Understanding Flange Leak Repair Clamps

What Are Flange Leak Repair Clamps?

Flange leak repair clamps are handy gadgets built to fix leaks in flange gaskets. They dish out a quick sharp way to plug leaks without tearing apart the whole pipe setup. You’ll spot ‘em in trades like oil and gas chemical processing and water treatment where keeping pipes tight is a big deal. They wrap a solid seal ‘round the flange stop more drips and keep the pipeline humming safe.

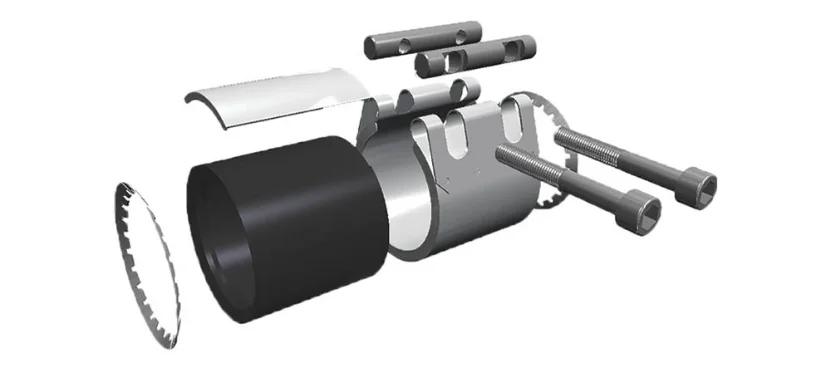

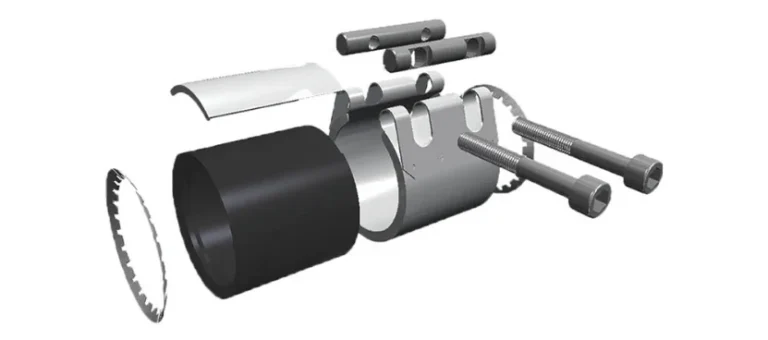

Key Components of Flange Leak Repair Clamps

The magic of flange leak repair clamps comes from their build and bits. They’ve got a tough outer shell usually whipped up from sturdy stuff like stainless steel or carbon steel. That shell’s made to take big pressure and shrug off rust so it holds up in rough spots.

Inside there’s a sealing piece often rubbery stuff that locks in a snug fit ‘round the flange. This bit’s key it stops leaks and handles little flaws on the flange face. Plus most clamps have bolts or clips you can tweak for a tight grip that fits just right.

Types of Flange Leak Repair Clamps

Flange leak repair clamps come in all sorts to match different jobs and needs. Here’s the lineup:

- Standard Flange Repair Clamps:Good for everyday fixes fit a bunch of flange sizes.

- Split-Type Clamps:Perfect where space is tight or you can’t yank the pipe apart.

- High-Pressure Clamps:Built tough for wild pressure gigs like oil and gas hotshots.

- Customizable Clamps:Some outfits like Conflex Customization Service tweak ‘em to your exact specs.

Causes of Gasket Leaks in Flanges

Common Reasons for Gasket Failures

Gasket flops are a top trigger for leaks in flanges. One big culprit’s wear gaskets break down over time from heat chemicals or pressure swings. Cheap gasket stuff can lose its bounce or turn brittle messing up how they seal.

Picking the wrong gasket for the job sets ‘em up to fail too. If it can’t hack the heat or tough chemicals it’ll give out quick.

Environmental Factors Contributing to Leaks

Outside stuff plays a hefty role in sparking gasket leaks. Rust is a major player moisture saltwater or harsh chemicals chew up gaskets and flange faces opening leak paths.

Heat shifts mess things up too. Hot-to-cold stretches and squeezes put gaskets under strain especially if they’re not built for it. Over time that tension cracks or warps ‘em.

Vibes from gear or outside jolts can loosen flange hookups too busting the gasket’s seal.

The Role of Improper Installation

Sloppy setup’s another leak starter in flanges. If gaskets don’t line up right when you bolt ‘em in they won’t seal even ‘cross the flange. That leaves weak spots ripe for leaks when pressure hits.

Over-cranking or skimping on bolts tweaks gasket work too. Too much squeeze can smash or twist the gasket. Too little and it won’t seal worth a darn.

To dodge this stick to tight setup rules and grab the right gear for flange jobs.

How Flange Leak Repair Clamps Work to Stop Gasket Leaks

Mechanism Behind Leak Sealing

Flange leak repair clamps kick leaks by locking a firm snug seal ‘round the flange. They’re rigged to tackle gasket flops like bumpy faces or worn-out stuff. The trick’s in tough materials and slick parts working together to press even on the flange. That squeeze makes the seal inside hug any rough patches shutting leaks down.

The sealing bit usually stretchy rubber is the star here. It bends but holds tough fits small dents and keeps a solid block. Bolts or clips you can adjust let you dial in the fit just right without stressing the gasket too hard.

Materials Used in Effective Clamp Design

What flange leak repair clamps are made of shapes how well they roll and how long they last. The outer shell’s often high-power metals like stainless steel or carbon steel. These picks handle big pressure and laugh off rust fit for nasty work zones.

The sealing piece leans on rubbery mixes like EPDM or NBR. They stand up to chemicals heat swings and rough knocks. Pairing a burly shell with a trusty seal keeps the clamp humming in all kinds of setups.

Advantages of Using Pipe Repair Clamps for Gasket Leaks

Pipe repair clamps bring heaps of wins for tackling gasket leaks in flanges. A top perk they fix leaks without yanking the whole pipe system apart. That saves time and cuts downtime in big-deal jobs.

They’re handy too work from chill water lines to roaring oil and gas pipes. That flex makes ‘em gold in trades where pipe trust is king.

They’re easy on the wallet next to old-school fixes like swapping whole pipe chunks or flanges. Plus they’re a cinch to slap on trims labor tabs and keeps upkeep simple.

Choosing the Right Pipe Repair Clamp for Your Needs

Factors to Consider When Selecting a Clamp

Picking the right pipe repair clamp takes some thinking to nail performance and fit your gig. Key stuff to weigh:

- Operating Pressure:Make sure the clamp’s rated for your pipe’s push.

- Temperature Range:Grab one with stuff that can take your heat or cold.

- Chemical Compatibility:Check the shell and seal can shrug off your system’s brews.

- Flange Size:Get dead-on measures for a clamp that hugs tight.

Eyeing these bits lands you a clamp that fits your needs and holds up strong.

Sizing Options for Different Pipe Dimensions

Pipe repair clamps come in all sizes to match pipe widths and flange setups. Makers dish standard fits for usual pipe runs but custom cuts are out there for oddball jobs.

Measure your flange sharp before you buy. That’s diameter thickness and extras like bolt lines or raised bits that might tweak off-the-rack fits.

Recommendations for Emergency Repairs

When leaks hit hard and you need a fix fast pipe repair clamps are clutch. They slap on quick let you plug leaks without killing ops too long. In trades like oil and gas or chemical processing where tiny drips can spiral big keeping clamps handy is a must.

Sinking cash in top-tier clamps built for crash fixes gets you ready for surprise flops while keeping risks low from pipe busts.

Frequently Asked Questions (FAQs)

What is a pipe repair clamp?

It’s a gadget to seal leaks or patch pipe damage by locking tight ‘round the spot without big fix jobs.

How do I choose an appropriate flange leak repair clamp?

Look at pressure heat range chemical fit and dead-on flange measures when picking one.

Are pipe repair clamps suitable for high-pressure systems?

Yup some types are rigged to handle big pressure gigs while sealing tight.

What materials are commonly used in flange leak repair clamps?

Tough metals like stainless steel or carbon steel make the shell. Rubbery stuff like EPDM or NBR does the sealing thanks to grit and resistance.

Can pipe repair clamps be used for emergency repairs?

Sure they’re ace for quick fixes slap on fast and plug leaks without big downtime.

Folks hunting slick pipe fixes can check out gear from outfits like Conflex cooking up fresh designs for all kinds of trade jobs ‘round the globe.