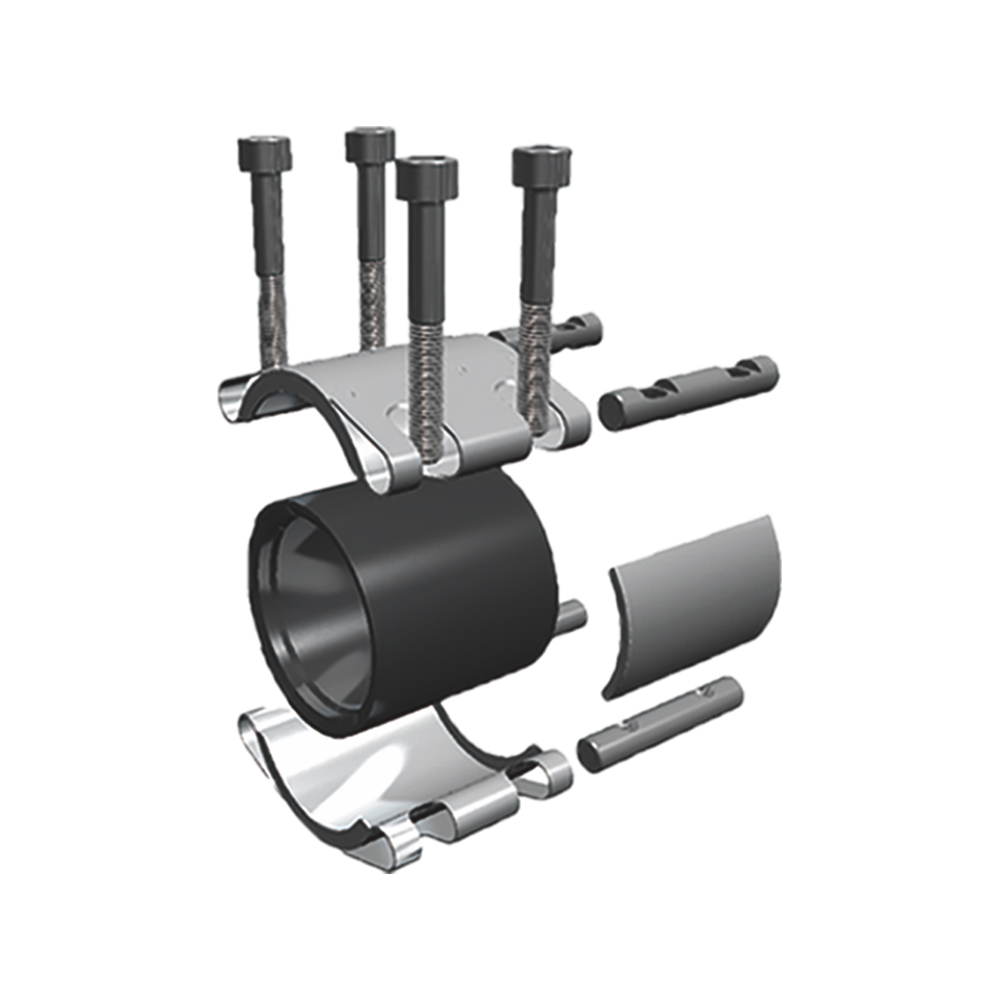

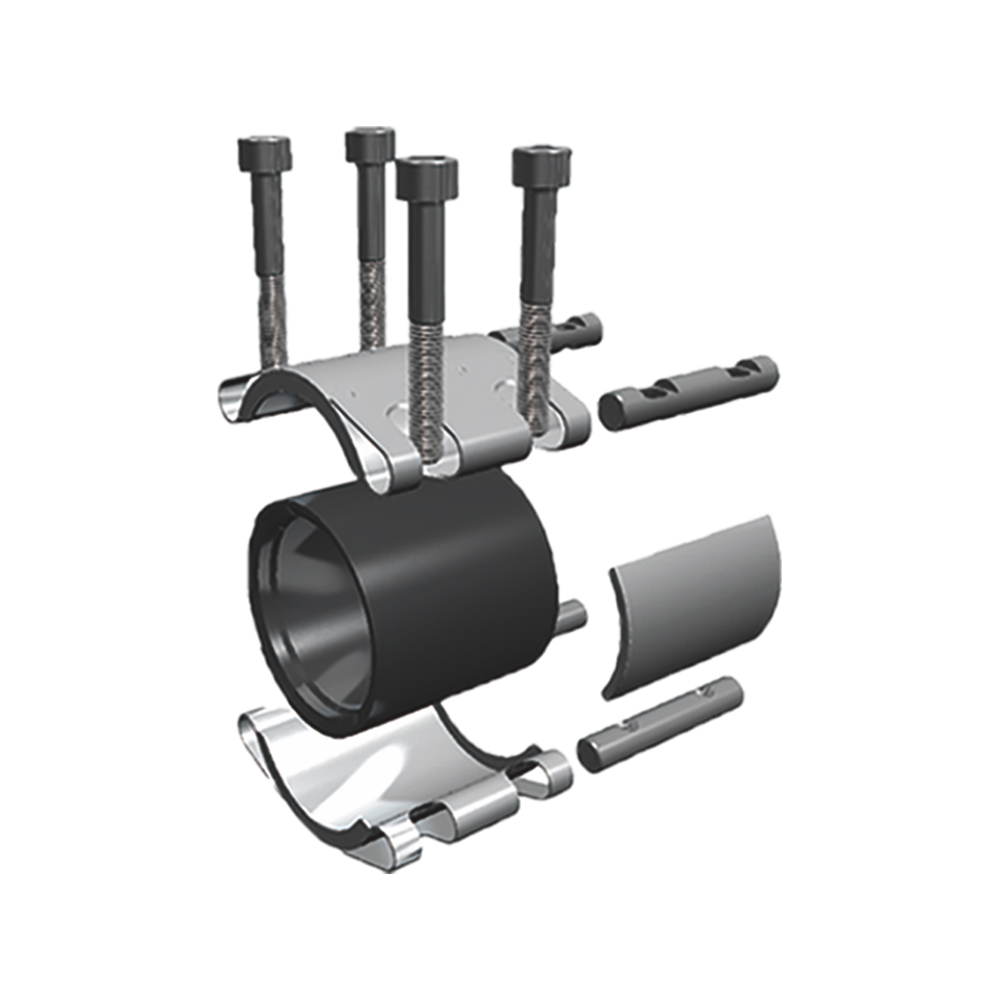

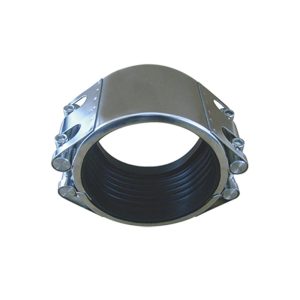

Stainless Steel Repair Clamp is mainly used for the rapid repair of pipeline leakage. It can repair the sand holes and breaks caused by aging and rust without changing the pipeline. It is easy to install and have highconstruction efficiency. It can be operated without special tools.

Special design is allowable, welcome to contact us.

Stainless Steel Repair Clamp is mainly used for the rapid repair of pipeline leakage. It can repair the sand holes and breaks caused by aging and rust without changing the pipeline. It is easy to install and have highconstruction efficiency. It can be operated without special tools.

Special design is allowable, welcome to contact us.

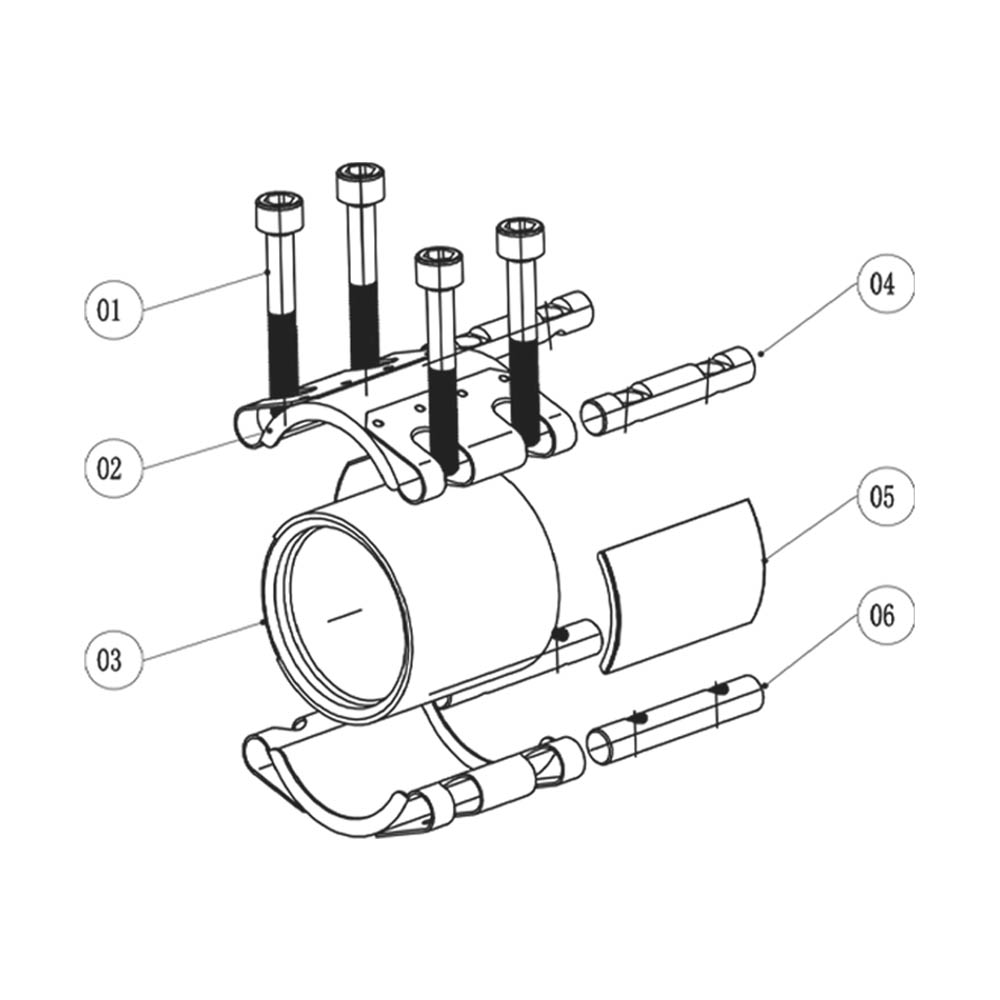

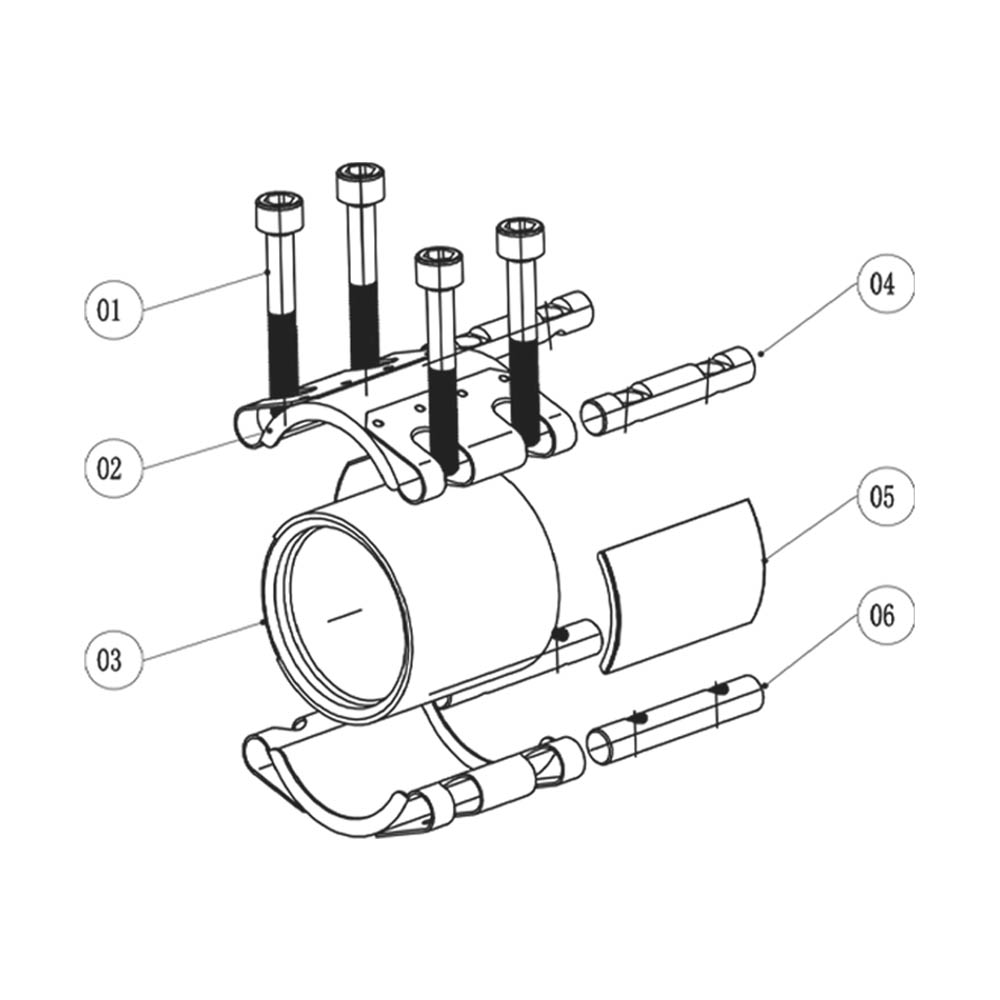

| Part No. | Part Name | Material | Standard |

| 1 | Backplate | SS304 | AS4181-2013 |

| 2、3 | Bolts&Nuts | SS304 | AS4181-2013 |

| 4 | Rubber Sleeve | EPDM | ISO4633 |

| 5 | Shell Steel Plate | SS304 | AS4181-2013 |

| 6 | Bolts | SS304 | AS4181-2013 |

| Briefs & Features | |

| 1 | Suitable for steel, iron, plastic pipes, wide range of pipe diameters. |

| 2 | Working pressure PN10/PN16. |

| 3 | Maximum temperature -10°C to+70°C. |

| 4 | Suitable for potable water (WRAS approved), recycled water and sewage. Corrosion resistant structure. |

|

|

|

|

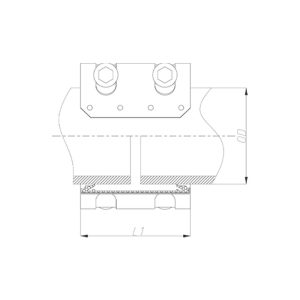

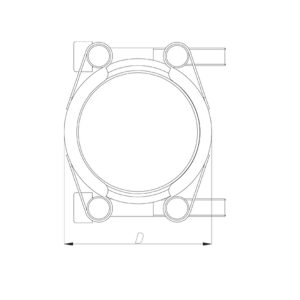

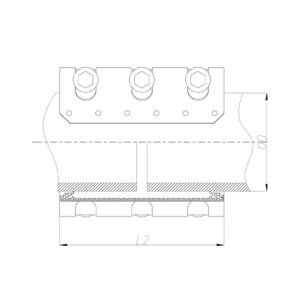

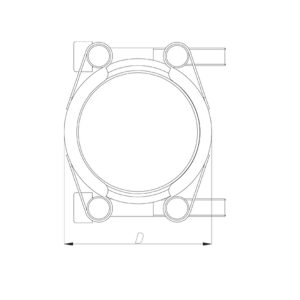

| (mm) | ODmin-ODmax(mm) | WP(bar) | L1(mm) | L2(mm) | D (mm) | Bolts(M) | Nm |

| 18 | 17-19 | 32 | 57 | 35 | 6 | 10 | |

| 21.7 | 21-23 | 32 | 57 | 45 | 6 | 10 | |

| 25 | 24.5-25.5 | 32 | 57 | 50 | 6 | 10 | |

| 27.2 | 26-28 | 32 | 57 | 50 | 6 | 10 | |

| 32 | 31.5-32.5 | 32 | 57 | 55 | 6 | 10 | |

| 34 | 33-35 | 32 | 57 | 55 | 6 | 10 | |

| 40 | 39.5-41.5 | 32 | 57 | 55 | 6 | 10 | |

| 42 | 42-44 | 32 | 57 | 139 | 65 | 6 | 15 |

| 44.5 | 44-45.1 | 32 | 57 | 139 | 65 | 6 | 15 |

| 48.6 | 47-49 | 32 | 57 | 203 | 70 | 6 | 15 |

| 54 | 53.6-54.6 | 32 | 57 | 203 | 70 | 8 | 30 |

| 57 | 56.3-577 | 32 | 57 | 203 | 80 | 8 | 30 |

| 60.3 | 59-62 | 32 | 80 | 203 | 85 | 8 | 30 |

| 63 | 62.2-63.9 | 32 | 80 | 203 | 85 | 8 | 30 |

| 76.1 | 75-78 | 28 | 80 | 203 | 100 | 8 | 30 |

| 79.9 | 78.8-80.8 | 28 | 80 | 203 | 100 | 8 | 30 |

| 88.9 | 88-92 | 28 | 107 | 203 | 110 | 10 | 50 |

| 108 | 106-110 | 28 | 107 | 203 | 130 | 10 | 50 |

| 110 | 108.9-111.2 | 28 | 107 | 203 | 130 | 10 | 50 |

| 114.3 | 112-116 | 28 | 107 | 203 | 135 | 10 | 50 |

| 118 | 116.6-119.2 | 28 | 107 | 203 | 140 | 10 | 50 |

| 125 | 123.6-126.5 | 28 | 107 | 255 | 150 | 10 | 50 |

| 133 | 131.5-134.4 | 28 | 107 | 255 | 160 | 10 | 50 |

| 140 | 137-143 | 28 | 116 | 255 | 165 | 12 | 80 |

| 159 | 157-161 | 24 | 116 | 255 | 185 | 12 | 80 |

| 165.2 | 163.3-166.7 | 24 | 116 | 255 | 190 | 12 | 80 |

| 168 | 166-170 | 24 | 116 | 255 | 195 | 12 | 80 |

| 170 | 168.2-171.9 | 24 | 116 | 255 | 195 | 12 | 80 |

| 200 | 198.2-201.5 | 16 | 155 | 255 | 240 | 14 | 100 |

| 219 | 217-221 | 16 | 155 | 255 | 250 | 14 | 100 |

| 250 | 250-254 | 16 | 155 | 255 | 285 | 14 | 100 |

| 273 | 271-275 | 16 | 155 | 255 | 305 | 14 | 100 |

| 315 | 313-317 | 14 | 155 | 255 | 340 | 14 | 100 |

| 325 | 323-327 | 14 | 155 | 255 | 355 | 14 | 100 |

| 355.6 | 354-358 | 14 | 155 | 255 | 385 | 14 | 100 |

| 377 | 375-379 | 14 | 155 | 255 | 410 | 14 | 100 |

|

|