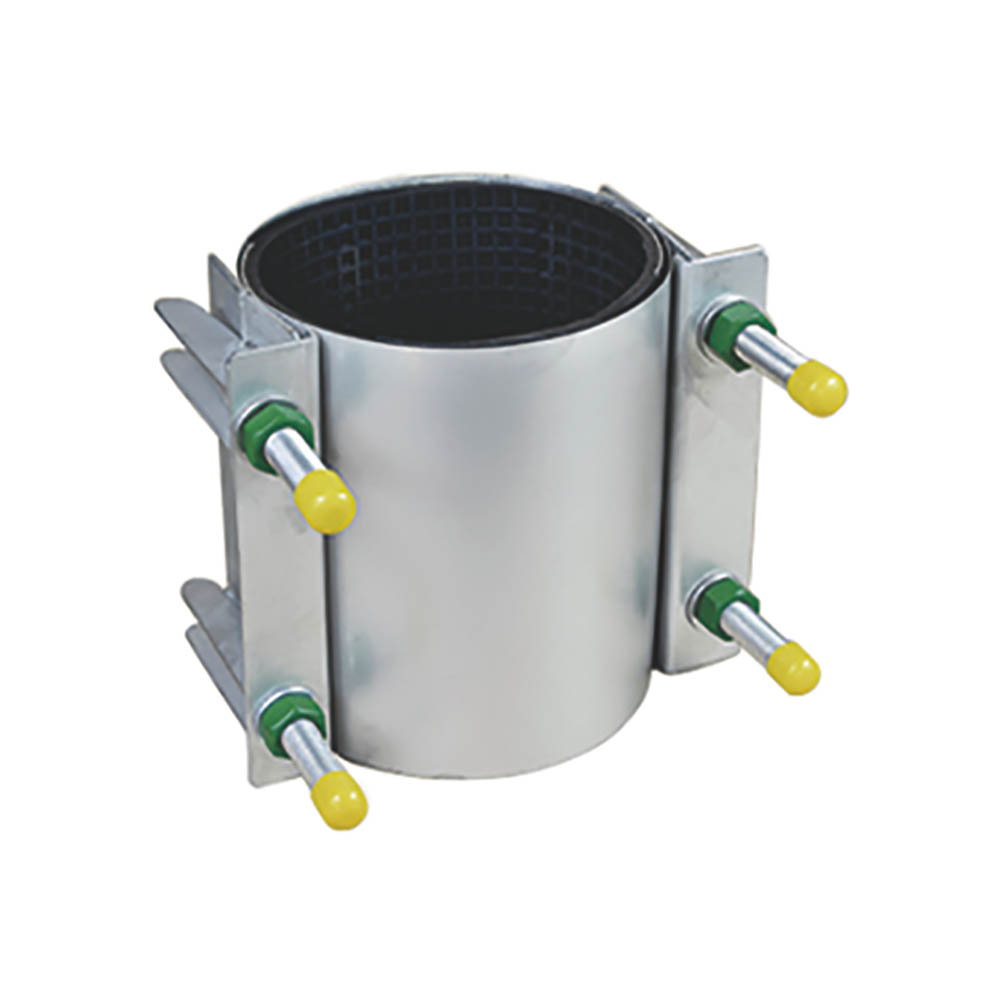

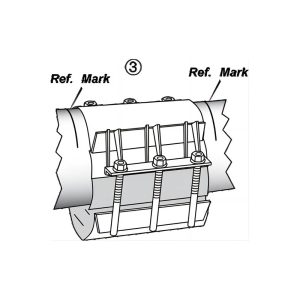

The stainless steel band repair clamp provides a quick and economic way to repair damages of different pipes, such as leakage, perforation, and longitudinal cracks. It can be installed on running pipelines.

Special design is allowable, welcome to contact us.

The stainless steel band repair clamp provides a quick and economic way to repair damages of different pipes, such as leakage, perforation, and longitudinal cracks. It can be installed on running pipelines.

Special design is allowable, welcome to contact us.

| Part No. | Part Name | Material | Standard |

| 1 | Steel Shell | SS304 | AS4181-2013 |

| 2 | Rubber Sheet | EPDM | ISO4633 |

| 3/4/5 | Fastener | SS304 | AS4181-2013 |

| 6 | Gusset Plate | SS304 | AS4181-2013 |

| 7 | Guide Plate | SS304 | AS4181-2013 |

| 8 | Support Plate | SS304 | AS4181-2013 |

| 9 | Claw | SS304/Cast Iron | AS4181-2013/EN1563 |

| Briefs & Features | |

| 1 | Suitable for maintenance of pipeline such as water, sewage, gas/natural gas supply, electricity, industrial production. |

| 2 | Working pressure PN10/PN16. |

| 3 | Maximum temperature -10°C to+70°C. |

| 4 | Suitable for potable water (WRAS approved), recycled water and sewage. Corrosion resistant structure. |

|

|

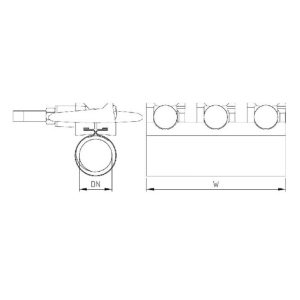

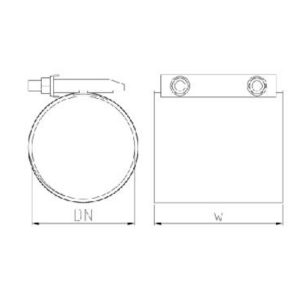

| CR/ZR-1 | PN | CR/ZR-2 | PN | CR/ZR-3 | PN | CR/ZR-4 | PN | W |

| 59-67 | 16 | 150-600 | ||||||

| 65-73 | 16 | 150-600 | ||||||

| 69-76 | 16 | 150-600 | ||||||

| 75-83 | 16 | 150-600 | ||||||

| 86-94 | 16 | 88-108 | 16 | 150-600 | ||||

| 108-118 | 16 | 108-128 | 16 | 150-2000 | ||||

| 113-121 | 16 | 13-133 | 16 | 150-2000 | ||||

| 121-131 | 16 | 120-141 | 16 | 150-2000 | ||||

| 126-136 | 16 | 168-188 | 16 | 150-2000 | ||||

| 132-142 | 16 | 174-194 | 16 | 150-2000 | ||||

| 145-155 | 16 | 219-239 | 16 | 150-2000 | ||||

| 151-161 | 16 | 228-249 | 16 | 150-2000 | ||||

| 159-170 | 16 | 238-258 | 16 | 150-2000 | ||||

| 166-177 | 16 | 258-278 | 16 | 150-2000 | ||||

| 170-180 | 16 | 273-293 | 10 | 150-2000 | ||||

| 174-184 | 16 | 282-302 | 10 | 150-2000 | ||||

| 179-189 | 16 | 295-315 | 10 | 150-2000 | ||||

| 189-199 | 16 | 324-344 | 10 | 150-2000 | ||||

| 218-228 | 16 | 335-356 | 10 | 150-2000 | ||||

| 222-233 | 16 | 347-367 | 10 | 150-2000 | ||||

| 229-239 | 16 | 357-376 | 10 | 150-2000 | ||||

| 236-246 | 16 | 365-384 | 10 | 150-2000 | ||||

| 248-258 | 16 | 383-402 | 10 | 150-2000 | ||||

| 250-260 | 10 | 404-423 | 10 | 150-2000 | ||||

| 252-263 | 10 | 421-440 | 10 | 150-2000 | ||||

| 261-271 | 10 | 436-455 | 10 | 150-2000 | ||||

| 271-281 | 10 | 453-472 | 10 | 150-2000 | ||||

| 280-291 | 10 | 469-488 | 10 | 150-2000 | ||||

| 288-298 | 10 | 488-507 | 10 | 150-2000 | ||||

| 298-309 | 10 | 505-525 | 10 | 150-2000 | ||||

| 300-310 | 10 | 526-545 | 8 | 150-2000 | ||||

| 304-314 | 10 | 547-566 | 8 | 150-2000 | ||||

| 321-331 | 10 | 562-581 | 8 | 630-660 | 8 | 150-2000 | ||

| 333-343 | 10 | 582-601 | 8 | 670-700 | 8 | 150-2000 | ||

| 340-351 | 10 | 630-650 | 8 | 720-750 | 8 | 150-2000 | ||

| 348-358 | 10 | 670-690 | 8 | 770-800 | 6 | 150-2000 | ||

| 356-366 | 10 | 720-740 | 8 | 820-850 | 6 | 150-2000 | ||

| 870-900 | 6 | 150-2000 | ||||||

| 920-950 | 6 | 920-960 | 6 | 150-2000 | ||||

| 1020-1060 | 6 | 150-2000 | ||||||

| 1070-1110 | 6 | 150-2000 | ||||||

| 1120-1160 | 6 | 150-2000 | ||||||

| 1220-1260 | 6 | 150-2000 |

|

|

|

|

|