipeline industry that’s offering state-of-the-art solutions to future-proof businesses.

Why Dismantling Joints Are a Game Changer

The Basics: What Are Dismantling Joints?

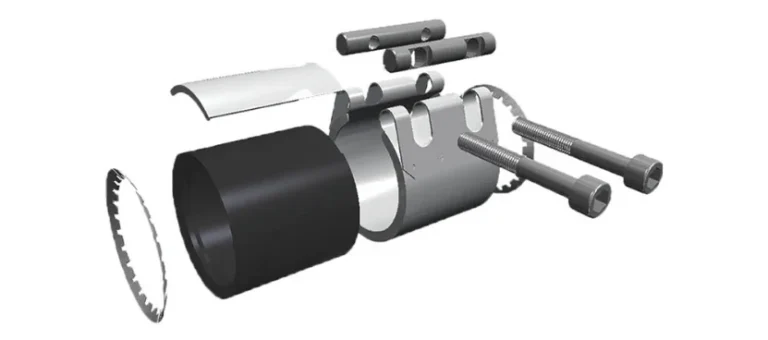

Dismantling joints are very versatile fittings that connect pipes, valves, and other components of the pipeline system. The ability of the length adjustment makes dismantling joints crucial in simplifying the installation and removal of major components. Their field of application covers pipeline maintenance, repairs, and upgrades. They allow axial and lateral adjustments at the time of installation, hence minimizing problems with alignments and thereby reducing total downtime.

Practical Benefits of Dismantling Joints

1.Time-Saving Installation

Traditional pipeline installations often involve time-consuming alignment and fitting processes. According to a report by theWorld Pipeline Association, 25-30% of project delays stem from misaligned pipes and poorly designed connection systems. Dismantling joints eliminate these issues by offering adjustable lengths and easy alignment, cutting installation time by up to 40%.

2.Cost Efficiency Through Simplified Maintenance

Maintenance is one important aspect of pipeline management. For instance, dismantling joints are useful in offering quick access to inner components of the pipeline, including valves and pumps, while dislodging major constructions. Actually, the maintenance costs on large-scale projects of water supply were reported by Pipeline Technology Journal, which were reduced through the application of dismantling joints by 25% accordingly.

3.Applicability on Different Operations

Dismantling joints are ideal for potable water systems, recycled water, and sewage pipelines. The corrosion-resistant structures and compliances with international standards make the dismantling joints highly suitable for industries that range from municipal waterworks to oil and gas pipelines.

Demand for Dismantling Joints in Modern Industries

Growth in Pipeline Infrastructure Investments

According to the, the demand for investment in pipeline infrastructure will exceed US$1.6 trillion by 2030, driven by rapid urbanization and growing demands for competent water and energy supplies. Dismantling joints are certainly at the front rank in this growth, providing solutions to help address the changing needs of such industries.

Case Study: The Malonga Water Supply Pipeline Project in Malawi

The Malawi Kalonga project supported by Conflex Joints utilized dismantling joints to facilitate easier installation of a modern water supply system. The adjustability inherent in the joints reduced the installation time by 35% and provided long-term reliability under various pressure conditions.

Renewable Energy Projects and Pipeline Flexibility

This has also driven the demand for renewable pipeline solutions, such as increased adoptions of wind and solar energy. Examples include dismantling joints in underground pipelines for the transportation of renewable fuels that can withstand extreme temperature fluctuations for stability and performance.

How Dismantling Joints Enhance Sustainability

Reduced Material Waste

One of the key benefits of dismantling joints is their contribution to sustainability. Most traditional pipeline systems involve rework or replacement of misaligned parts, which often means material waste. The dismantling joints, by providing precise adjustments, minimize the need for replacement parts and reduce overall material waste.

Compliance with Environmental Standards

Dismantling joints from manufacturers likeConflex Joints meet rigid international standards such as EN12266-1 for testing and WRAS certification to ensure that products are suitable for potable water applications. Such certification ensures that the products meet the necessary requirements with respect to environmental and safety concerns and are, therefore, suitable for any sustainable infrastructure project.

The Role of Conflex Joints in Revolutionizing Pipeline Solutions

About Conflex Joints

Headquartered in Yingkou, Liaoning Province, China,Conflex Joints is one of the world’s largest manufacturers of pipeline connection and repair products. With more than 15 years of experience in the field, Conflex has grown with innovation, quality, and customer satisfaction. Its R&D team develops products in response to market demands and eliminates design defects to ensure adaptability and reliability.

Advantages of Conflex Dismantling Joints

1.Custom Designs to Suit Applications in Various Fields

Conflex offers custom designs for dismantling joints to suit various industries and applications. From potable water systems to sewage pipelines, Conflex’s products offer versatility and performance like no other.

2.High-Quality Materials and Standards

To ensure durability and resistance against corrosion, Conflex uses advanced materials such as GGG50 cast iron and EPDM/SBR/NBR rubber gaskets. Products from the company have complied with international requirements such as EN1092-2 for flange drilling and EN30677 for coating, thus suitable in global markets.

3.Efficient Production and Delivery

Having its own workshop for casting and spraying, the production cycle at Conflex is smooth and ensures quick delivery. Every piece is accurately packed to ensure quality during its transportation.

Applied Uses of Conflex Dismantling Joints

Large-Scale Projects Supplied by Conflex

Debrebrhan University Water Supply Project: Conflex dismantling joints played an important role in the successful and efficient installation and for long-term reliability of the water supply system at the university.

Kafulafta Project in Zambia: Thanks to Conflex dismantling joints, the project saved from serious alignment challenges and reduced the time of installation drastically.

JET-A1 Underground Pipeline Construction, Bangladesh: Variable length of Conflex dismantling joints provided the flexibility to solve the installation issues in such a complicated context.

Why Conflex Can Be a Partner of Your Pipeline Requirements

Excellent Customer Care

At Conflex, the services extend beyond mere product supply to include pre-sales technical consultancy, installation guidance training, and after-sales services. This customer-oriented business model makes sure that no customer lacks relevant assistance during a project cycle.

Proven Performance

With certifications from international agencies such as SGS and BV, Conflex has grown to become a well-recognized partner in the global pipeline industry. Their WRAS-certified products stand to point out their dedication to the quality and safety of their production.

Conclusion: Future-Proof Your Projects with Conflex Dismantling Joints

The dismantling joint is no longer an option in the modern development of infrastructural and pipeline projects but a necessity. It saves time, it is cost-effective, and above all, provides unparalleled flexibility.

If there’s ever a need for dismantling joints, be rest assured that Conflex Joints will take center stage. From its comprehensive portfolio of the best quality, offering special designs to delivering quality customer care, Conflex secures projects for your future: more efficient and environmentally friendly.

Introduce yourself today to dismantling joints at Conflex and take the necessary stride toward optimizing your pipeline projects. Visit them on their website or directly with their consultation team.