The terms dismantling joints and expansion joints are often tossed around when either performing maintenance or installing pipeline systems. Both are parts that are instrumental for different reasons, but these terms are often confused with one another. While both do contribute to the flexibility, and thus durability, of piping systems, they perform their functions for different reasons. So, are dismantling joints and expansion joints the same? Great, let’s explain the differences, what each one does in pipeline management, and how they can help attain a more reliable and efficient system.

In this article, one will go through not only the in-depth view of both kinds of joints but also the specifications and advantages of Conflex’s Dismantling Joints, one of the leading choices for the pipeline industry.

What is a Dismantling Joint?

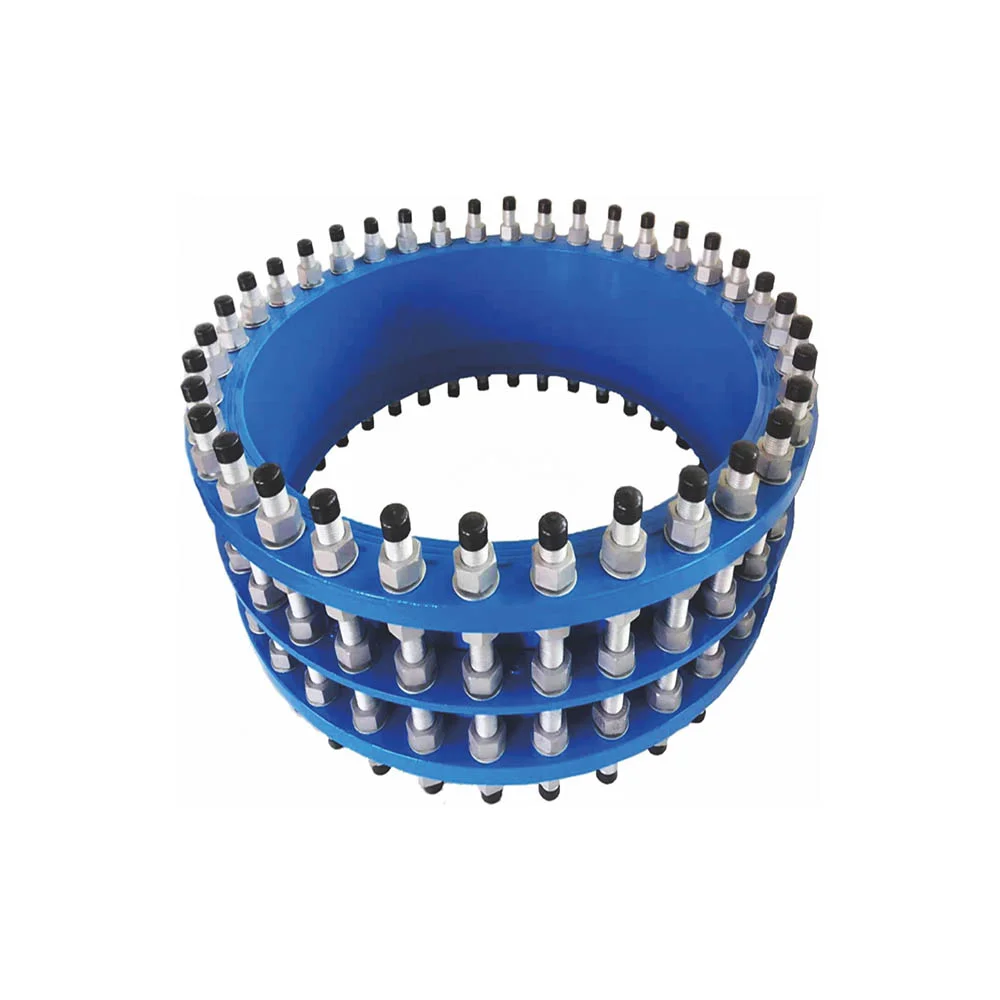

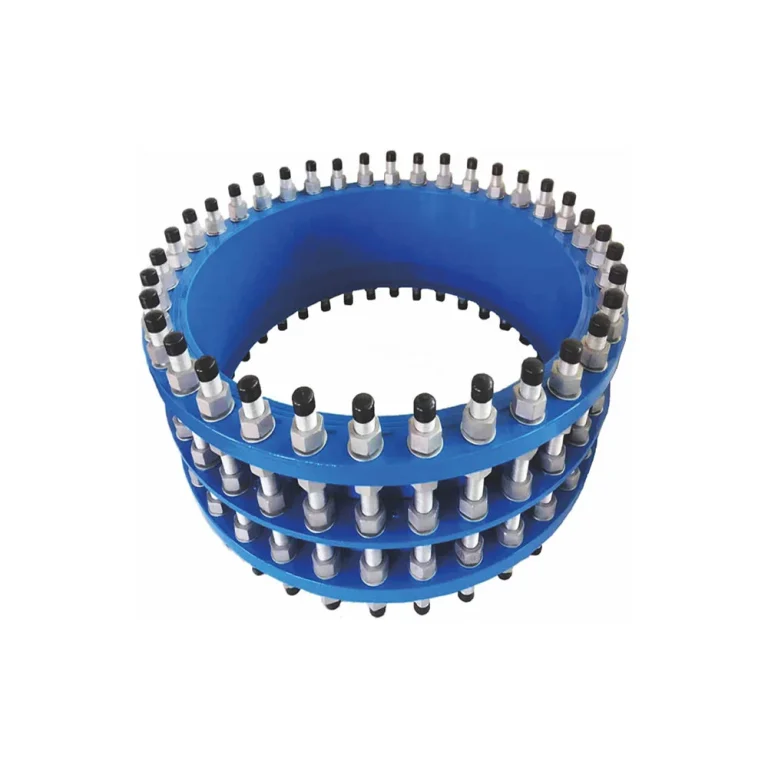

The dismantling joint plays a critical and versatile part in pipeline applications. A dismantling joint is employed, for example, in the primary function of easily connecting two flanged pipes or fittings. Dismantling joints have been created for easy pipeline disassembly without dislodging any part during maintenance or alterations to be done within the whole pipeline system. DI Dismantling Joints made by Conflex come with adjustments so that the length can be altered by users according to the needs required during on-site installation. This flexibility makes them indispensable in working with a variety of piping materials, such as steel, iron, or plastic.

Key Functions of Dismantling Joints:

- Easy Installation and Maintenance:The main function of the dismantling joint is for easy detachment and attachment of the pipeline sections. In such cases, it is necessary when one valve, fitting, or any other component of a pipeline has to be replaced without removing the entire section of the pipeline system.

- Adjustable Length:Dismantling joints can be adjusted for various lengths; hence, they are highly adaptable to field variations and complicated pipeline configurations. This greatly reduces installation time and therefore the cost.

- Diverse Application:Dismantling joints find wide applications in water and wastewater systems where pipelines need extension or maintenance very often.

Conflex provides dismantling joints in the range of DN50 to DN2000 and for different pressure classes such as PN10, PN16, PN25, and PN40. Due to the nature of their construction, including ductile iron bodies, EPDM/SBR/NBR gaskets, and corrosion-resistant coatings, they are durable for extended service life, even under the most adverse conditions.

What Is an Expansion Joint?

An expansion joint is designed to absorb and manage expansion and contraction of the pipes due to temperature fluctuations, pressure changes, or physical movement. Unlike dismantling joints, expansion joints basically focus on affording flexibility to the pipeline in order to oppose the forces that arise due to temperature changes or external stresses.

Key Functions of Expansion Joints:

- Absorbing Thermal Expansion and Contraction:As pipes heat up or cool down, they expand or contract. Expansion joints are designed to absorb such movement without compromising the structural integrity of the system.

- Vibration Damping:Other than absorbing thermal movement, expansion joints are designed to dampen vibrations from pumps, compressors, and other equipment within the pipeline system. This limits the chances of damage to both the pipeline and machinery.

- Pressure Variations Management: Changes in pipeline pressure also represent stress to the system. Expansion joints minimize this by introducing flexibility into the most affected areas.

Key Differences Between Dismantling Joints and Expansion Joints

While both dismantling joints and expansion joints serve to enhance the efficiency and lifetime of any pipeline system, they do so differently. Understanding such differences will make it easier to select the correct joint for your application.

- Purpose:

Dismantling Joints find their main application in the field of maintenance, disconnection, and reconnection of pipeline sections, enabling access for easier repair and adjustments.

Expansion Joints its purpose is to absorb the movement of the pipe-thermal expansion, contraction, and vibrations-to avoid damage due to pressure or environmental factors.

- Flexibility:

The Dismantling Joints can be adjusted according to length variations in the pipeline. This accommodates easy installation and maintenance.

Expansion Joints are flexible to absorb the movement but do not provide quite the same degree of length modification as dismantling joints. The flexibility of these is more to do with the management of physical forces rather than easy removal or installation of pipe sections.

- Installation and Maintenance:

Dismantling joints reduce installation work since on-site installation and adjustments are easily carried out with these types of joints at repair time; the case in systems when frequent changes or improvements are performed.

Expansion joints are mounted for long-time stability at varying temperatures or changing pressure and normally don’t need maintenance except in cases where abnormal stress and/or movement is put on the system.

When to Use a Dismantling Joint vs. an Expansion Joint

Whether to use a dismantling joint or an expansion joint in a pipeline depends on the need for either in the system:

Dismantling Joints: These are indispensable in systems where maintenance, modification, or easy disconnection is required. For instance, if your pipeline system includes regular servicing components, or it’s a water distribution system where you need to change valves or faucets, dismantling joints would make the process quite easy. Moreover, the adjustable length feature in dismantling joints by Conflex allows for on-site variation to be accommodated for a proper fit, even in very complex configurations.

Expansion Joints: These are usually applied in high-temperature systems or pipelines that are subjected to extreme environmental changes, such as power plants, chemical processing facilities, or water treatment plants. If your pipeline is subjected to extreme temperature fluctuations, pressure changes, or even vibration, then expansion joints are a must to avoid stress and possible damage to the system.

The Conflex Advantage: Why Choose Conflex Dismantling Joints?

Conflex is the leading manufacturer of pipeline joints, including dismantling joints, serving a wide range of industries, from water treatment to irrigation systems. Here is why the DI Dismantling Joints from Conflex stand out:

- Custom Designs: Conflex does provide custom-designed solutions to fit particular project requirements and ensure a perfect fit for your pipeline system.

- Quality Materials: Made of ductile iron and fitted with high-quality rubber gaskets-EPDM, NBR, or SBR, Conflex dismantling joints are designed to be durable enough for the most challenging applications.

- Flexibility and Ease of Installation:Conflex dismantling joints have adjustable lengths for better on-site fitting, and no special tools are needed for installation other than a simple wrench.

- Resistance to Corrosion:Conflex’s dismantling joints have been built with advanced protection systems like Fusion Bond Epoxy and materials of high strength to withstand corrosion and other aggressive operating conditions.

- International Certifications: Conflex’s dismantling joints are WRAS approved-a warranty that they conform to the best international standards for use in potable water systems. This, therefore, means they assure the suitability of the dismantling joints in drinking water systems.

Industry Trends: The Growing Demand for Flexible Pipeline Solutions

A report by Research and Markets in 2022 estimated that the pipeline market would continue to grow with the expansion of industries such as water supply, oil and gas, and wastewater treatment.

This trend should be augmented with the demand for more recent kinds of innovation, for example, Conflex dismantling joints offering reduced downtime and increased adaptability in view of an increasing trend toward sustainable infrastructure and smart pipeline systems.

Conclusion: How to Choose the Correct Type of Joint in the Pipeline System

While both dismantling joints and expansion joints play important roles in the integrity of pipeline systems, each has a specific function. Dismantling joints allow for maintenance, modification, and easy disconnection, while expansion joints take care of thermal movement, pressure fluctuations, and vibration. The choice depends on what your system requires.

For industries that require flexibility, reliability, and cost-efficiency in pipeline installations, dismantling joints by Conflex will be one of the best choices. With their adjustable length, corrosion-resistant construction, and WRAS approval, Conflex ensures your pipeline system stays robust, ready for any maintenance challenge.

From a well-trusted supplier like Conflex, you can have the best dismantling joints supplied by a committed team, applying itself continuously to offering the most innovative solutions for your needs.