PVC coupling installation of PVC pipe connection is most important in developing a secure and long-lasting plumbing system. Either you are a professional or a homeowner DIY, but the workmanship in PVC coupling installation gives a leak-tight and secure connection. Here in this tutorial, we will walk you step-by-step through what PVC couplings are, installation, issues you may experience, and how to maintain them in good condition so that you can achieve professional-quality finishes.

What is a PVC Coupling?

Why do we use a PVC Coupling?

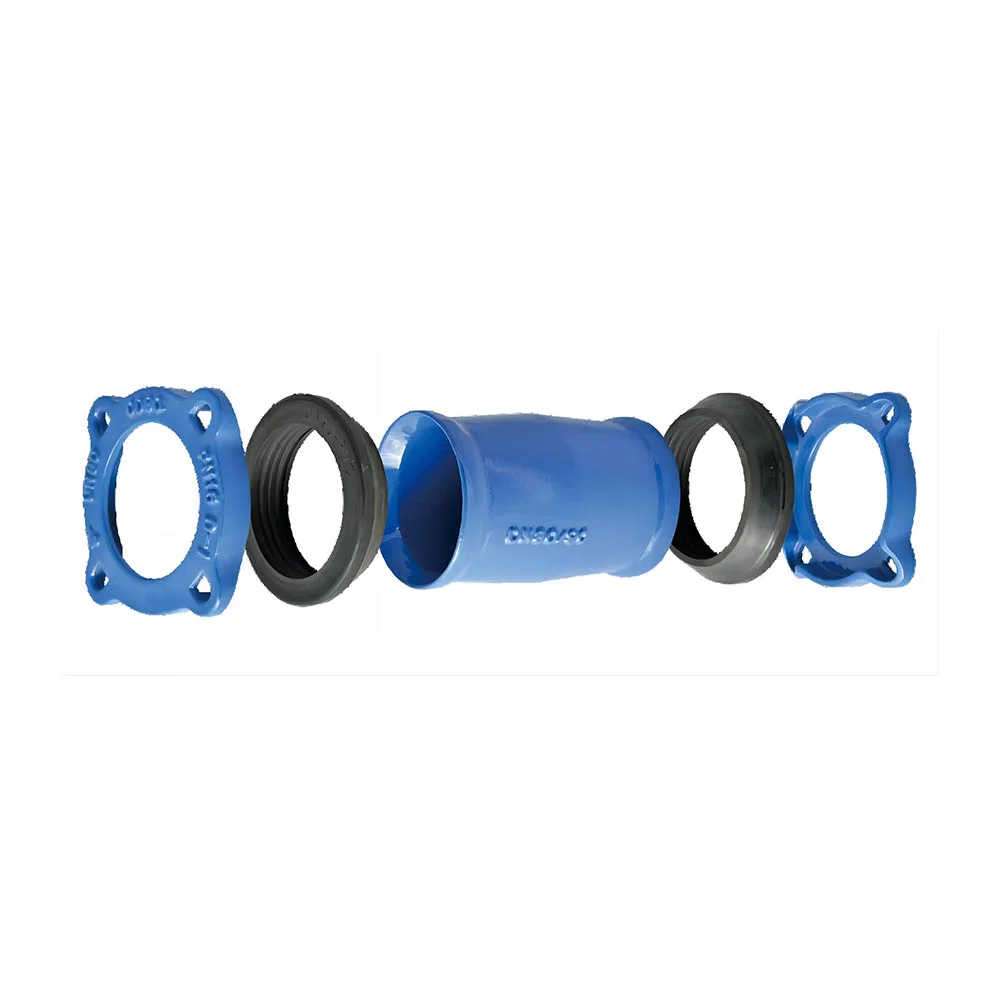

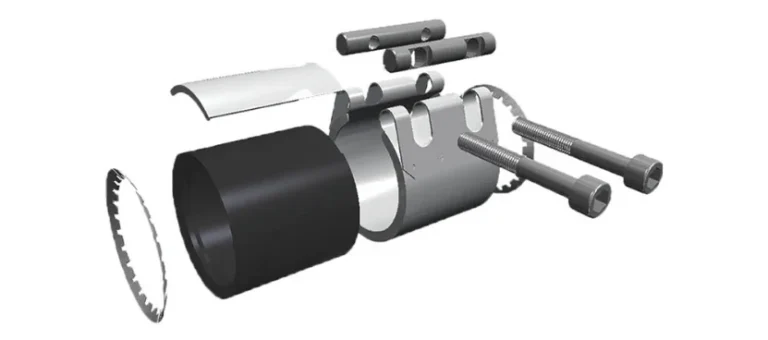

A PVC coupling is a pipe connector used in joining two segments of PVC pipe to create a single water-tight plumbing system. It may be internally grooved in such a way that the PVC pipes of certain diameters can be plugged into one side of the coupling. The connectors come in varying sizes so that they will fit different pipe diameters and therefore appropriate for a variety of uses in plumbing.

How Are PVC Couplings Made?

PVC couplings are made to be durable, easy to install, and resistant to weathering. They form an everlasting, watertight pipe-to-pipe joint, and are widely employed in drain systems, water supply systems, and sewer systems.

What Tools and Materials Do You Require to Fit PVC Coupling?

What Tools Do You Require to Fit PVC Couplings?

While working with PVC couplings is straightforward, you’ll need some basic tools to ensure precise cuts and proper installation. Here’s a list of what you’ll need:

- Pipe cutter or saw to cut PVC pipes to the correct length

- Measuring tape to measure the length of pipe and ensure an accurate fit

- Marker to mark where cuts should be made

- Deburring tool (if needed) to remove rough edges after cutting

- PVC primer and PVC cement to secure the pipes tightly to the coupling

- Gloves so that your hands do not come in contact with chemical substances like cement and primer

Always read the manual of the manufacturer first before starting to ensure proper installation and compatibility.

How to Join PVC Pipe and Couplings?

Step-by-Step Joining of PVC Pipe to Couplings

- Measure and Cut the Pipe: Measure the installed PVC pipe and mark where it will have to be cut. Square cut the pipe with a pipe cutter. Put the pipe tightly into the coupling to the groove.

- Deburr the Pipe:In case you’re not cutting the pipe with a pipe cutter, check the end of the cut for burs or dirt and remove them to ensure there’s a smooth connection.

- Dry Fit the Pipes:Dry-fit the pipe with the coupling before putting any primer or cement on it so that it will be the correct fit. This prevents errors after cementing.

- Use PVC Primer:Once you are happy with the fit, apply PVC primer to the exterior of the pipe and interior of the coupling. Allow it to stand for a minute to harden.

- Use PVC Cement:Use PVC cement on the areas that require it—the pipe and the coupling—once the primer is dry.

- Insert the Pipe:Insert the pipe into the coupling and rotate it a quarter so that the coupling and pipe will have a good union.

- Hold the Join: Hold the join for about 30 seconds to allow the cement to begin hardening. The join will set in 30 seconds, but allow it to set for at least 30 minutes before pressurizing or water testing.

How Do I Succeed in Joining a PVC Coupling

Best Most Tricks to a Strong Leak-Free PVC Join

Though joining PVC coupling is simple, there are certain steps that will make your joining effective and last long: Dry-fit the pipe: Dry-fit the pipe in the coupling initially for a close fit prior to cementing and priming.

- Debur the edges: Make sure the ends of the pipe are not rough because they will not seal.

- Use liberal primer and cement: Don’t be frugal with the primer or cement—liberal use is the key to a good, leak-free connection.

- Work fast: PVC cement will set very fast, so apply it and work fast to make the connection before the cement hardens.

By following these instructions to the last detail, you’ll have in your hands a safe and trustworthy PVC connection that will work perfectly well for years to come.

What are Common PVC Coupling Connection Problems and Their Solution?

Why do PVC Connectors Leak?

There are a number of reasons why PVC connections leak, the most frequent one being improper installation:

- Pipe misalignment: It will never seal if it is not properly aligned into the coupling or in the wrong direction and it will leak.

- Wrong primer or cement:If enough primer and cement are not placed on the pipe and on the coupling, then it will not bond in the right way and leak.

- Incorrect insertion at improper depth:The pipe must be inserted completely inside the coupling, into the groove. Otherwise, the joint leaks or fails.

How to avoid PVC Coupling failure?

Ensure that the pipe is seated firmly inside the coupling and the groove.

Primer and cement application: Correct primer and cement application to the pipe and within the coupling for a strong bond.

How Do You Store PVC Connectors?

What Type of Maintenance Does PVC Pipe Connector Need

PVC pipe fittings need minimal maintenance, yet occasional inspection will make them longer lasting and eliminate future problems:

- Avoid chemical buildup:Avoid letting dangerous chemicals, solvents, or oils migrate through PVC pipes since they will degrade the material over time.

- Avoid overpressure:Avoid subjecting the system to pressure above the pipe’s rated capacity.

Looking for Reliable Pipeline Connection Solutions?

In case you are searching for quality PVC couplings as well as other pipeline connecting fittings, Conflex Joints is a highly reputed company in the market. Conflex Joints has over 15 years of experience providing various types of pipeline solutions, such as:

- Flange Adaptors

- PVC pipe couplings

- Dismantling Joints

- Saddle Clamps

- Repair Clamps

- Flexible Connections

Conflex Joints provides cost-effective, quick, and efficient solutions for pipework and plumbing installations. Its WRAS-approved products are safe for drinking water and are made for simple installation, servicing, and maintenance. With its expert R&D team and knowledge, Conflex Joints can assist your piping needs while maintaining system reliability and stock costs to the lowest possible level.