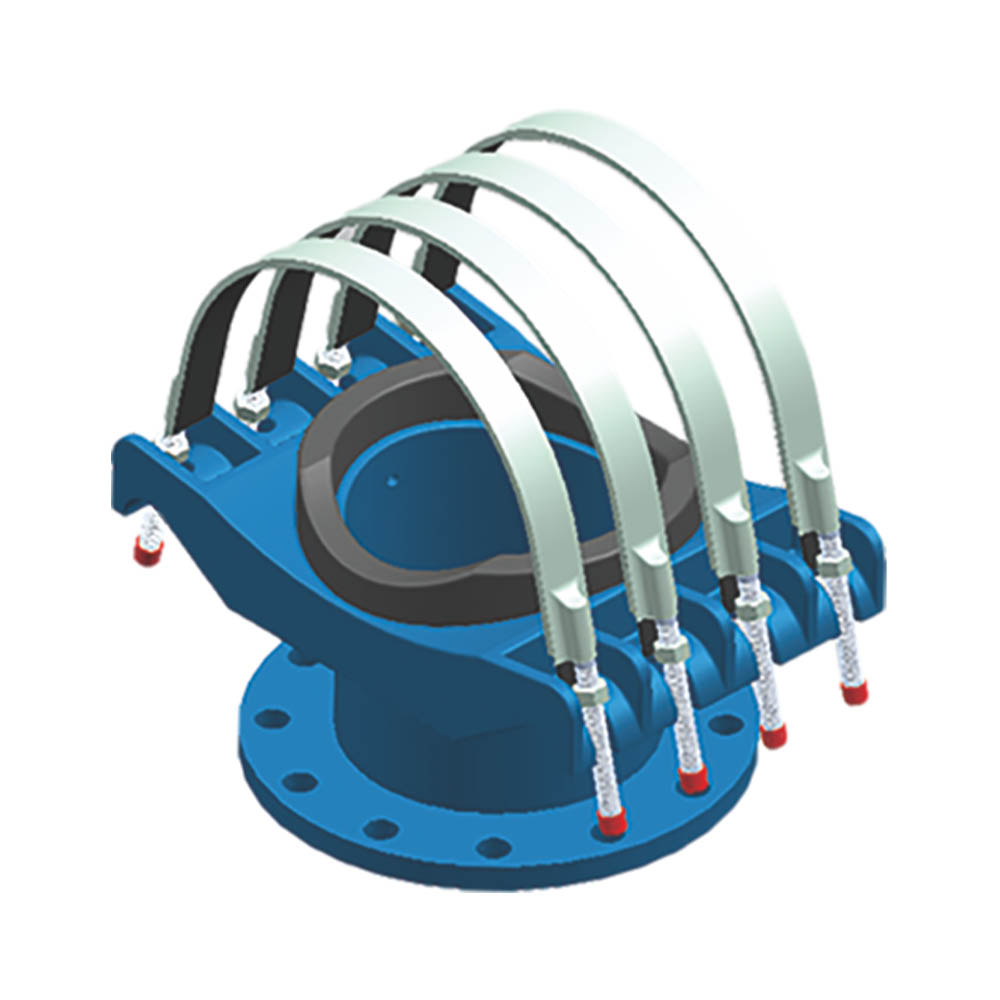

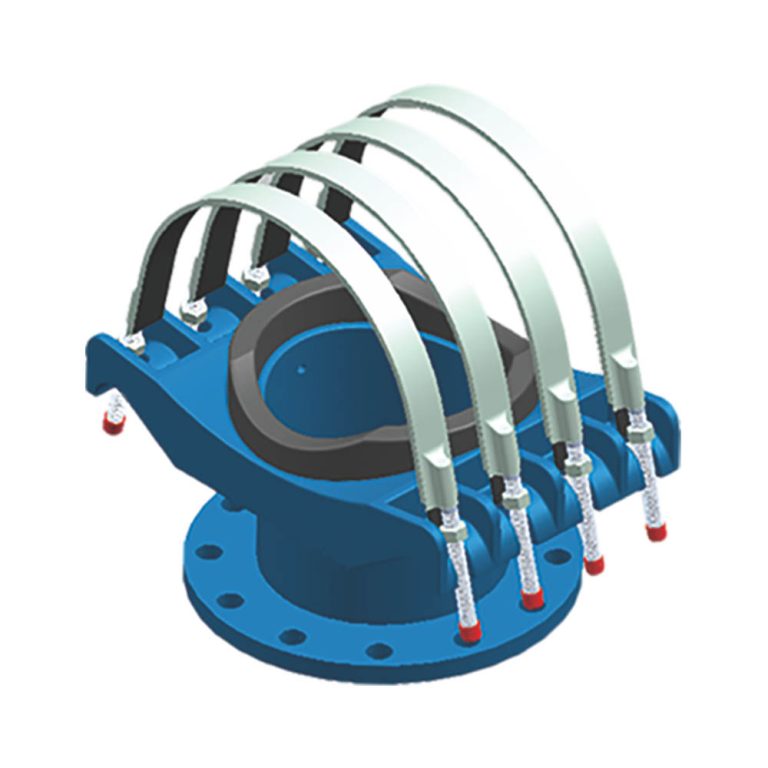

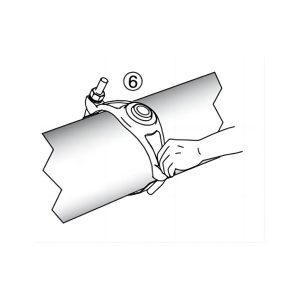

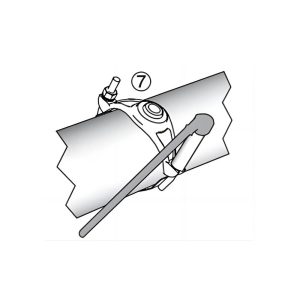

Universal Saddle Clamp is used for DI/PE/PVC and Steel pipes during opening branch, or installation of faucets, water meters etc. It can be compatible with all kinds of pipes under the same nominal diameter, greatly reducing the inventory of the pipe installation company. High-strength bolts can be supplied. Install easily and remove conveniently. It can be non-stop to install the product.

Special design is allowable, welcome to contact us.

Universal Saddle Clamp is used for DI/PE/PVC and Steel pipes during opening branch, or installation of faucets, water meters etc. It can be compatible with all kinds of pipes under the same nominal diameter, greatly reducing the inventory of the pipe installation company. High-strength bolts can be supplied. Install easily and remove conveniently. It can be non-stop to install the product.

Special design is allowable, welcome to contact us.

| Part No. | Part Name | Material | Standard |

| 1 | Body | GGG50 | EN1563 |

| 2 | Gasket | EPDM/SBR/NBR | ISO4633 |

| 3 | Bolts&Nuts | SS304 | AS4181-2013 |

| 4 | Finish Layer | Fusion Bond Epoxy etc. | EN14901 |

| Briefs & Features | |

| 1 | Suitable for steel, iron, plastic pipes, wide range of pipe diameters. |

| 2 | Working pressure PN10/PN16. |

| 3 | Maximum temperature -10°C to+70°C. |

| 4 | Suitable for potable water (WRAS approved), recycled water and sewage. Corrosion resistant structure. |

| Complying Standard | |

| Flange drilling | EN1092-2, EN1092-1, ANSI |

| Coating | EN30677 |

| Test | EN12266-1 |

|

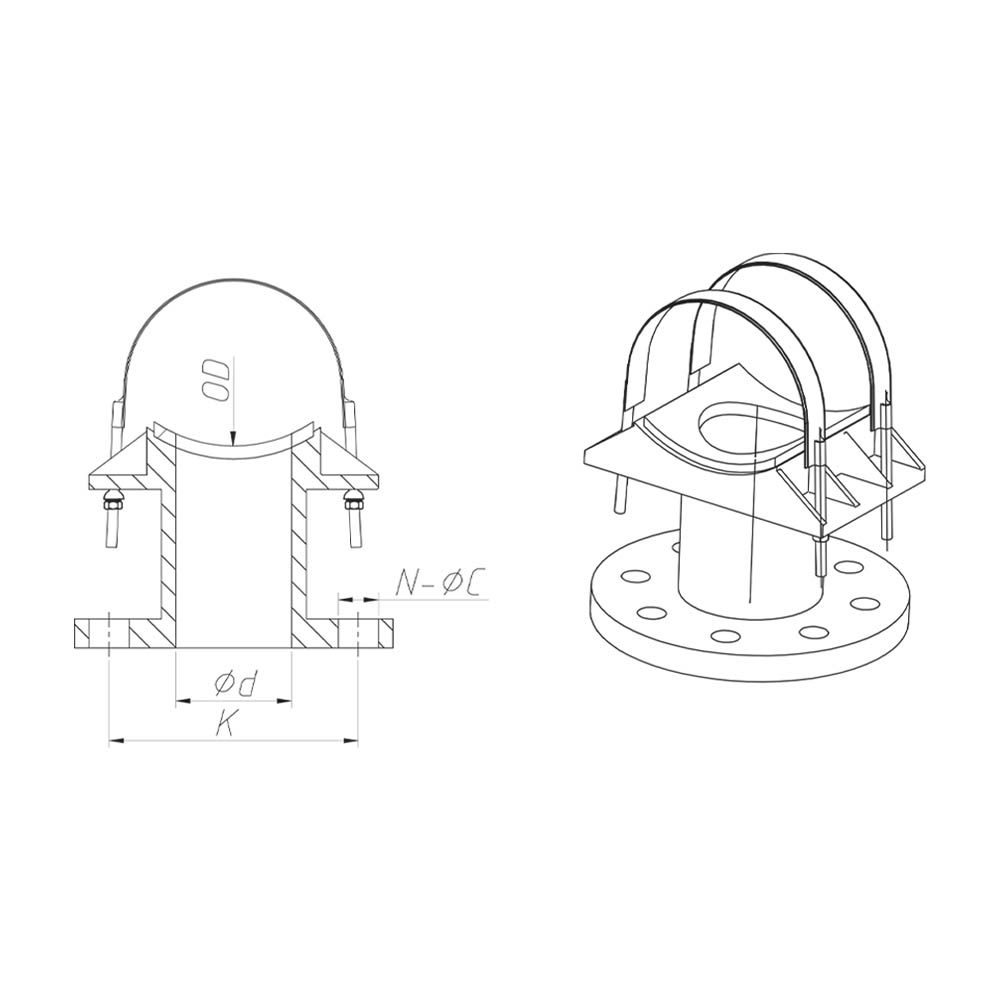

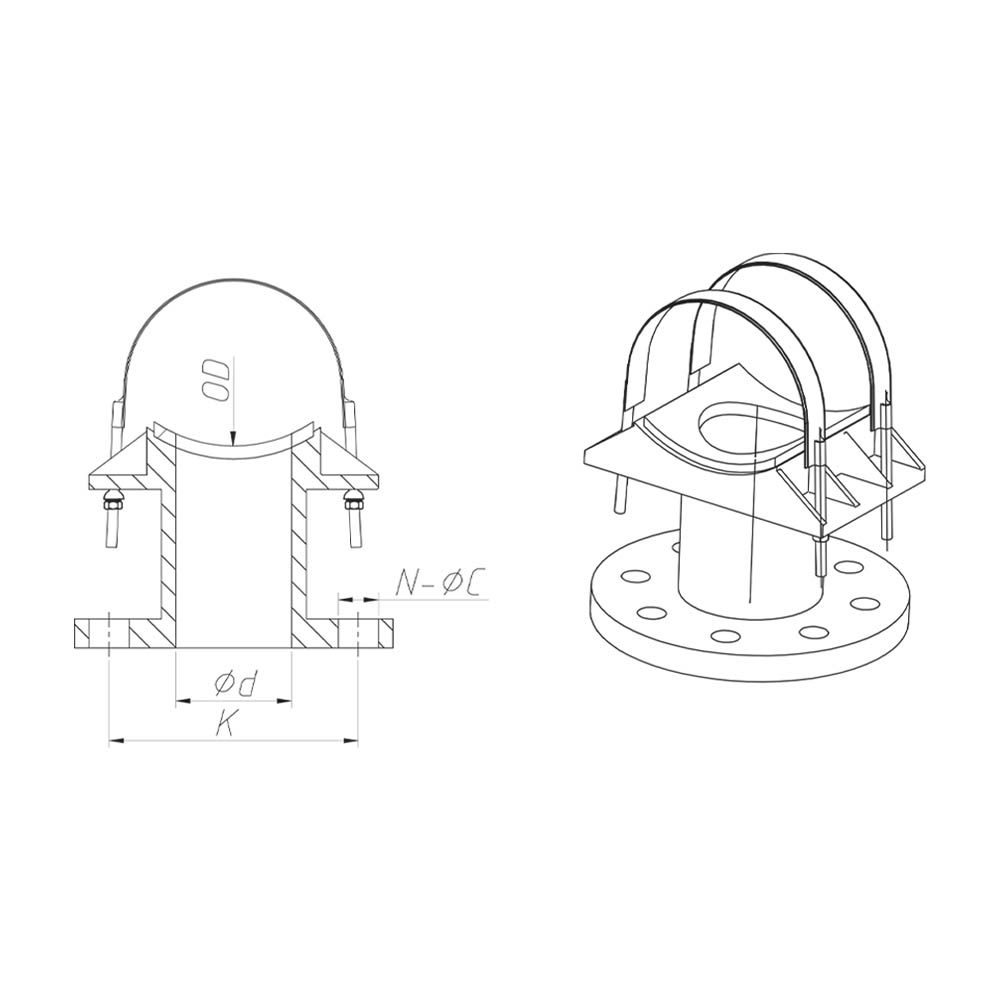

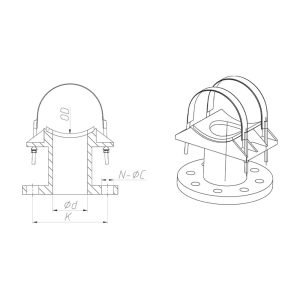

| OD | Specification | ∅d | K | N | C |

| 75-98 | DN80*50 | 50 | 125 | 4 | 19 |

| 97-118 | DN100*50 | 50 | 125 | 4 | 19 |

| DN100*65 | 65 | 145 | 4 | 19 | |

| DN100*80 | 80 | 160 | 8 | 19 | |

| 126-148 | DN125*50 | 50 | 125 | 4 | 19 |

| DN125*65 | 65 | 145 | 4 | 19 | |

| DN125*80 | 80 | 160 | 8 | 19 | |

| DN125*100 | 100 | 180 | 8 | 19 | |

| 158-177 | DN150*50 | 50 | 125 | 4 | 19 |

| DN150*65 | 65 | 145 | 4 | 19 | |

| DN150*80 | 80 | 160 | 8 | 19 | |

| DN150*100 | 100 | 180 | 8 | 19 | |

| 206-233 | DN200*50 | 50 | 125 | 4 | 19 |

| DN200*65 | 65 | 145 | 4 | 19 | |

| DN200*80 | 80 | 160 | 8 | 19 | |

| DN200*100 | 100 | 180 | 8 | 19 | |

| DN200*125 | 125 | 210 | 8 | 19 | |

| DN200*150 | 150 | 240 | 8 | 23 | |

| 260-286 | DN250*50 | 50 | 125 | 4 | 19 |

| DN250*65 | 65 | 145 | 4 | 19 | |

| DN250*80 | 80 | 160 | 8 | 19 | |

| DN250*100 | 100 | 180 | 8 | 19 | |

| DN250*125 | 125 | 210 | 8 | 19 | |

| DN250*150 | 150 | 240 | 8 | 23 | |

| DN250*200 | 200 | 295 | 12 | 23 | |

| 313-338 | DN300*50 | 50 | 125 | 4 | 19 |

| DN300*65 | 65 | 145 | 4 | 19 | |

| DN300*80 | 80 | 160 | 8 | 19 | |

| DN300*100 | 100 | 180 | 8 | 19 | |

| DN300*125 | 125 | 210 | 8 | 19 | |

| DN300*150 | 150 | 240 | 8 | 23 | |

| DN300*200 | 200 | 295 | 12 | 23 | |

| 344-372 | DN350*50 | 50 | 125 | 4 | 19 |

| DN350*65 | 65 | 145 | 4 | 19 | |

| DN350*80 | 80 | 160 | 8 | 19 | |

| DN350*100 | 100 | 180 | 8 | 19 | |

| DN350*125 | 125 | 210 | 8 | 19 | |

| DN350*150 | 150 | 240 | 8 | 23 | |

| DN350*200 | 200 | 295 | 12 | 23 | |

| DN350*250 | 250 | 355 | 12 | 28 | |

| 418-443 | DN400*50 | 50 | 125 | 4 | 19 |

| DN400*65 | 65 | 145 | 4 | 9 | |

| DN400*80 | 80 | 160 | 8 | 19 | |

| DN400*100 | 100 | 180 | 8 | 19 | |

| DN400*125 | 125 | 210 | 8 | 19 | |

| DN400*150 | 150 | 240 | 8 | 23 | |

| DN400*200 | 200 | 295 | 12 | 23 | |

| DN400*250 | 250 | 355 | 12 | 28 | |

| DN400*300 | 300 | 410 | 12 | 28 | |

| 510-544 | DN500*50 | 50 | 125 | 4 | 19 |

| DN500*65 | 65 | 145 | 4 | 19 | |

| DN500*80 | 80 | 160 | 8 | 19 | |

| DN500*100 | 100 | 180 | 8 | 19 | |

| DN500*125 | 125 | 210 | 8 | 19 | |

| DN500*150 | 150 | 240 | 8 | 23 | |

| DN500*200 | 200 | 295 | 12 | 23 | |

| DN500*250 | 250 | 355 | 12 | 28 | |

| DN500*300 | 300 | 410 | 12 | 28 | |

| DN500*350 | 350 | 470 | 16 | 28 | |

| DN500*400 | 400 | 525 | 16 | 31 | |

| 610-647 | DN600*50 | 50 | 125 | 4 | 19 |

| DN600*65 | 65 | 145 | 4 | 19 | |

| DN600*80 | 80 | 160 | 8 | 19 | |

| DN600*100 | 100 | 180 | 8 | 19 | |

| DN600*125 | 125 | 210 | 8 | 19 | |

| DN600*150 | 150 | 240 | 8 | 23 | |

| DN600*200 | 200 | 295 | 12 | 23 | |

| DN600*250 | 250 | 355 | 12 | 28 | |

| DN600*300 | 300 | 410 | 12 | 28 | |

| DN600*350 | 350 | 470 | 16 | 28 | |

| DN600*400 | 400 | 525 | 16 | 31 | |

| DN600*450 | 450 | 585 | 20 | 31 | |

| DN600*500 | 500 | 650 | 20 | 34 | |

| 710-744 | DN700*50 | 50 | 125 | 4 | 19 |

| DN700*65 | 65 | 145 | 4 | 19 | |

| DN700*80 | 80 | 160 | 8 | 19 | |

| DN700*100 | 100 | 180 | 8 | 19 | |

| DN700*125 | 125 | 210 | 8 | 19 | |

| DN700*150 | 150 | 240 | 8 | 23 | |

| DN700*200 | 200 | 295 | 12 | 23 | |

| DN700*250 | 250 | 355 | 12 | 28 | |

| DN700*300 | 300 | 410 | 12 | 28 | |

| DN700*350 | 350 | 470 | 16 | 28 | |

| DN700*400 | 400 | 525 | 16 | 31 | |

| DN700*450 | 450 | 585 | 20 | 31 | |

| DN700*500 | 500 | 650 | 20 | 34 | |

| DN700*600 | 600 | 770 | 20 | 37 | |

| 820-855 | DN800*50 | 50 | 125 | 4 | 19 |

| DN800*65 | 65 | 145 | 4 | 19 | |

| DN800*80 | 80 | 160 | 8 | 19 | |

| DN800*100 | 100 | 180 | 8 | 19 | |

| DN800*125 | 125 | 210 | 8 | 19 | |

| DN800*150 | 150 | 240 | 8 | 23 | |

| DN800*200 | 200 | 295 | 12 | 23 | |

| DN800*250 | 250 | 355 | 12 | 28 | |

| DN800*300 | 300 | 410 | 12 | 28 | |

| DN800*350 | 350 | 470 | 16 | 28 | |

| DN800*400 | 400 | 525 | 16 | 31 | |

| DN800*450 | 450 | 585 | 20 | 31 | |

| DN800*500 | 500 | 650 | 20 | 34 | |

| DN800*600 | 600 | 770 | 20 | 37 | |

| DN800*700 | 700 | 840 | 24 | 37 | |

| 1025-1055 | DN1000*50 | 50 | 125 | 4 | 19 |

| DN1000*65 | 65 | 145 | 8 | 19 | |

| DN1000*80 | 80 | 160 | 8 | 19 | |

| DN1000*100 | 100 | 180 | 8 | 19 | |

| DN1000*125 | 125 | 210 | 8 | 19 | |

| DN1000*150 | 150 | 240 | 8 | 23 | |

| DN1000*200 | 200 | 295 | 12 | 23 | |

| DN1000*250 | 250 | 355 | 12 | 28 | |

| DN1000*300 | 300 | 410 | 12 | 28 | |

| DN1000*350 | 350 | 470 | 16 | 28 | |

| DN1000*400 | 400 | 525 | 16 | 31 | |

| DN1000*450 | 450 | 585 | 20 | 31 | |

| DN1000*500 | 500 | 650 | 20 | 34 | |

| DN1000*600 | 600 | 770 | 20 | 37 | |

| DN1000*700 | 700 | 840 | 24 | 37 | |

| DN1000*800 | 800 | 950 | 24 | 41 |

|

|

|

|

|