Stainless Steel Compensator is used in the input and output of central air conditioning pump, fire pump, water supply pump, effectively reduce the host vibration, absorb pipeline noise, protect equipment, extend the service life of equipment with durable, high temperature resistance, high pressure resistance, anti-corrosion, environmental protection and other advantages.

Special design is allowable, welcome to contact us.

Stainless Steel Compensator is used in the input and output of central air conditioning pump, fire pump, water supply pump, effectively reduce the host vibration, absorb pipeline noise, protect equipment, extend the service life of equipment with durable, high temperature resistance, high pressure resistance, anti-corrosion, environmental protection and other advantages.

Special design is allowable, welcome to contact us.

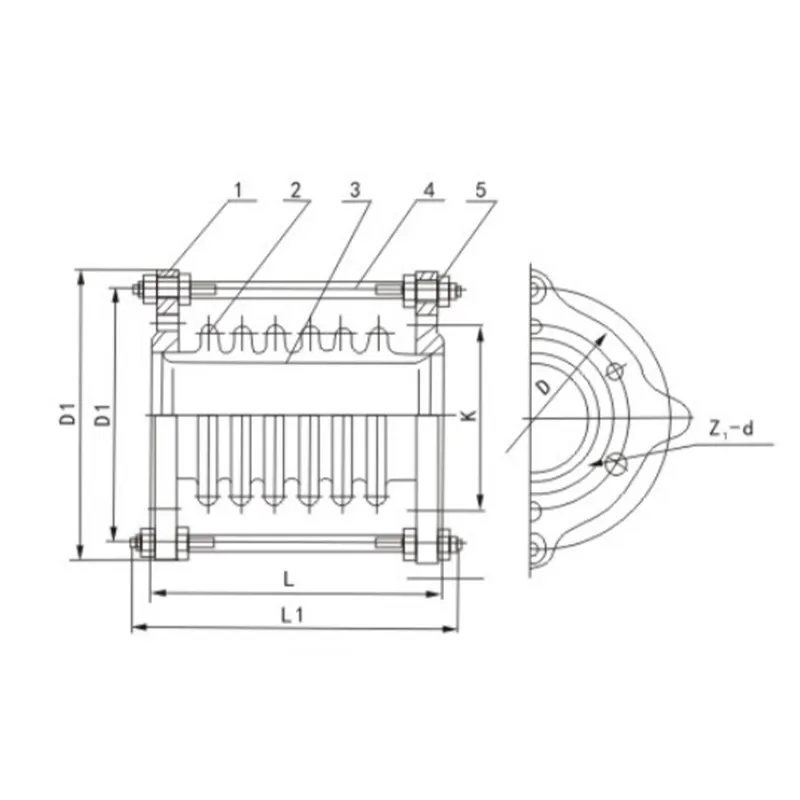

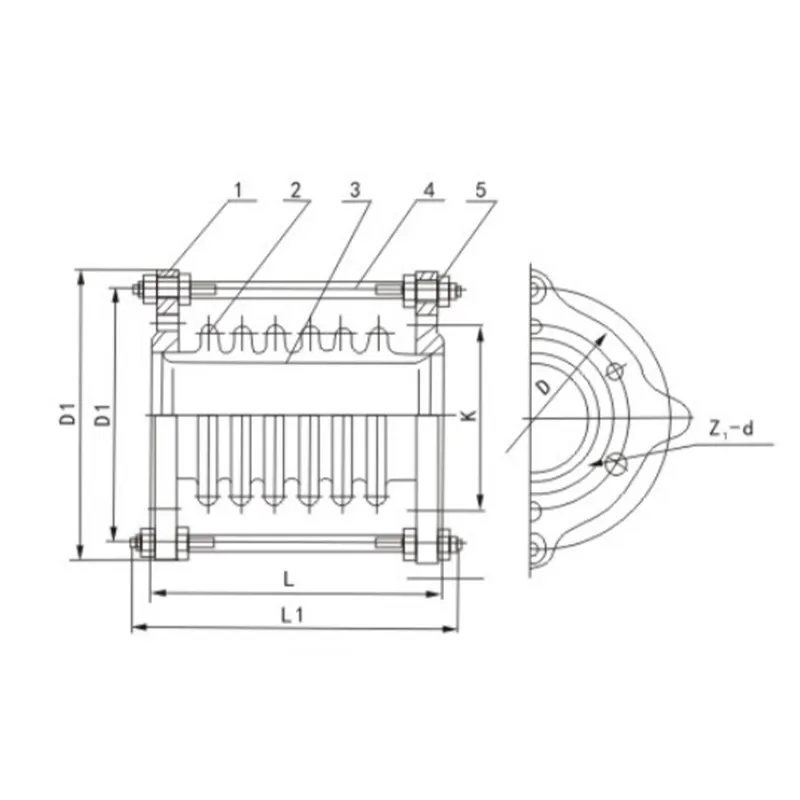

| Part No. | Part Name | Material | Standard |

| 1 | Lugs | Stainless Steel | EN 10088-1 |

| Flange | Stainless Steel | EN 1092 | |

| 2 | Bellow | Stainless Steel | EN 10088-3 |

| 3 | Draft Tube | Stainless Steel | EN 10088-3 |

| 4 | Pull Rod | Carbon Steel / Stainless Steel | EN 10084/EN 10088-3 |

| 5 | Nuts | Carbon Steel 6.8,8.8/Stainless Steel | EN 10084/EN 10088-3 |

| Briefs & Features | |

| 1 | Suitable for all kinds of water piping, fire piping, air conditioning piping, steam piping, etc. |

| 2 | Working pressure PN10/PN16/PN25. |

| 3 | Maximum temperature -196°C~450°C. |

| 4 | Total angle deviation is 5-30 degree. |

| Complying Standard | |

| Flange drilling | EN1092-2, EN1092-1, ANSI |

| Body | EN10088-1 |

| Test | EN12266-1 |

| DN | Overall Length (L) | Maximum Size of Bellows | Maximum Radial Dimensions | Direction | Compensation Level | |||||

| Compensator X0(mm) | Rigidity Kx0(N/mm) | |||||||||

| Design Pressure Pd MPa | ||||||||||

| 0.6 | 1.0 | 1.6 | 0.6 | 1.0 | 1.6 | |||||

| 50 | 96 | 48 | 200 | 115 | 12 | 10 | 219 | 467 | 859 | a |

| 156 | 31 | 24 | 20 | 109 | 233 | 429 | b | |||

| 65 | 100 | 70 | 230 | 16 | 12 | 9 | 261 | 568 | 1100 | a |

| 160 | 32 | 24 | 19 | 131 | 284 | 550 | b | |||

| 80 | 100 | 95 | 250 | 16 | 12 | 9 | 304 | 676 | 1287 | a |

| 160 | 32 | 24 | 18 | 152 | 338 | 644 | b | |||

| 100 | 124 | 153 | 290 | 19 | 15 | 12 | 466 | 831 | 1396 | a |

| 204 | 38 | 31 | 25 | 233 | 415 | 696 | b | |||

| 125 | 128 | 200 | 330 | 19 | 15 | 12 | 533 | 996 | 1682 | a |

| 208 | 38 | 30 | 24 | 267 | 1498 | 841 | b | |||

| 150 | 128 | 297 | 360 | 18 | 15 | 12 | 637 | 1170 | 1980 | a |

| 208 | 37 | 29 | 23 | 318 | 585 | 990 | b | |||

| 200 | 168 | 527 | 420 | 36 | 29 | 24 | 427 | 702 | 1345 | a |

| 288 | 72 | 58 | 47 | 214 | 351 | 973 | b | |||

| 250 | 172 | 769 | 485 | 36 | 28 | 23 | 510 | 851 | 1649 | a |

| 292 | 72 | 57 | 46 | 255 | 426 | 825 | b | |||

| 300 | 200 | 1064 | 545 | 45 | 36 | 30 | 442 | 724 | 1384 | a |

| 344 | 90 | 73 | 59 | 221 | 662 | 692 | b | |||

| 350 | 200 | 1257 | 610 | 45 | 66 | 29 | 475 | 784 | 1508 | a |

| 344 | 90 | 72 | 58 | 237 | 392 | 754 | b | |||

| 400 | 204 | 1605 | 670 | 44 | 35 | 28 | 530 | 882 | 1708 | a |

| 348 | 89 | 70 | 57 | 265 | 441 | 854 | b | |||

| 450 | 204 | 1987 | 720 | 45 | 34 | 28 | 582 | 980 | 1902 | a |

| 348 | 89 | 69 | 56 | 291 | 490 | 951 | b | |||

| 500 | 208 | 2411 | 790 | 43 | 34 | 28 | 640 | 1079 | 2102 | a |

| 280 | 64 | 50 | 42 | 427 | 719 | 1401 | b | |||

| 600 | 312 | 3452 | 900 | 73 | 50 | 38 | 540 | 1463 | 3202 | a |

| 432 | 110 | 75 | 57 | 360 | 975 | 2135 | b | |||