In today’s industrial scenario, pipeline efficiency is a major concern to minimize operational costs, reduce downtimes, and ensure longevity with a leak-free system. Be it water, gas, oil, or chemical pipelines, the selection of appropriate components is very important to achieve these objectives. One such important component involves the saddle clamp, a product designed to enhance the installation, maintenance, and efficiency of pipeline systems.

The following blog post discusses some reasons why saddle clamps are very important for ensuring the utmost performance of pipelines. Applications, advantages, and more are discussed here to convince you why it must form a part of your upcoming project. Further into the course, we also introduce Conflex Joints, one of the high-quality manufacturers of the finest range of pipeline solutions offering products that enable the users to install these at their premises quicker, smoother, and economical.

Introduction: Importance of Efficient Pipeline Solutions

Pipelining systems form the backbone of many industries that range from water treatment to gas supply and even to chemical transportation. The efficiency, however, in a pipelining system basically depends on the component quality used for assembling such pipelines. Talking of pipe connections, a saddle clamp can be considered one of the most effective solutions found in today’s time.

Saddle clamps are designed for the secure and leak-proof connection between pipes. Installation of branch pipes or any additional new equipment can be enabled without disrupting the flow inside. Such designs guarantee flexibility, durability, and ease of installation-the three quintessential features that justify it as an indispensable tool within the frame of modern piping systems. Sectors which require continuous pipework functionality, such as water utilities or oil and gas industries, depend on the saddling reliability and convenience.

Understanding Saddle Clamps: The Basics of this Important Pipeline Component

First, let’s take a closer look at what saddle clamps are and how they work.

What is a Saddle Clamp?

A saddle clamp is a special type of connector used in creating a branch from an existing pipeline. This kind of clamp is normally set up around the outside of a pipe, thus making a strong connection without necessarily having to make many modifications, welding, or even cutting of the pipe. Saddle clamps are versatile and can be used on a variety of materials, including ductile iron, PVC, PE, and steel pipes.

The saddle clamp provides easy accessibility to the pipeline, which can be utilized in installing equipment such as faucets, water meters, or branch lines. A particular advantage is when situations arise where shutdown of the complete pipeline system would be utterly impracticable or too expensive.

Types of Saddle Clamps

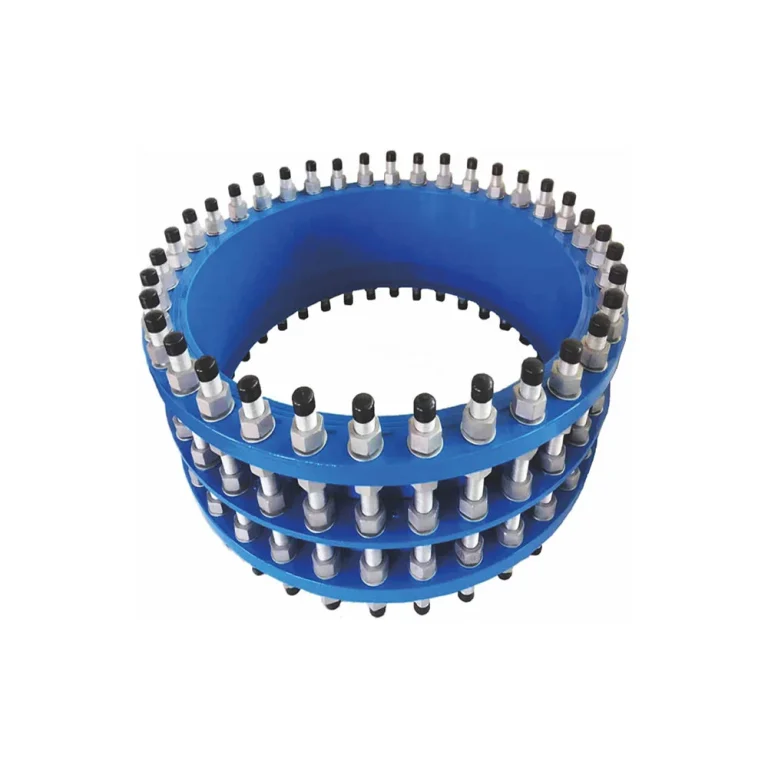

The Universal Saddle Clamps provide for DN50 to DN700 pipe materials, from which a wide size variation can be fitted besides having the flexibility required in clamping onto the pipe outer wall for easy installation, secure, and free of leakage.

It is a type of clamp best suited for conditions under which you would need to branch off a pipeline or put up a meter with least interruption to the running operation of the system.

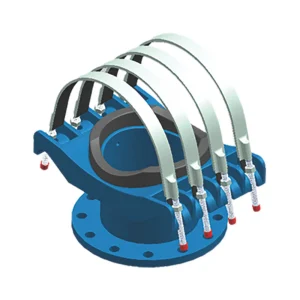

Universal Saddle Flange Tee Clamps: These are specially designed to connect branch lines to pipelines or to install accessories like faucets and water meters. Available from DN80 to DN1000, they feature a quick installation design that can be done with just a wrench and a torque wrench.

It means both kinds of saddle clamps can be installed on running pipelines without causing any disruption to the running pipeline, thus making them an ideal choice for maintenance or system upgrades.

Key Benefits of Saddle Clamps in Pipeline Systems

Now that we understand what saddle clamps are, let’s look at the specific benefits that they have for pipeline projects.

1. Cost-Effective Installation

Cost-effectiveness may be one of the major reasons businesses opt for the application of saddle clamps. Most of the earlier methods of branching off a pipeline involve expensive procedures, including welding or even cutting, and can result in enormous losses due to much-valued downtime. With a saddle clamp, it’s possible to create a branch line without extensive modification; hence, there is substantial saving on both labor and materials.

Saddle clamps also minimize the risks of costly mistakes and resultant repair costs by dispensing with the need to cut and weld pipes. These saddle clamps are thus designed to be compatible with various types of pipe materials, thereby ensuring that a single type of fitting can be stocked for several piping systems, further reducing inventory costs.

2. Easy to Install and Speedy

Saddle clamps are considered to be easy to install. By design, they can be fitted onto existing pipelines quite easily without requiring any kind of specialized skill or equipment. The Universal Saddle Clamps from Conflex Joints, for instance, can be installed using just an ordinary wrench, which reduces installation time by a huge margin compared to conventional methods.

3. Versatility and Compatibility

Saddle clamps are quite versatile in many ways. They work perfectly with a variety of pipes, including ductile iron, PE, PVC, and steel, all under the same nominal diameter. Because of that, engineers and project managers may facilitate ease in the installation process by not necessarily having to think of procuring other kinds of clamps for different pipe materials.

Conflex Joints offers Universal Saddle Clamps that can be used across multiple pipe types, including DI/PE/PVC and steel pipes, allowing you to reduce the number of components needed for your pipeline installation. This compatibility is a game-changer for businesses looking to reduce inventory costs and simplify their project workflows.

4. Leak Prevention and Durability

Saddle clamps create strong, leak-proof seals, which offer great integrity to your pipeline system. Further, the use of high-strength bolts and customized options of gaskets such as EPDM, SBR, and NBR offers superior sealing characteristics at higher pressures, enabling one’s pipeline to be secure with less leakage and expensive water losses.

Saddle clamps supplied by Conflex Joints are fabricated to the highest international industry standards with certification to BS, EN ISO9001:2008, and WRAS for use in drinking water applications. Quite apart from businesses involved in the supply of water and sanitation, it’s a serious consideration for anyone operating an industry reliant on high quality water.

How Saddle Clamps Can Improve Your Pipeline’s Efficiency

Having outlined the benefits, let’s now dive into how saddle clamps contribute directly to pipeline efficiency.

1. Less Downtime

As earlier mentioned, one of the striking features of saddle clamps is their ability to be installed on running pipelines without a system shutdown. This feature is priceless in industries where operations cannot afford to stop, such as water utilities, gas distribution, and chemical manufacturing. By allowing quick modifications without disruption, saddle clamps help maintain system efficiency and reduce downtime.

2. Enhanced Pipeline Performance

With safe and leak-free connections, the saddle clamp improves the overall performance of your pipeline system. Leak and no pressure loss are two main causes that reduce any system’s efficiency and service life. Saddle clamps keep up the optimum flow rate since tight sealing is maintained; such a flow rate is often crucial for applications such as water treatment or gas distribution.

3. Simplified Maintenance and Upgrades

Saddle clamps make pipeline upgrades or maintenance a piece of cake. Since they are easy to install or remove, they facilitate the addition of new equipment in an existing pipeline, such as water meters or faucets, without having to reconfigure the system much. In this way, upgrading on the fly can save time and money by making your pipeline more adaptable to changing needs.

Why Choose Conflex Joints for Your Saddle Clamp Needs?

If you’re looking for high-quality, durable saddle clamps for your next pipeline project, Conflex Joints is the ideal partner. With over 15 years of experience in the pipeline connection industry, Conflex Joints is a trusted name known for providing innovative and reliable solutions.

Their range of Universal Saddle Clamps and Universal Saddle Flange Tee Clamps are fabricated to the highest standards for quality, thus ensuring pipeline systems remain effective, leak-proof, and durable. The reasons to get Conflex Joints on board with your coming project are explained below.

- WRAS Certified: Drinking water compatibility.

- Easy to Install:Quicker installations, no complications, can be installed using basic tools.

- Durable:Fabricated from high-tensile material, such as ductile iron and stainless steel.

Conclusion: Improve the Efficiency of Pipeline Systems using Saddle Clamp

Saddle clamps are important elements in pipeline systems, offering increased efficiency, reliability, and flexibility. Be it a new installation or renovation of an existing one, these components facilitate ease of the process, reducing downtime and costs. With advantages such as ease of installation, leak prevention, and compatibility with