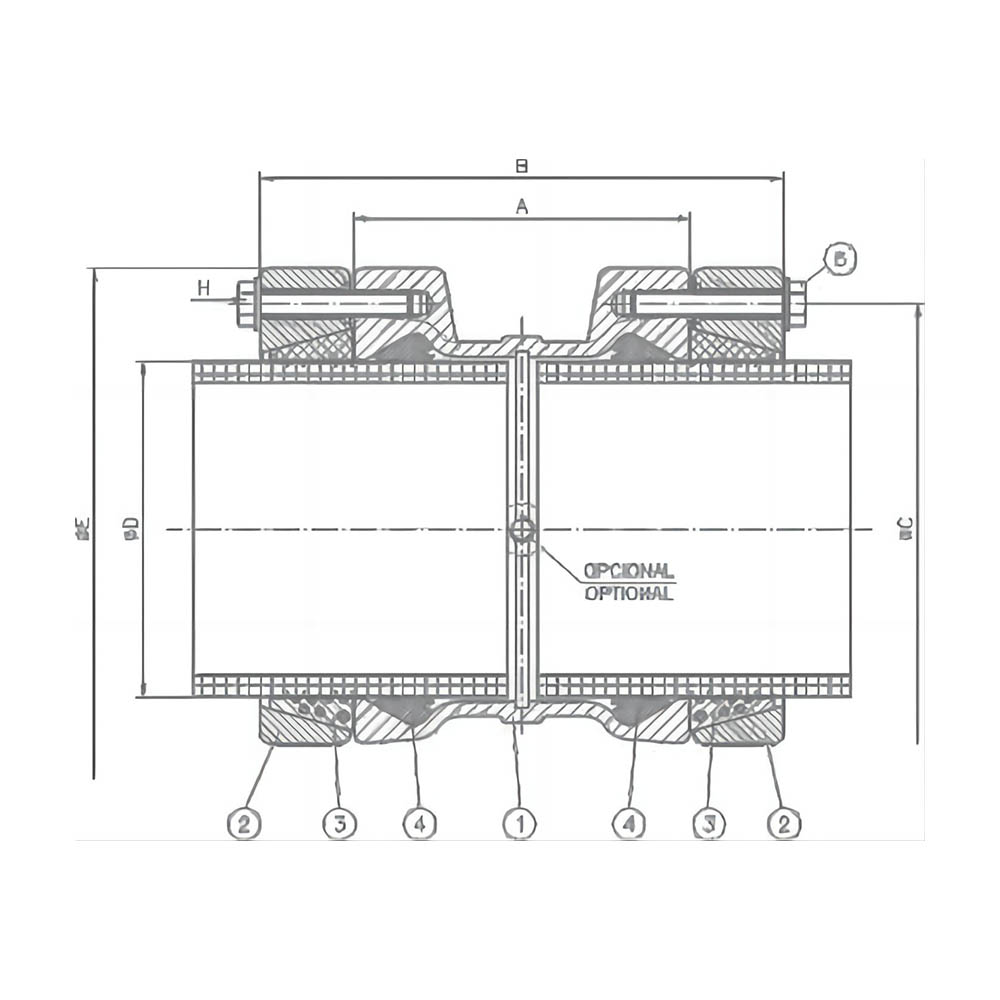

Coupling for PE pipe is suitable for pipeline, both end is socket. We use a new mechanical coupling technology to save the installation time.

Mechanical locking by means of metal inserts in order to avoid pipes axial movement, independant clamping on both sides.

Special design is allowable, welcome to contact us.

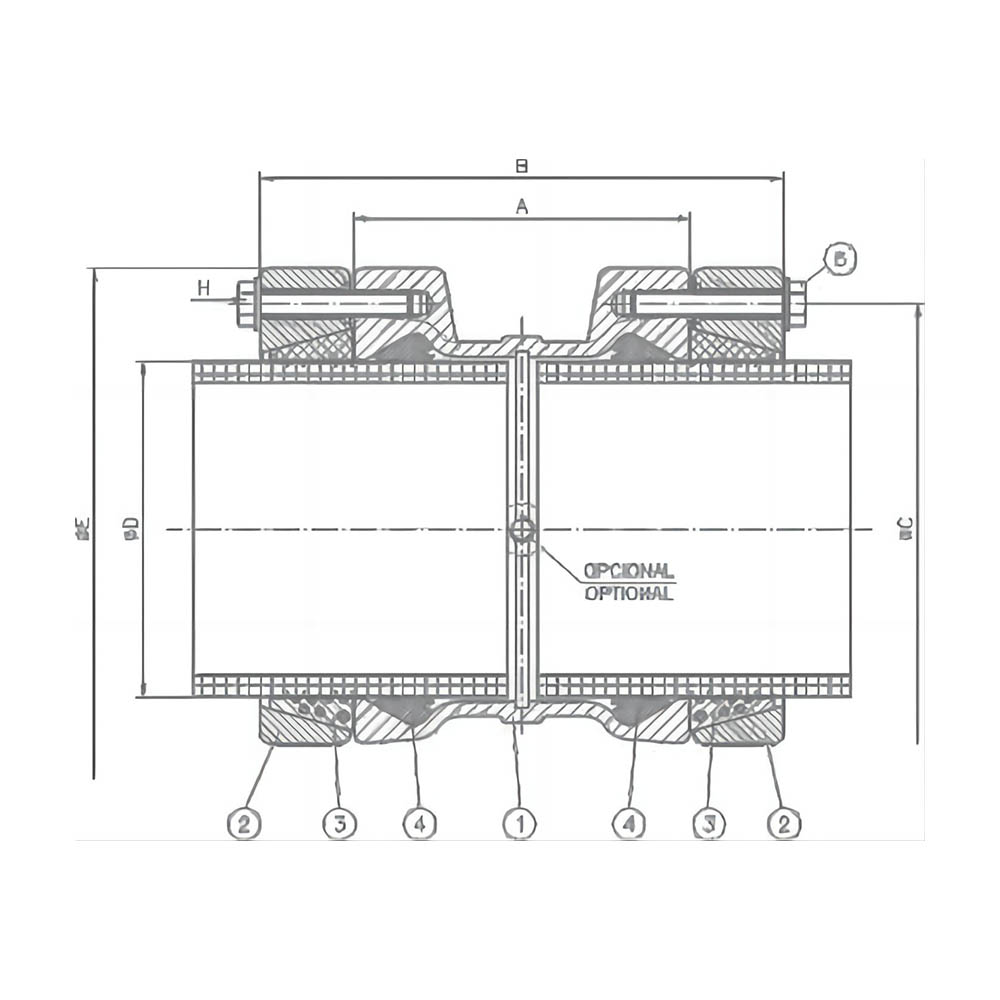

Coupling for PE pipe is suitable for pipeline, both end is socket. We use a new mechanical coupling technology to save the installation time.

Mechanical locking by means of metal inserts in order to avoid pipes axial movement, independant clamping on both sides.

Special design is allowable, welcome to contact us.

| Part No. | Part Name | Material | Standard |

| 1 | Flange Pipe | GGG50 | EN1563 |

| 2 | Rubber Ring | EPDM/SBR/NBR | ISO4633 |

| 3 | Gland Flange | GGG50 | EN1563 |

| 4 | Bolts&Nuts | Carbon Steel 4.8/8.8, SS, Dacromet | ISO898 |

| 5 | Finish Layer | Fusion Bond Epoxy etc. | EN14901 |

| Briefs & Features | |

| 1 | Suitable for PE pipes. |

| 2 | Working pressure PN10/PN16. |

| 3 | Maximum temperature -10°C to+70°C. |

| 4 | Suitable for potable water (WRAS approved), recycled water and sewage. Corrosion resistant structure. |

| 5 | Total angle deviation is +/- 6 degree. |

| Complying Standard | |

| Flange drilling | EN1092-2, EN1092-1, ANSI |

| Coating | EN30677 |

| Test | EN12266-1 |

|

| OD | A | B | C | E | H |

| 50 | 120 | 194 | 102 | 126 | 4-M10×60 |

| 63 | 120 | 194 | 105 | 129 | 4-M10×60 |

| 75 | 120 | 194 | 118 | 142 | 8-M10×60 |

| 90 | 130 | 204 | 133 | 157 | 8-M10×60 |

| 110 | 130 | 204 | 153 | 177 | 8-M10×60 |

| 125 | 135 | 210 | 168 | 192 | 8-M10×60 |

| 140 | 140 | 234 | 195 | 229 | 8-M12×75 |

| 160 | 160 | 254 | 215 | 249 | 8-M12×75 |

| 180 | 170 | 265 | 235 | 269 | 8-M12×75 |

| 200 | 190 | 285 | 255 | 289 | 12-M12×75 |

| 225 | 210 | 305 | 280 | 314 | 12-M12×75 |

| 250 | 230 | 325 | 305 | 339 | 12-M12×75 |

| 280 | 250 | 345 | 283 | 317 | 12-M12×75 |

| 315 | 270 | 365 | 373 | 407 | 12-M12×75 |