Understanding Pipe Repair Clamps

What Are Pipe Repair Clamps?

Ремонтные зажимы are vital tools crafted to fix leaks or damage in pipelines swiftly. They surround the harmed section of a pipe. This seals it tightly to stop further leaks. These devices offer a fast alternative to replacing whole pipe segments. They save both time and resources. A repair clamp pipe works on various pipe types. These include metal, plastic, or composite materials. Its versatility makes it a go-to solution for many repair needs.

The design ensures a secure fit. It prevents fluid or gas escape. Pipe repair clamps are simple yet effective. They reduce downtime in critical systems. Whether for home or industrial use, they provide reliable fixes. Their ease of use makes them popular across sectors.

Common Materials Used in Pipe Repair Clamps

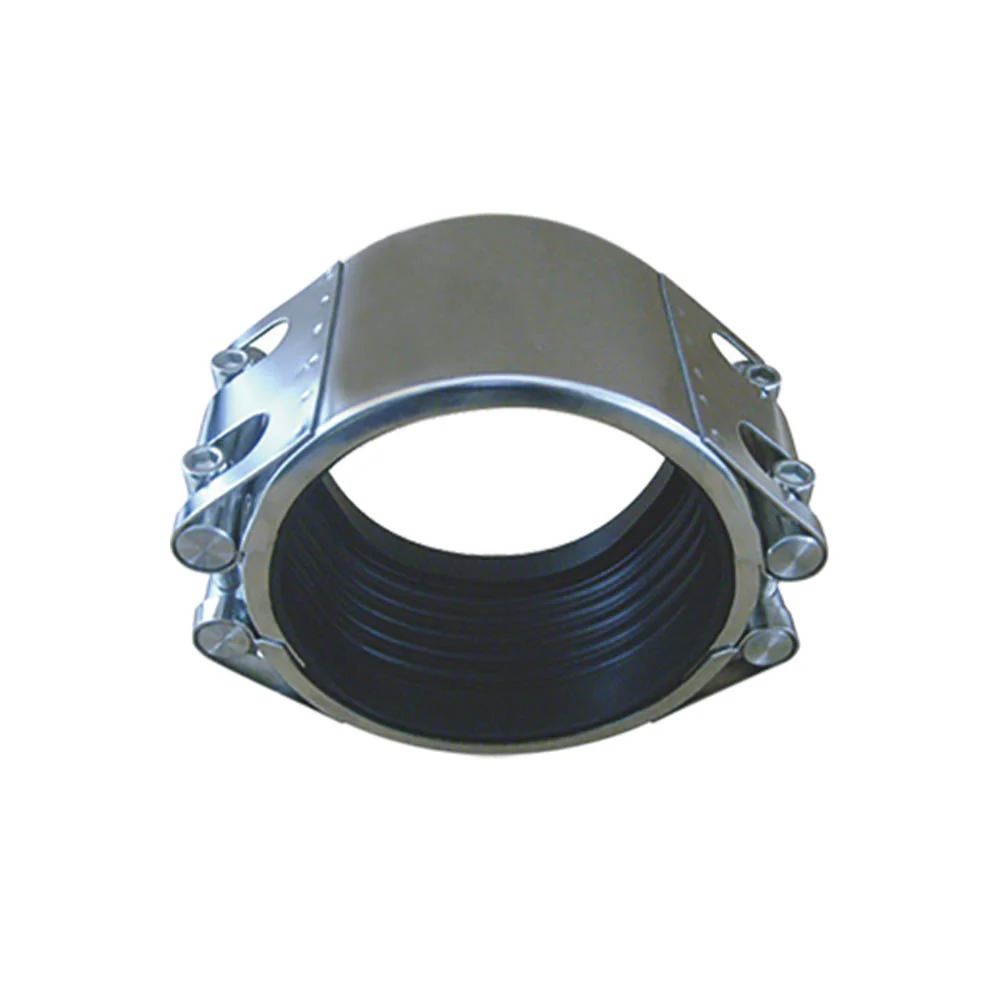

Pipe repair clamps are made from sturdy materials. These ensure strength and dependability. Stainless steel is a top choice. It resists rust and lasts long. This suits both indoor and outdoor settings. Ductile iron and aluminum are also used. The choice depends on the pipeline’s needs. Rubber gaskets are included in the design. They create a tight seal around the damaged spot.

Each material serves a purpose. Stainless steel handles tough conditions. Aluminum is lighter but still strong. Rubber gaskets adapt to pipe surfaces. They ensure no leaks persist. These materials combine to make pipe repair clamps durable. They withstand pressure and environmental stress.

Types of Pipe Repair Clamps Available

Many types of pipe repair clamps exist. Each meets specific repair needs. Single-band clamps are common for small fixes. They’re compact and easy to apply. Double-band or multi-band clamps handle bigger leaks. They suit high pressure pipe repair clamps for stronger sealing. Split sleeve clamps allow installation without cutting the pipeline. This saves effort and time.

Custom clamps can be made for unique cases. They fit odd pipe sizes or shapes. The variety ensures every issue has a solution. From minor drips to major breaks, pipe repair clamps adapt. Their range makes them essential in pipeline maintenance.

Applications of Pipe Repair Clamps

Situations Where Pipe Repair Clamps Are Useful

Pipe repair clamps shine when quick repairs are needed. They minimize downtime. They prevent further damage. These clamps fix sudden leaks in water lines, gas pipes, or industrial systems. They act as short-term solutions until full repairs are possible.

Their speed is a major advantage. A repair clamp pipe can stop leaks in minutes. This avoids costly delays. It also protects nearby equipment or areas. Whether in homes or factories, these clamps offer practical help. They’re a first line of defense against pipe failures.

Industries That Rely on Pipe Repair Clamps

Many sectors depend on pipe repair clamps. Water utilities use them to fix municipal networks. Leaks in water lines need fast solutions. These clamps deliver. Heating firms rely on them too. They repair heating pipes without halting service. Gas companies trust pipe repair clamps for safety. They seal gas leaks securely.

Oil and chemical plants also use them. These environments are harsh. Clamps must resist corrosion and chemicals. High pressure pipe repair clamps meet these demands. They keep systems running smoothly. Across industries, these tools ensure efficiency and safety.

Factors to Consider When Choosing a Pipe Repair Clamp

Compatibility with Different Pipe Materials

Choosing a pipe repair clamp requires checking pipe material. Each material has unique traits. These affect how clamps perform. Stainless steel clamps suit metal pipes well. They may not work for some plastics unless designed for them. Matching the clamp to the pipe is key. This ensures a strong, lasting seal.

Compatibility prevents issues like slipping or leaks. For composite pipes, special clamps may be needed. Always verify material match before buying. A wrong choice can weaken the repair. Proper selection makes the repair clamp pipe effective.

Size and Fit of the Clamp

Size and fit are critical for a pipe repair clamp. A well-fitted clamp seals tightly. It stops leaks completely. Measure the pipe’s diameter carefully. An oversized clamp may slip. An undersized one won’t close properly. Precision here is vital.

Fit also affects ease of use. A snug clamp installs smoothly. It holds firm under pressure. High pressure pipe repair clamps need exact sizing. This ensures they handle stress. Double-check measurements to avoid errors. The right size guarantees success.

Durability and Resistance to Environmental Conditions

Durability matters when picking a pipe repair clamp. The material must resist wear. It should handle rust, heat, and chemicals. Stainless steel excels here. It fights corrosion in wet or harsh settings. This makes it ideal for long-term use.

Environmental factors test clamps. Temperature swings can weaken some materials. Chemical exposure can erode others. Choose clamps built for your conditions. A durable repair clamp pipe saves money over time. It reduces the need for frequent replacements.

Step-by-Step Guide to Using a Pipe Repair Clamp

Preparing the Damaged Area for Repair

Before fitting a pipe repair clamp, prep the damaged spot. Stop the flow of water or fluid. This prevents leaks during repair. Clean the area well. Remove dirt, rust, or debris. These can block a tight seal. Use a wire brush or sandpaper. Smooth out rough edges.

Ensure the surface is dry. Moisture weakens the rubber gasket’s grip. A clean, dry pipe ensures the clamp works right. Proper prep sets up a strong repair. It makes the next steps easier.

Installing the Clamp Properly

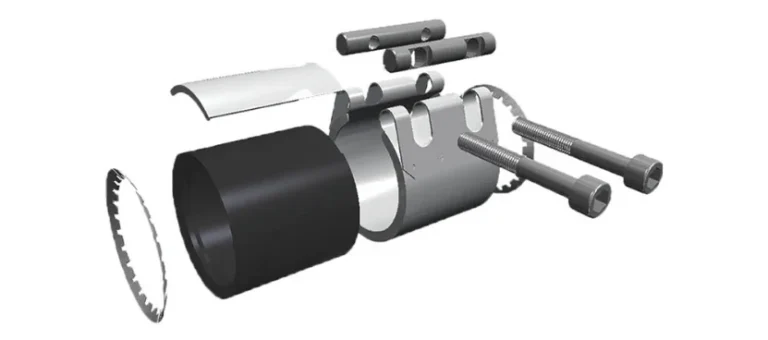

Pick a pipe repair clamp that fits your pipe’s size and material. Open the clamp. Place it over the damaged area. Align the rubber gasket with the leak. Tighten the bolts evenly. Use a wrench or screwdriver. Apply steady pressure for a firm seal.

Don’t overtighten. This can harm the clamp or pipe. Check alignment of all parts. Misplaced clamps may fail. A well-installed repair clamp pipe holds tight. It restores the pipe’s function quickly.

Testing the Repaired Section for Leaks

After fitting the clamp, slowly restart the fluid flow. Watch for leaks around the repair. If leaks persist, adjust the clamp. Retighten as needed. For high pressure pipe repair clamps, run a pressure test. This confirms the fix holds under load.

Testing ensures the repair is solid. It prevents future issues. A leak-free clamp means success. Regular checks after installation keep the system reliable.

Advantages of Using a Pipe Repair Clamp

Quick and Efficient Solution for Leaks

Pipe repair clamps fix leaks fast. They don’t need major pipe dismantling. This cuts downtime. It protects nearby structures. A repair clamp pipe seals issues in minutes. This efficiency is vital in emergencies. It keeps systems running with minimal delay.

Their speed saves resources. No need for long shutdowns. They stop leaks before damage spreads. This makes them a practical choice for any pipeline.

Cost-Effectiveness Compared to Replacement

Replacing pipes costs a lot. It takes time and labor. Pipe repair clamps are cheaper. They target specific damage. This avoids full pipe replacement. They also reduce waste. This makes them eco-friendly.

A repair clamp pipe saves on materials too. It extends pipe life without big expenses. For businesses or homes, this affordability is a major win.

Versatility Across Various Pipe Types

Pipe repair clamps work on many pipe types. They handle metal, plastic, or composite materials. This flexibility suits countless uses. From home plumbing to industrial systems, they adapt. High pressure pipe repair clamps manage tough conditions. They ensure broad compatibility.

Their range makes them valuable. No matter the pipe, a clamp can help. This versatility simplifies repair planning. It covers diverse needs with one tool.

Maintenance and Care for Long-Term Use of Clamps

Regular Inspection of Installed Clamps

Check installed pipe repair clamps often. Look for wear or rust. Loose bolts can weaken seals. Damaged gaskets may leak. Spotting issues early prevents failures. Regular checks keep the repair clamp pipe working well.

Inspections are simple but vital. They ensure long-term reliability. A quick look can save big repairs later. Stay proactive to maintain performance.

Tips for Ensuring Longevity and Performance

Store extra clamps in a dry place. Keep them away from corrosive substances. This preserves their condition. Follow maker’s rules when installing. Use the right torque for bolts. Match clamps to pipe materials.

Proper care extends clamp life. A well-kept repair clamp pipe performs better. It stays ready for future fixes. These steps ensure lasting value.

Конфлексы суставы is an expert manufacture of various types of industrial pipelineconnection and repair products for more than 15 years, It will make you feel more than you paid for.

Часто задаваемые вопросы

How do I pick the right pipe repair clamp?

Choose based on pipe material and size. This ensures a good fit and function.

Are pipe repair clamps reusable?

Most are for one-time use. Some high-quality ones may work again if undamaged.

Can pipe repair clamps handle high-pressure systems?

Yes. Double-band or high pressure pipe repair clamps are built for tough systems.

Do I need a pro to install a pipe repair clamp?

Basic fixes can be DIY. For complex or critical pipes, get expert help.

For more on pipeline repair tools trusted globally in water, heating, gas, and oil sectors, contact Конфлексы суставы today!