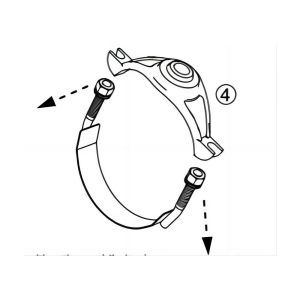

The main function of this product is to open a branch pipe or install the faucet or water meter in any part of the pipeline temporarily after the completion of the installation of the whole pipeline and already running. Quick removal of the product, the installation of only one wrench, torque wrench to tighten high-strength steel or stainless steel connection bolt is one of the most important features of the series.

Special design is allowable, welcome to contact us.

The main function of this product is to open a branch pipe or install the faucet or water meter in any part of the pipeline temporarily after the completion of the installation of the whole pipeline and already running. Quick removal of the product, the installation of only one wrench, torque wrench to tighten high-strength steel or stainless steel connection bolt is one of the most important features of the series.

Special design is allowable, welcome to contact us.

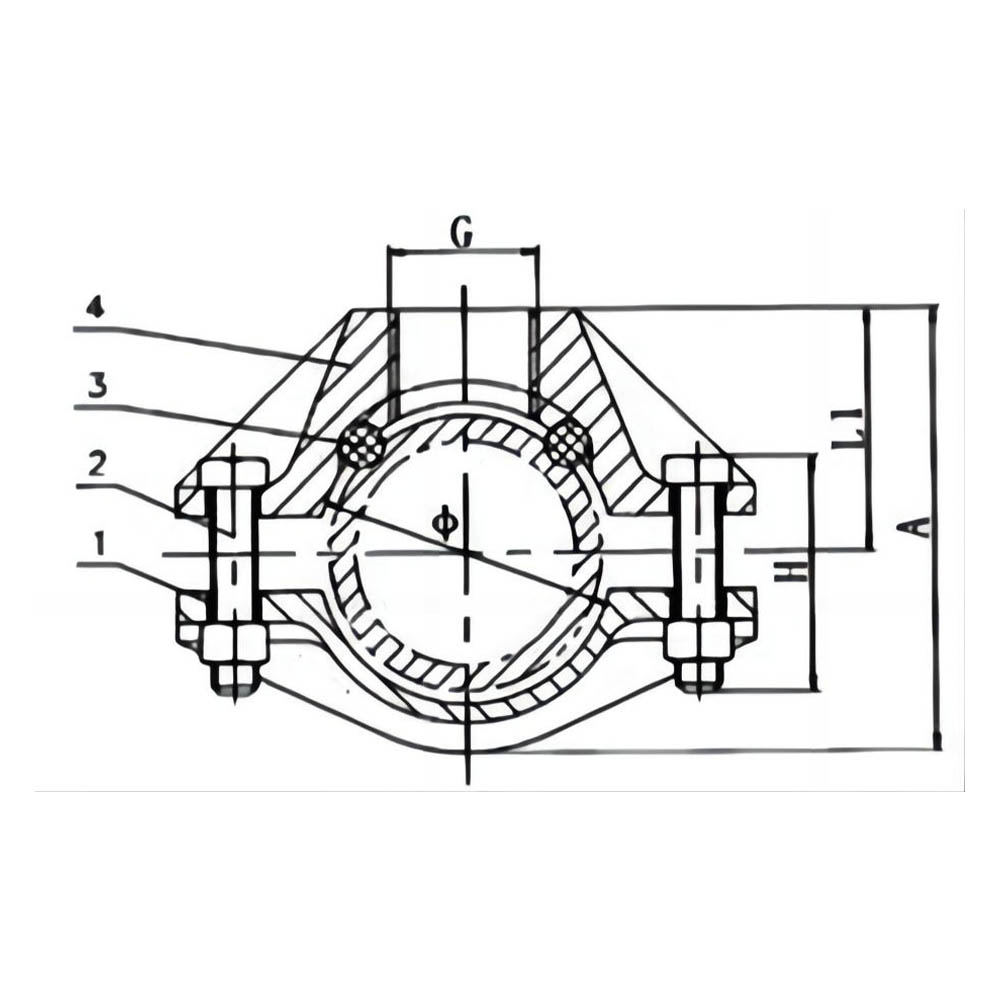

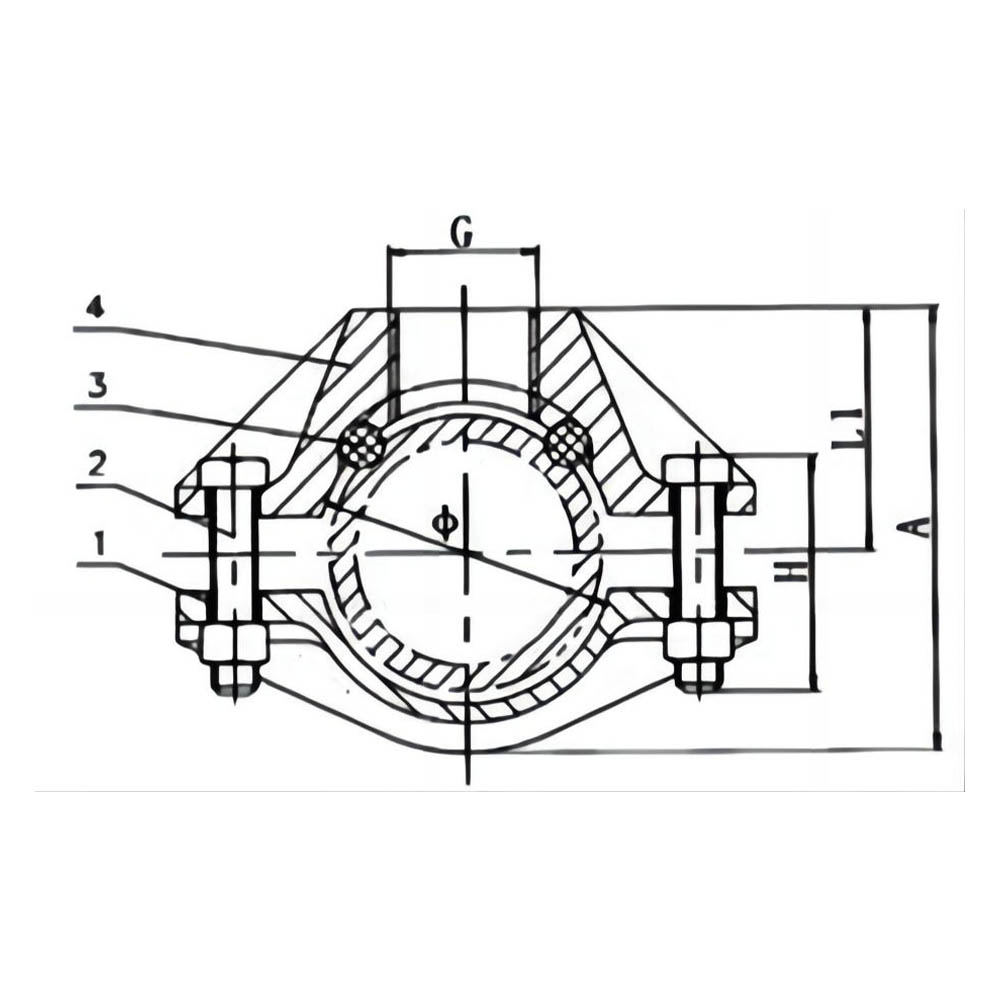

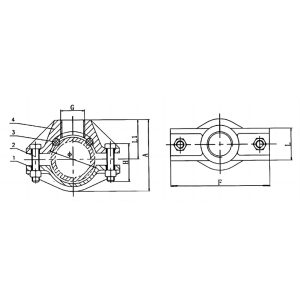

| Part No. | Part Name | Material | Standard |

| 1 | Body | GGG50 | EN1563 |

| 2 | Rubber Ring | EPDM/SBR/NBR | ISO4633 |

| 3 | Gland Flange | GGG50 | EN1563 |

| 4 | Bolts&Nuts | Carbon Steel 4.8/8.8, SS, Dacromet | ISO898 |

| 5 | Finish Layer | Fusion Bond Epoxy etc. | BS EN14901 |

| Briefs & Features | |

| 1 | Suitable for DI pipes. |

| 2 | Working pressure PN10/PN16. |

| 3 | Maximum temperature -10°C to+70°C. |

| 4 | Suitable for potable water (WRAS approved), recycled water and sewage. Corrosion resistant structure. |

| 5 | Total angle deviation is +/- 3 degree. |

| Complying Standard | |

| Flange drilling | EN1092-2, EN1092-1, ANSI |

| Coating | EN30677 |

| Test | EN12266-1 |

|

| Item | Specification(mm) | ||||||

| ∅ | F | G | L | A | L1 | H | |

| 60~3/4” | 60 | 155 | 3/4” | 80 | 118 | 65 | M12×90 |

| 60~1” | 1” | ||||||

| 60~1 1/4” | 1 1/4” | ||||||

| 60~1 1/2” | 1 1/2” | ||||||

| 80~1” | 80 | 175 | 1” | 80 | 138.5 | 75 | M12×90 |

| 80~1 1/4” | 1 1/4” | ||||||

| 80~1 1/2” | 1 1/2” | ||||||

| 100~1” | 100 | 195 | 1” | 92 | 165 | 91 | M12×90 |

| 100~1 1/4” | 1 1/4” | ||||||

| 100~1 1/2” | 1 1/2 ” | ||||||

| 100~2” | 2” | ||||||

| 125~1” | 125 | 220 | 1” | 92 | 193 | 104 | M12×90 |

| 125~1 1/4” | 1 1/4” | ||||||

| 125~1 1/2” | 1 1/2” | ||||||

| 125~2” | 2” | ||||||

| 150~1” | 150 | 245 | 1” | 92 | 209 | 107 | M12×100 |

| 150~1 1/4” | 1 1/4” | ||||||

| 150~1 1/2” | 1 1/2” | ||||||

| 150~2” | 2” | ||||||

| 175~1” | 175 | 260 | 1” | 92 | 243.5 | 129 | M12×130 |

| 175~1 1/4” | 1 1/4” | ||||||

| 175~1 1/2” | 1 1/2” | ||||||

| 175~2” | 2” | ||||||

| 200~1” | 200 | 276 | 1” | 122 | 276 | 143 | M12×140 |

| 200~1 1/4” | 1 1/4” | ||||||

| 200~1 1/2” | 1 1/2” | ||||||

| 200~2” | 2” | ||||||

| 250~1” | 250 | 330 | 1” | 122 | 333 | 174 | M12×160 |

| 250~1 1/4” | 1 1/4” | ||||||

| 250~1 1/2” | 1 1/2” | ||||||

| 250~2” | 2” | ||||||

| 300~1” | 300 | 380 | 1” | 122 | 385 | 200 | M12×180 |

| 300~1 1/4” | 1 1/4” | ||||||

| 300~1 1/2” | 1 1/2” | ||||||

| 300~2” | 2” | ||||||

|

|

|

|

|