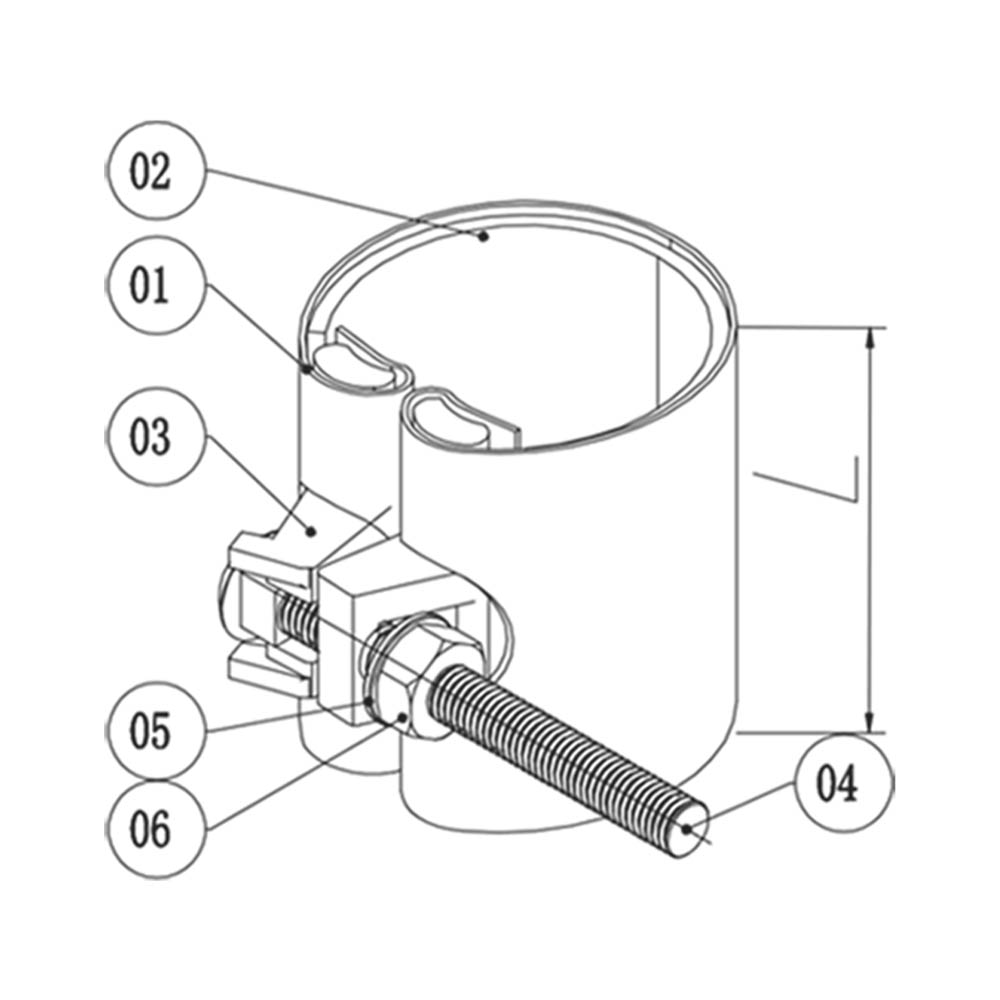

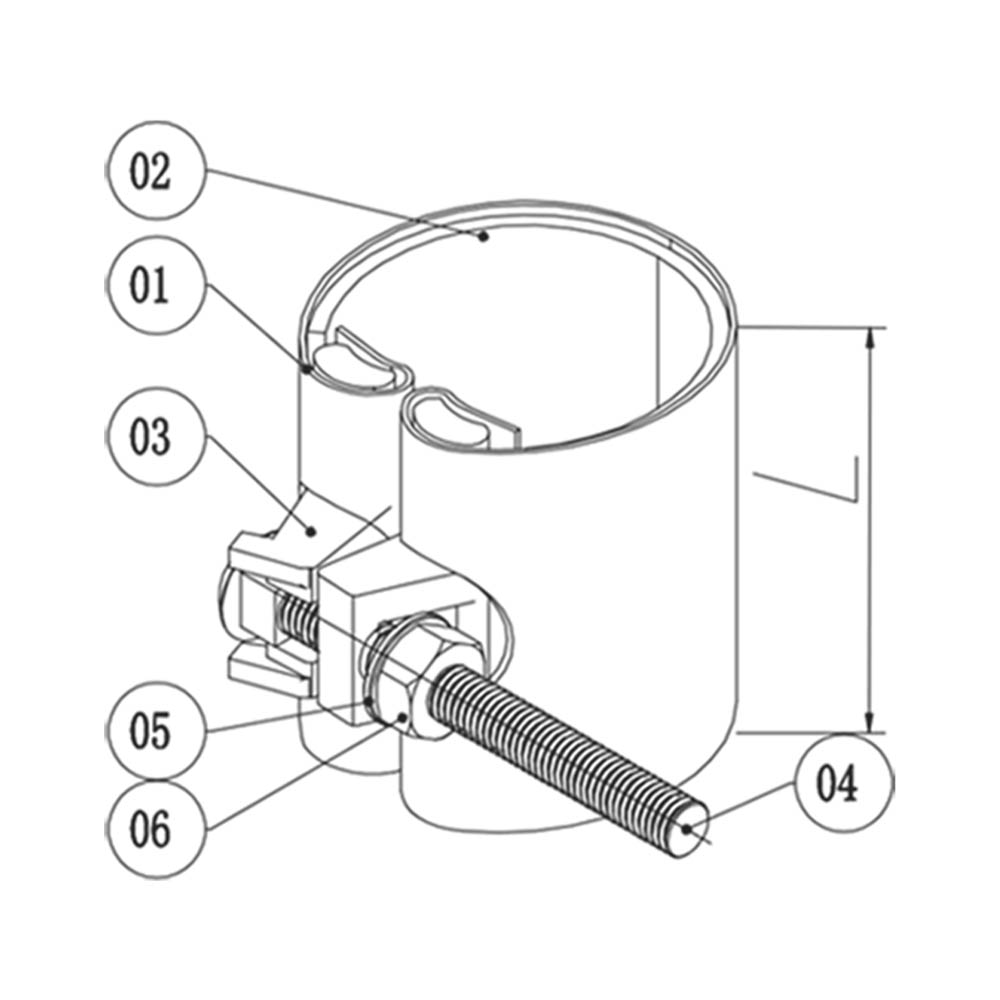

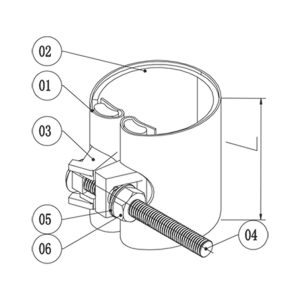

| Part No. | Part Name | Material | Standard |

| 1 | Steel Plate | SS304 | DIN17224 |

| 2 | Rubber Gasket | NBR | EN681-1 |

| 3 | Body | Ductile Iron | DIN10100-80 |

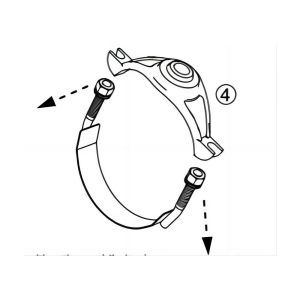

| 4 | Bolt | Galvanized steel 8.8 grade | DIN103-7 |

| 5 | Washer | Galvanized steel | DIN17224 |

| 6 | Nut | Galvanized steel | DIN17224 |

| Briefs & Features | |

| 1 | Suitable for maintenance of pipeline such as water, sewage, gas/natural gas supply, electricity, industrial production. |

| 2 | Working pressure PN10/PN16. |

| 3 | Maximum temperature -10°C to+70°C. |

| 4 | Suitable for potable water (WRAS approved), recycled water and sewage. Corrosion resistant structure. |

|

Lenght of screw(bolt)=M10×90mm

Gasket thickness=3.5mm

Band thickess=0.5mm

| DN | Inch | Scope | Pressure | Closing Torque |

| 15 | 1/2 | 19-23 | 1.6Mpa | 1.6Mpa |

| 20 | 3/4 | 24-28 | 1.6Mpa | 1.6Mpa |

| 25 | 1 | 29-34 | 1.6Mpa | 1.6Mpa |

| 32 | 11/4 | 38-42 | 1.6Mpa | 1.6Mpa |

| 40 | 11/2 | 44-48 | 1.6Mpa | 1.6Mpa |

| 50 | 2 | 55-61 | 1.6Mpa | 1.6Mpa |

| 65 | 21/2 | 69-73/71-76/76-82 | 1.6Mpa | 1.6Mpa |

| 80 | 3 | 82-87/87-93/94-100/99-104 | 1.6Mpa | 1.6Mpa |

| 100 | 4 | 105-111/112-118/120-126 | 1.6Mpa | 1.6Mpa |

| 125 | 5 | 126-131/132-138/140-146 | 1.6Mpa | 1.6Mpa |

|

|

|

|

|