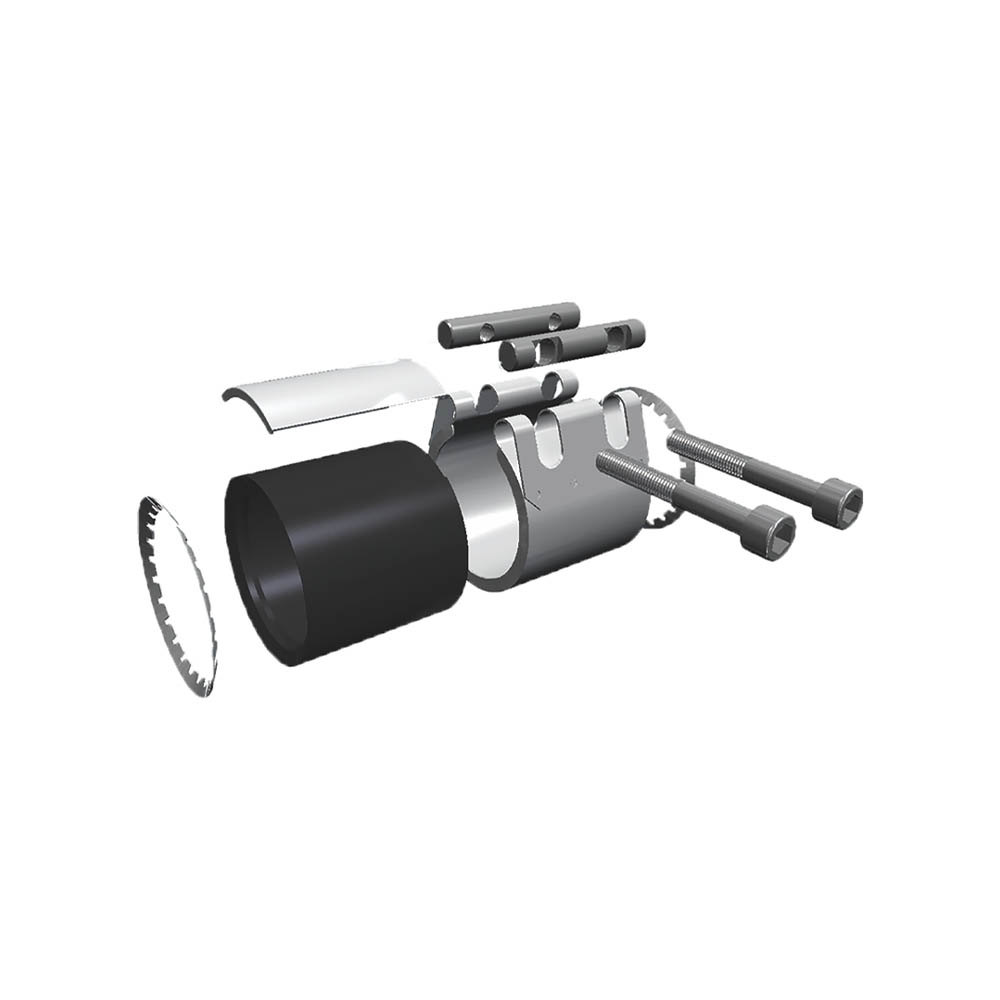

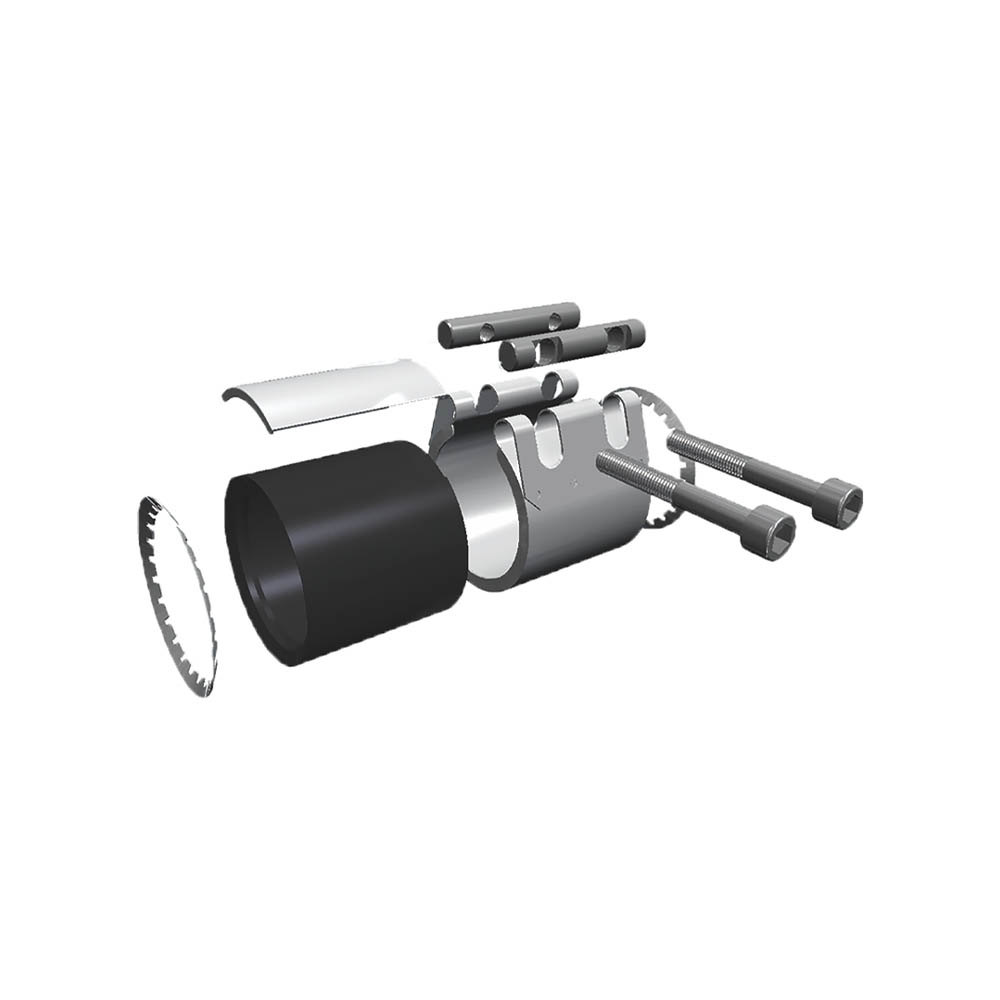

FCTR Stainless Steel Repair Clamps is ring gear type pipe connector, which has strong sealing performance and tensile strength. It is used to connect PE and other non-metallic pipes. Its ring gear design can play a good role in anti-seismic, anti impact and noise reduction in pipe connection.

Special design is allowable, welcome to contact us.

FCTR Stainless Steel Repair Clamps is ring gear type pipe connector, which has strong sealing performance and tensile strength. It is used to connect PE and other non-metallic pipes. Its ring gear design can play a good role in anti-seismic, anti impact and noise reduction in pipe connection.

Special design is allowable, welcome to contact us.

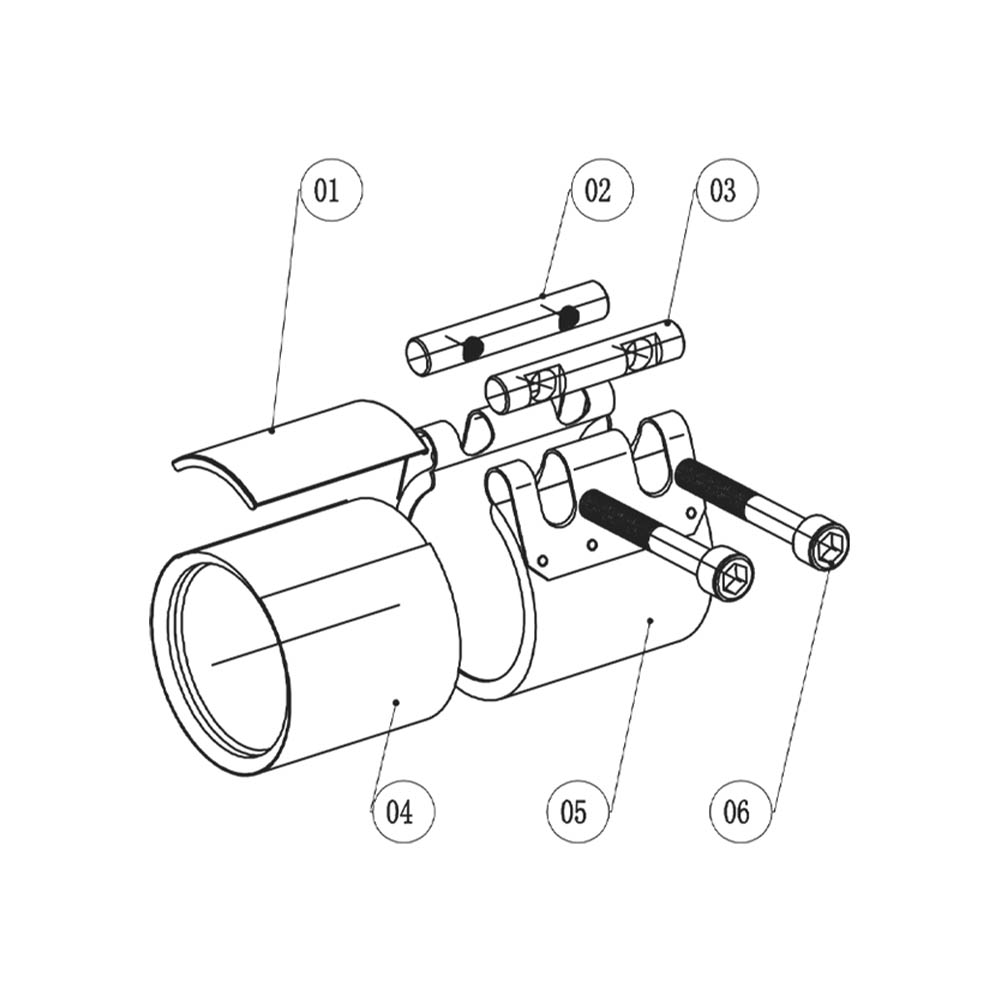

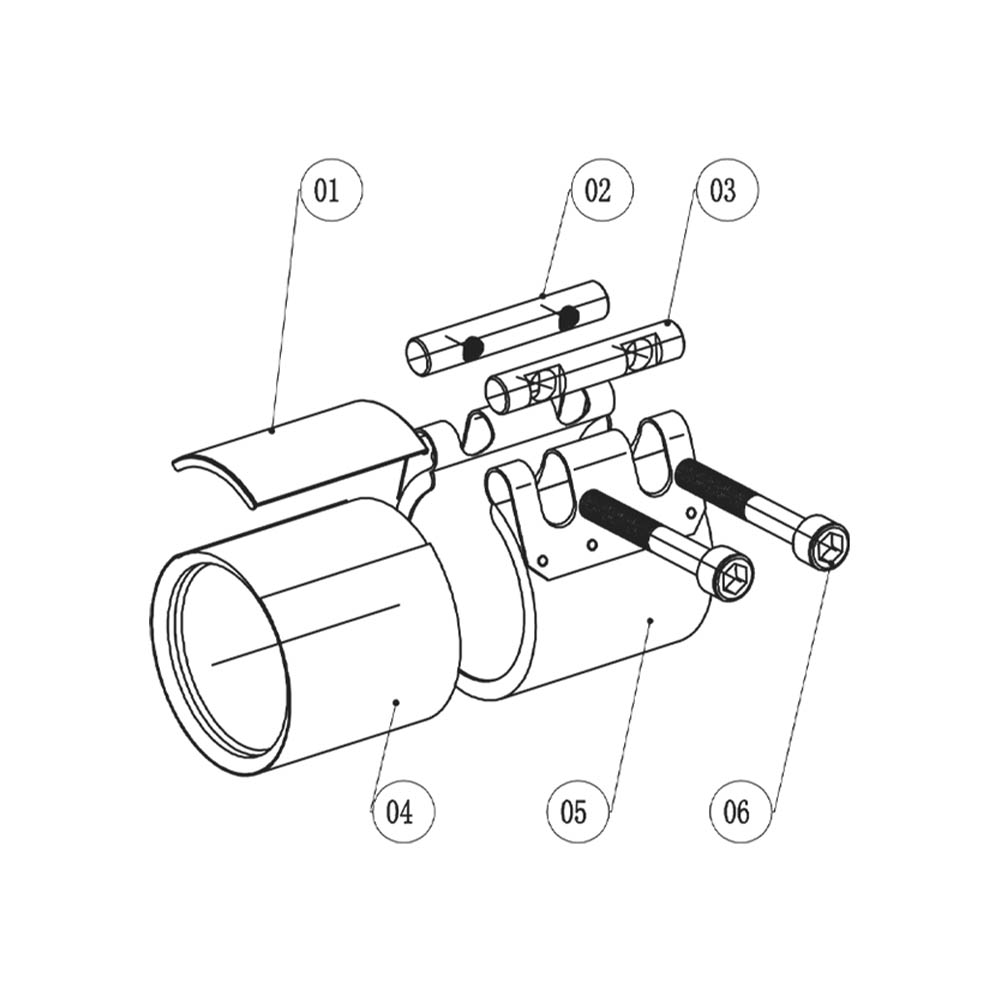

| Part No. | Part Name | Material | Standard |

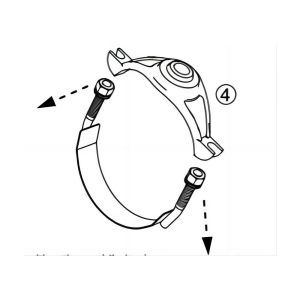

| 1 | Backplate | SS304 | AS4181-2013 |

| 2、3 | Bolts&Nuts | SS304 | AS4181-2013 |

| 4 | Rubber Sleeve | EPDM | ISO4633 |

| 5 | Shell Steel Plate | SS304 | AS4181-2013 |

| 6 | Bolts | SS304 | AS4181-2013 |

| Briefs & Features | |

| 1 | Suitable for PE and other non-metallic pipes(FCTR), metal, cement, asbestos and other materials.(FCD), wide range of pipe diameters. |

| 2 | Working pressure PN10/PN16. |

| 3 | Maximum temperature -10°C to+70°C. |

| 4 | Suitable for potable water (WRAS approved), recycled water and sewage. Corrosion resistant structure. |

|

|

|

|

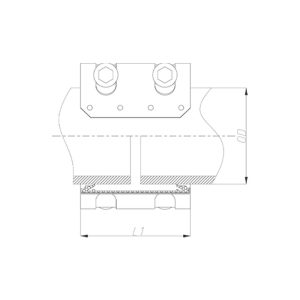

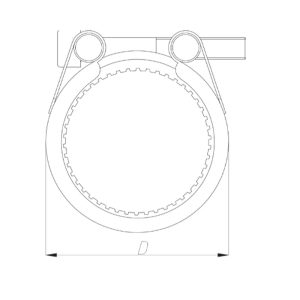

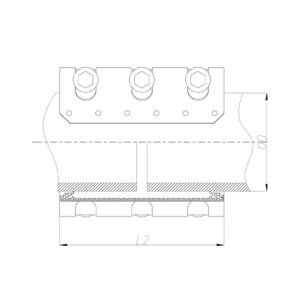

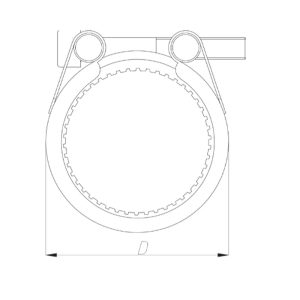

| OD | ODmin-ODmax | PN | WP | L1 | L2 | D |

| (mm) | (mm) | (bar) | (bar) | (mm) | (mm) | (mm) |

| 25 | 31-35 | 16 | 16 | 150 | 200 | 300 |

| 32 | 39-43 | 16 | 16 | 150 | 200 | 300 |

| 40 | 48-52 | 16 | 16 | 150 | 200 | 300 |

| 50 | 59-63 | 16 | 16 | 150 | 200 | 300 |

| 65 | 72-77 | 16 | 16 | 150 | 200 | 300 |

| 80 | 88-92 | 16 | 16 | 150 | 200 | 300 |

| 100 | 108-114 | 16 | 16 | 150 | 200 | 300 |

| 125 | 138-144 | 16 | 16 | 150 | 200 | 300 |

| 150 | 165-171 | 16 | 16 | 150 | 200 | 300 |

| 200 | 216-222 | 16 | 16 | 150 | 200 | 300 |

| 250 | 270-276 | 16 | 16 | 150 | 200 | 300 |

| 300 | 318-326 | 16 | 16 | 150 | 200 | 300 |

|

|

|

|

|

|