The product is used to connect PE pipe with metal pipe or valve, flowmeter, pressure gauge and other auxiliary equipment. The sealing method adopts socket type, and the dovetail groove design of sealing rubber ring has very good sealing performance, which can meet the sealing pressure of 2.5MPa at most.

Special design is allowable, welcome to contact us.

The product is used to connect PE pipe with metal pipe or valve, flowmeter, pressure gauge and other auxiliary equipment. The sealing method adopts socket type, and the dovetail groove design of sealing rubber ring has very good sealing performance, which can meet the sealing pressure of 2.5MPa at most.

Special design is allowable, welcome to contact us.

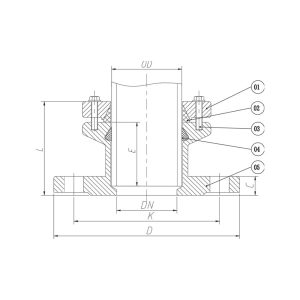

| Part No. | Part Name | Material | Standard |

| 1 | Flange Pipe | GGG50 | EN1563 |

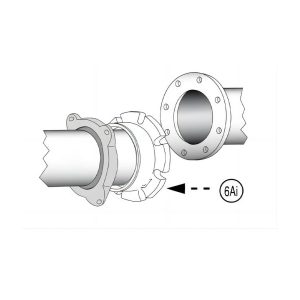

| 2 | Rubber Gasket | EPDM/SBR/NBR | ISO4633 |

| 3 | Gland Flange | GGG50 | EN1563 |

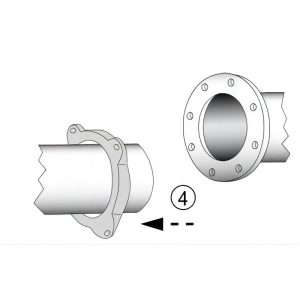

| 4 | Bolts&Nuts | Carbon Steel 6.8/8.8, SS, Dacromet | ISO898 |

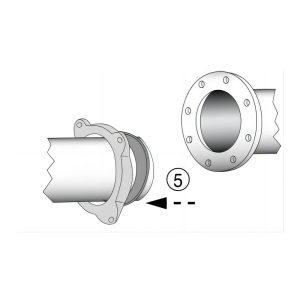

| 5 | Finish Layer | Fusion Bond Epoxy etc. | EN14901 |

| Briefs & Features | |

| 1 | Connection for HDPE pipe. |

| 2 | Working pressure PN10/PN16. |

| 3 | Maximum temperature -10°C to+70°C. |

| 4 | Suitable for potable water (WRAS approved), neutral liquids and sewage. Corrosion resistant structure. |

| Complying Standard | |

| Flange drilling | EN1092-2, EN1092-1, ANSI |

| Coating | EN30677 |

| Test | EN12266-1 |

|

Flange Adjustable Adaptor for PE pipe

| DN | øpipeA | øD | øK | C | L | E | Bolt | |

| Quantity | Thread | |||||||

| 50 | 63 | 165 | 125 | 19 | 90 | 80 | 4 | M16 |

| 60 | 63 | 175 | 135 | 19 | 90 | 80 | 4 | M16 |

| 60 | 75 | 175 | 135 | 19 | 92 | 82 | 4 | M16 |

| 65 | 63 | 185 | 145 | 19 | 90 | 80 | 4 | M16 |

| 65 | 75 | 185 | 145 | 19 | 92 | 82 | 4 | M16 |

| 80 | 63 | 200 | 160 | 19 | 90 | 80 | 8 | M16 |

| 80 | 75 | 200 | 160 | 19 | 92 | 82 | 8 | M16 |

| 80 | 90 | 200 | 160 | 19 | 95 | 85 | 8 | M16 |

| 100 | 90 | 220 | 180 | 19 | 95 | 85 | 8 | M16 |

| 100 | 110 | 220 | 180 | 19 | 95 | 85 | 8 | M16 |

| 100 | 125 | 220 | 180 | 19 | 97 | 87 | 8 | M16 |

| 125 | 110 | 250 | 210 | 19 | 95 | 85 | 8 | M16 |

| 125 | 125 | 250 | 210 | 19 | 97 | 87 | 8 | M16 |

| 125 | 140 | 250 | 210 | 19 | 103 | 93 | 8 | M16 |

| 125 | 160 | 250 | 210 | 19 | 145 | 110 | 8 | M16 |

| 150 | 140 | 285 | 240 | 19 | 103 | 93 | 8 | M20 |

| 150 | 160 | 285 | 240 | 19 | 115 | 105 | 8 | M20 |

| 150 | 180 | 285 | 240 | 19 | 125 | 115 | 8 | M20 |

| 200 | 200 | 340 | 295 | 20 | 135 | 125 | 8 | M20 |

| 200 | 225 | 340 | 295 | 20 | 138 | 128 | 8 | M20 |

| 200 | 250 | 340 | 295 | 20 | 225 | 145 | 8 | M20 |

| 250 | 250 | 400 | 350 | 22 | 155 | 145 | 12 | M20 |

| 250 | 280 | 400 | 350 | 22 | 158 | 148 | 12 | M20 |

| 300 | 315 | 455 | 400 | 25 | 184 | 174 | 12 | M20 |

| 300 | 355 | 455 | 400 | 25 | 277 | 237 | 12 | M20 |

| 400 | 400 | 565 | 515 | 25 | 242 | 230 | 16 | M24 |

| 400 | 450 | 565 | 515 | 25 | 302 | 260 | 16 | M24 |

| 500 | 500 | 715 | 620 | 32 | 365 | 346 | 20 | M24 |

| 500 | 560 | 715 | 620 | 32 | 450 | 372 | 20 | M24 |

| 600 | 630 | 840 | 725 | 36 | 459 | 399 | 20 | M27 |

|

|

|

|

|

|

|

|