In the world of piping systems, the efficiency, longevity, and reliability of pipe connections are critical to maintaining smooth operations across various industries, from water supply and gas to oil and chemicals.Most businesses are usually puzzled when it comes to selecting either of the options between universal pipe couplings or traditional pipe fittings. Which one would offer the most value, performance, and usability for specific needs? Comparisons between universal pipe couplings and traditional fittings are considered in the course of this article, their practical advantages and challenges put to the fore, and reasons why many industries are turning their focus to universal couplings highlighted.

What Are Universal Pipe Couplings?

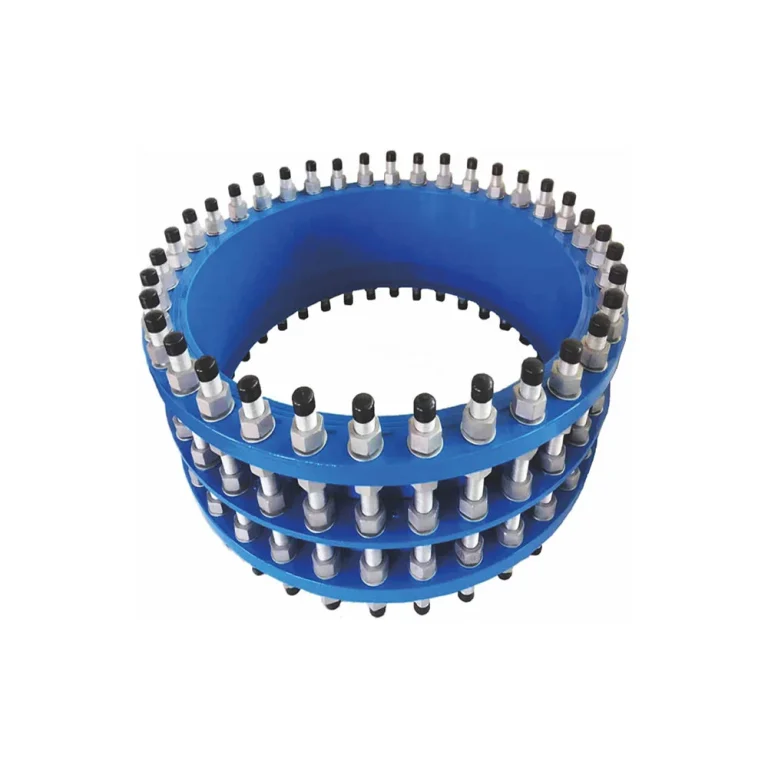

The mechanically fitted connectors join pipes made of different materials and sizes. Due to the advantage of handling variable pipe sizes, besides the materials involved in such couplings, like ductile iron, PVC, and stainless steel, they find a very broad application field in water, gas, and wastewater systems. Universal couplings allow for outstanding flexibility, especially in systems that require frequent adjustments or maintenance.

These couplings are designed to handle the high pipe movements resulting from subsidence, thermal expansion, and other frequent industrial piping system challenges. Among the major benefits of universal couplings is their allowance for connecting pipes made of different materials, thus offering an effective solution in systems where pipe material transitions are inevitable. The Conflex Joints Universal Coupling DN50-DN400 and DN50-DN300 enable fast, efficient installations, minimizing downtime and increasing operational continuity.

Traditional Fittings: The Old Guard of Piping Systems

Traditional pipe fittings include, but are not limited to, flanges, elbows, tees, and threaded connections, conventionally the backbone in the industry of piping. These types of fittings are usually used to connect pipes made of the same material and of the same size. They are available in various designs for different applications, including pressure-rated, corrosion-resistant, and high-temperature environments. Many traditional fittings require skilled labor operations, such as welding, threading, or flange bolting, which can be very time-consuming.

While traditional fittings work well for most applications, they tend to be less flexible than modern universal couplings. One of the major drawbacks with traditional systems is the need for special fittings when the material or size of the pipes varies. This can be costly and may involve lengthy installation processes.

Key Differences Between Universal Couplings and Traditional Fittings

Installation Speed and Ease

Speed and ease of installation: This, amongst many others, is one of the single most salient advantages universal couplings have over traditional fittings. The Conflex Joints Universal Coupling is designed for quick installation with a minimum amount of tooling and time. Instead of conventional methods requiring welding, threading, or bolting of flanges together, which takes much time, installation can be accomplished in a fraction of that time.

As one example, the universal couplings in Conflex Joints allow for a telescopic adjustment for various pipe lengths and a range of 5-10mm that facilitates ease of fit when the pipes are slightly out of alignment. By contrast, traditional fittings require precision alignment of parts, which leads to slower installation and, hence, increased labor costs.

In those industries where any kind of downtime means lost productivity or revenue, the ability to install universal couplings in record time is a big plus.

Flexibility and Adaptability

The design of universal couplings is pretty versatile, connecting pipes made of different materials and diameters. Therefore, in projects that call for joining different types of pipes, the usefulness of this coupling becomes evident. This, again, constitutes an explicit advantage compared to classic fittings, which are mostly material-specific or dependent on sizes.

For instance, Conflex Joints Universal Couplings can connect pipes made of ductile iron, steel, PVC, PE, stainless steel, and AC. The possibility of connecting different types of pipe materials without the use of special adapters makes universal couplings the staple for industries dependent on various piping materials, such as water treatment plants, gas stations, and wastewater management systems.

On the other hand, traditional fittings usually require custom solutions at transitions between dissimilar pipe materials, increasing the complexity and cost.

Durability and Long-Term Performance

In particular, universal couplings from leading manufacturers, such as Conflex Joints, are engineered to last. They handle very large pipe movements due to ground subsidence and other factors without losing their integrity. Universal couplings, with their corrosion-resistant materials and a mechanical locking mechanism, represent a more robust solution for systems operating in harsh environments.

The Conflex Joints Universal Coupling DN50-DN400 is manufactured to resist working pressures of PN10/PN16, withstand maximum temperatures from -10°C to +70°C, and therefore find perfect applications in general industrial and municipal fields. Besides, these couplings enjoy a reputation for being reliable and are certified by international organizations such as SGS and BV.

Traditional fittings, while reliable in their own right in certain contexts, often lack the flexibility and performance of modern universal couplings. In industries that involve extreme pressure or temperature fluctuations, traditional fittings may need additional reinforcements or specialized maintenance.

Cost Efficiency

Traditional fittings seem much cheaper initially but tend to have higher costs over time. This is because of the amount of material involved in the labor and mostly in dealing with complicated pipe systems, where custom-designed fittings are always needed.

On the other hand, universal couplings, an example of which is the Conflex Joints Universal Coupling, can save more money on a long-term basis. For one, the universality of their application means that no custom parts are needed for any given application, thus cutting down on overall material costs. In addition to that, much faster installation and reduced maintenance lower labor costs drastically.

Conformity to Industrial Standards

Universal couplings, like those produced by Conflex Joints, are certified against international industry standards and, as such, are acceptable in sensitive applications including potable water systems. The company’s products are certified to the WRAS standard to ensure their safety for use with drinking water. This level of certification and compliance affords peace of mind to enterprises in regulated businesses, such as municipal water suppliers and healthcare facilities.

On the other hand, traditional fittings may not always meet the specific regulatory requirements required for such applications. Compliance with local and international regulations sometimes requires additional documentation and certification processes, which can delay project timelines and increase costs.

Why Choose Conflex Joints Universal Pipe Couplings?

Within a very short period, Conflex Joints has emerged as one of the leading producers of high-quality industrial pipeline connections and repair products. With over 15 years of experience in this field, Conflex Joints offers a wide range of products to meet the requirements of different engineering companies.

Their Universal Pipe Couplings come in DN50-DN400 and DN50-DN300 sizes, manufactured from corrosion-resistant materials that ensure long life with reliable performance. These couplings can be applied to water supply systems, wastewater treatment, and gas pipelines.

Probably the most impressive feature of Conflex Joints Universal Couplings is that they can accommodate a wide range of pipe diameters and materials, making them highly versatile. The couplings also feature mechanical locking and telescopic adjustment, offering flexibility in installation and handling significant pipe movements.

Why It Matters to Businesses

Access to sound and compliant piping solutions has been a big plus for such industries as construction, water treatment, and gas distribution, to name a few. Conflex Joints is focused on offering quality and efficiency in the products, speed in installation and maintenance processes, and peace of mind in international standards.

Conclusion

While traditional pipe fittings have served industries for several decades, greater flexibility, quicker installation, and durability have made many companies move to universal couplings. With features like quick installation, flexibility for pipes of different materials, and according to industrial standards, the universal coupling often just turns out to be the better choice for modern piping systems.