1. What are Universal Pipe Couplings

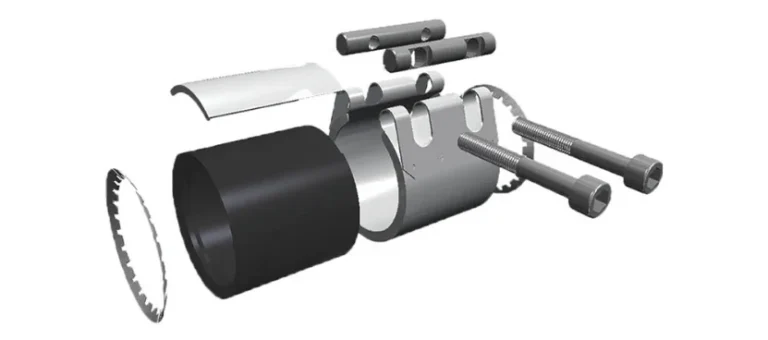

A universal pipe coupling is that versatile mechanical joint connecting pipes of different materials and diameters. Unlike traditional couplings, which may be used only with specific types of piping, a universal pipe coupling offers flexible options toward the joining of different types of piping and hence finds its use in a wide variety of pipeline systems. These couplings are designed to provide a reliable, leak-proof seal, yet allow some degree of movement and misalignment between the pipes. A general design of a universal pipe coupling consists of a sleeve, a rubber gasket, gland flanges, and bolts and nuts.

2. Key Applications of Universal Pipe Couplings

2.1. Connecting Dissimilar Pipes

One of the major uses of a universal pipe coupling is in the connection of pipes made from different materials. For example, such couplings can be used to connect ductile iron pipes to steel pipes or PVC pipes. This capability is particularly useful in situations where existing pipeline systems are made of various materials, or during upgrades and expansions when new materials are introduced. This makes the universal pipe coupling highly adaptable for many plumbing and industrial applications.

2.2. Facilitating Pipe Repairs

Universal pipe couplings are also indispensable in the repair of damaged sections of pipelines. Since they connect different types of pipes, this makes them very suitable for just replacing the damaged section without needing to replace the whole line with a certain type of pipe. Their easy installation design enables repairs to be very fast and efficient. This makes the universal pipe coupling a critical component for maintenance teams who have to address leaks and pipe failures in record time.

2.3. Simplifying Installation of Valves and Fittings

These couplings allow for easier fittings of valves, flange pipes, and others. They are flexible couplings that make it easier to align and connect these parts, thereby reducing the time and difficulty with which these could be installed. That is the reason why the universal pipe couplings are heavily used with pumps and other apparatuses in supplying water and draining systems to provide easy access to the whole plumbing infrastructure.

2.4 Accommodating Pipeline Movement

Universal pipe couplings allow for some degree of angular deflection and pipeline movement. This is critical in preventing damage due to thermal expansion, ground movement, or other factors that might cause stress on rigid pipe systems. This flexibility is also important in reducing the risk of leaks and pipe damage. The ability of a universal pipe coupling to handle these dynamic shifts adds to the overall reliability and longevity of a piping system.

3. Benefits of a Universal Pipe Coupler

3.1. Reduced Inventory Costs

A universal pipe coupling being accommodating for a wide range of materials and sizes in its connection, reduces the many types of couplings that are kept in stock. This capability for handling different types of pipes reduces the inventory costs and simplifies the logistics for distributors. The versatility helps the companies ease into streamlining their operations and reducing storage space.

3.2. Ease of Installation and Repair

A universal pipe coupling is made in a way that it can easily be installed by the use of ordinary tools such as spanners without undergoing specialized training in labor. Besides, their design simplicity allows it to be dismantled and assembled easily for maintenance purposes, hence suitable for rapid repairs. All these simplicities in its installation and repairs mean that it saves time, not only to the plumbers but also construction teams.

3.3. Adaptability and Flexibility

The universal pipe coupling is designed to adapt to a wide range of applications. Because of their flexibility, they are suitable for many uses, ranging from potable water and recycled water to sewage and even some industrial applications. That makes the universal pipe coupling adaptable to a variety of piping requirements.

3.4. Durability and Corrosion Resistance

Universal pipe couplings are typically made from ductile iron or steel, with a premium coating of epoxy resin. This will have them work under harsh conditions, making them strong and resistant to corrosion for the maintenance of pipeline integrity. This durability enables a universal pipe coupling to be reliable for an extended period, reducing frequency in replacements.

4. Types of Pipes Compatible with Universal Pipe Couplings

4.1. Ductile Iron Pipes

The universal pipe couplings are widely used to connect the ductile iron pipes. This gives them strength in the joint and is reliable. Since ductile iron pipes are strong, their joints will be complemented by these couplers, which securely connect them.

4.2. Steel Pipes

These couplings are also suitable for joining steel pipes, offering a wide range of possibilities in industrial and commercial piping systems. For this purpose, steel pipes need strong joints, and the universal pipe coupling offers them secure connections that can bear high pressures and temperatures.

4.3. PVC Pipes

Universal pipe couplings find a very broad field of application in PVC pipes for connecting the pipes in water supply and drainage systems. Due to their light weight, the working of PVC pipes is easy, while these couplings add to their workability by offering fast, dependable jointing options.

4.4. Other Pipe Materials

Besides the above, universal pipe couplings can also be connected to GRP pipes (Glass Reinforced Plastic) and AC pipes (Asbestos Cement). This really makes the universal pipe coupling very versatile in construction and repair, where different pipe materials are frequently dealt with.

4. Key Features of a High-Quality Universal Pipe Coupling

5.1. Material Composition and Standards

Universal pipe couplings shall be manufactured from the best ductile iron or steel with some protective coating, typically a fusion bond epoxy. It should be in accordance with the relevant industrial standard. GGG50 ductile iron and steel conforming to EN 1563 and EN 10025 correspondingly may be used. Such materials will ensure that the couplings are strong and resistant to rust.

5.2. Gasket Hardness

Hardness of the gasket is another most important issue related to the performance of the gasket in achieving a good seal. A common gasket made for normal purposes has a Brinell hardness of about 65 BHN. The proper hardness is just right so that the gasket will deform with pressure in view to effect a tight seal but still hang together. For some applications, where gaps are larger or pressure is higher, harder gaskets may be required to prevent being pushed out of the seal position.

5.3. Working Pressure and Temperature Ranges

Universal pipe couplings should be able to resist the intended working pressures and temperatures. The working pressure ratings for a good-quality coupling will normally be PN10 or PN16, and the temperature resistance will range from -10°C to +70°C. These parameters ensure the reliability of the coupling in various environments.

5.4. Certifications

Couplings intended for potable water systems should have certifications such as WRAS approval, indicating that the materials used are safe to use with drinking water. These certifications assure that the product meets the required standards of safety and quality.

6. Selection of the Proper Universal Pipe Coupling

In selecting the correct universal pipe coupling, several factors need to be considered:

Pipe Material/Diameter: Ensure the coupling is compatible with the material and diameter of the pipes that you will be connecting.

Operating Conditions: Pick a coupling whose operating pressure and temperature range suit your system’s application.

Installation Needs: Ease of installation, special tools, or equipment required.

Certifications: Confirm that the coupling has the right certifications for the job, specifically if the systems will be dealing with potable water.

Quality and Brand: Choose good brands and suppliers with high standards in the manufacture for durability.

7.Conflex Joints and Universal Pipe Couplings

Conflex Joints are a well-established manufacturer of numerous pipeline connection and repair products. Among the many products the company offers is the universal pipe coupling. Having acquired over 15 years’ experience, Conflex Joints provides high quality products and swift services to many engineering companies throughout the world. Its product category has a huge list, comprising flange adaptors, couplings, dismantling joints, saddle clamps, repair clamps, flexible connections, etc.

Conflex aims to satisfy the needs of every customer with a view to becoming one of the leading providers in pipeline connection solutions in the world. Its products are for easy installation and fast repair; the main applications are water supply, drainage, heating, gas, oil, and chemical companies. They also cooperate with international testing agencies such as SGS and BV in ensuring that their products meet international standards. In order to learn and practice, technical support and after-sales service staff in the company visit the production base regularly to guarantee a better service for customers.