Pipeline infrastructure is critical to industries and municipalities worldwide, enabling the transportation of water, gas, sewage, and even electricity. However, like any infrastructure, pipelines are vulnerable to wear, tear, and sudden leaks. For pipeline operators, the challenge lies in finding quick, reliable, and cost-effective solutions to repair these damages without disrupting operations. Enter mini repair clamps, compact yet powerful tools designed to tackle pipeline leaks with unmatched efficiency.

This blog explores the game-changing potential of mini repair clamps, their applications, and why they are indispensable for modern pipeline maintenance. By the end, you’ll understand why Conflex Joints is a trusted name in delivering high-quality mini repair clamps tailored to your business needs.

Why Mini Repair Clamps Are Essential for Modern Infrastructure

The Problem: Pipeline Leaks and Failures

Pipeline leaks and failures are not just inconvenient—they’re costly and potentially catastrophic. According to a 2021 report by Global Water Intelligence, water leakage alone results in a global loss of approximately $39 billion annually. Gas pipeline leaks are similarly concerning, with methane emissions posing significant environmental and safety risks, as highlighted by the International Energy Agency (IEA).

Addressing these issues requires tools that can perform quick fixes while minimizing downtime, and mini repair clamps excel in this role.

The Solution: What Are Mini Repair Clamps?

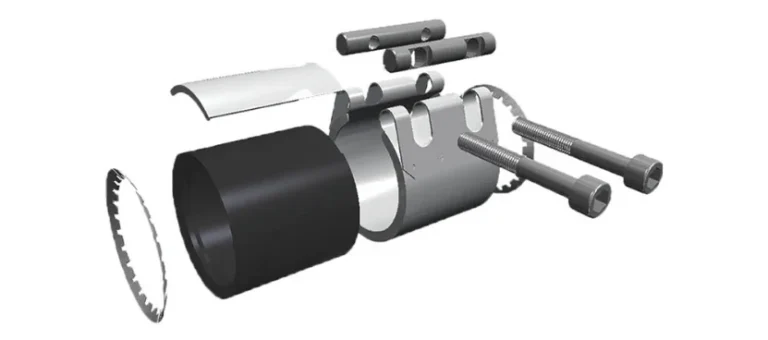

Mini repair clamps are compact, highly durable pipe repair tools designed to seal leaks and restore pipeline integrity. Their small size makes them ideal for repairing localized damage on pipelines in tight spaces or areas with limited access.

These clamps are available in two primary styles:

- Full Circle Mini Repair Clamps: Designed for 360-degree pipe coverage, offering complete repair for pipe ruptures.

- Semi-Circle Mini Repair Clamps: Ideal for smaller, more targeted leaks, requiring partial coverage.

Their versatility spans applications in potable water systems, sewage pipelines, gas distribution networks, and even electrical conduit repairs.

Small Tools, Big Advantages: The Benefits of Mini Repair Clamps

1. Fast and Efficient Repairs

Time is critical during pipeline emergencies, especially in industries like water distribution or natural gas. Mini repair clamps are designed for quick installation, requiring minimal tools and expertise. A 2022 study published in Pipeline & Gas Journal found that mini repair clamps reduce average repair time by 40% compared to traditional methods like welding or full-pipe replacement.

2. Cost-Effectiveness and Reduced Downtime

Mini repair clamps eliminate the need for costly shutdowns or major overhauls. For example, industries dealing with pressurized pipelines can install these clamps without interrupting operations, saving significant time and labor costs.

Supporting Data

- The American Water Works Association (AWWA)has reported that repair clamps reduce maintenance costs by up to 30% in municipal water systems.

- The International Gas Unionhighlights mini repair clamps as a preferred method in gas pipeline maintenance, reducing operational disruptions by 25%.

3. Versatile Applications Across Industries

Mini repair clamps are not limited to one type of pipeline. Their robust construction and adaptable design make them suitable for repairing pipelines transporting:

- Water: Potable and recycled water systems.

- Sewage: Durable enough to withstand corrosive substances.

- Gas and Natural Gas: Engineered to handle pressurized systems.

- Electricity: Used in conduit repairs to secure cables.

4. Compliance with Industry Standards

Conflex Joints’ mini repair clamps are WRAS-certified, ensuring they meet international standards for potable water applications. This certification guarantees that the clamps are safe, durable, and suitable for high-pressure environments.

How Mini Repair Clamps Ensure Sustainability

1. Material Efficiency

Unlike traditional repair methods that require replacing large sections of pipelines, mini repair clamps focus on localized fixes, reducing material waste. This aligns with sustainability goals by conserving resources.

2. Corrosion Resistance and Longevity

Mini repair clamps, such as those manufactured by Conflex, are made from high-quality materials like SS304 steel and NBR rubber gaskets. These materials are resistant to corrosion, ensuring the repair lasts for years without the need for frequent replacements.

Real-World Applications of Mini Repair Clamps

Case Study 1: Municipal Waterworks in Malawi

During the Malawi Kalonga Water Supply Pipeline Upgrading Project, Conflex Joints supplied mini repair clamps to fix leaks in critical water pipelines. The compact size and quick installation of these clamps enabled the project team to repair multiple leaks in record time, reducing water loss and improving supply efficiency.

Case Study 2: Gas Pipeline Maintenance in Bangladesh

In the construction of the JET-A1 underground pipeline from PITOLGANJ to KAD, mini repair clamps were used to address pressure-related pipeline failures. The corrosion-resistant properties of Conflex’s clamps ensured safety and reliability in transporting gas over long distances.

Why Choose Conflex Joints for Mini Repair Clamps?

About Conflex Joints

For over 15 years, Conflex Joints has been a leader in the design and manufacture of pipeline connection and repair products. Based in Yingkou, Liaoning Province, China, Conflex serves clients across the globe with a focus on innovation, quality, and customer satisfaction.

Key Features of Conflex Mini Repair Clamps

1. Custom Designs for Unique Needs

Conflex offers custom-built mini repair clamps to cater to specific pipeline requirements, ensuring a perfect fit for your infrastructure.

2. High-Quality Materials

- Steel Plate: SS304 for durability and strength.

- Rubber Gasket: NBR for excellent sealing properties.

- Bolt and Nut: Galvanized steel for corrosion resistance.

3. Pressure and Temperature Ratings

Conflex’s mini repair clamps operate under pressures of PN10/PN16 and temperatures ranging from -10°C to +70°C, making them suitable for diverse environmental conditions.

Services That Set Conflex Apart

Conflex provides end-to-end support, including:

- Pre-sales technical consultations: Helping you choose the right product.

- Installation guidance training: Ensuring correct and efficient use of repair clamps.

- After-sales services: Addressing any post-installation concerns promptly.

The Future of Pipeline Maintenance

As infrastructure investments grow globally, tools like mini repair clamps are becoming indispensable for efficient pipeline management. According to the Global Infrastructure Hub, global infrastructure spending will reach $94 trillion by 2040, creating enormous demand for innovative maintenance solutions like Conflex’s mini repair clamps.

Conclusion: Small Size, Big Impact

Mini repair clamps may be small, but their impact on pipeline maintenance is monumental. From their time-saving installation to their cost-effective and sustainable design, these clamps are a must-have for any industry reliant on pipeline infrastructure.

For businesses seeking reliable and high-quality solutions, Conflex Joints stands out as a trusted partner. With their robust mini repair clamps, industry expertise, and exceptional customer support, Conflex ensures that your pipeline operations are seamless and efficient.

Take the first step toward smarter pipeline management. Contact Conflex Joints today to explore their mini repair clamps and other innovative pipeline solutions.