Understanding the Functionality of Repair Clamps

What is a Pipe Repair Clamp?

A pipe repair clamp is a flexible and powerful device employed to mend leaks or harm in pipelines without requiring major system halts or pipe swaps. These clamps aim to deliver a swift and dependable fix by enclosing the damaged spot, restoring the pipeline’s strength, and keeping interruptions to a minimum. They find frequent use across multiple sectors, such as water distribution, oil and gas, chemical industries, and beyond.

Common Applications of Repair Clamps in High-Pressure Systems

Repair clamps are vital in high-pressure setups where leaks or impairments could trigger serious operational troubles or safety risks. These tools often come into play when urgent fixes are needed to avoid downtime or ecological harm. For example, they seal cracks or holes in high-pressure water lines effectively. Likewise, in oil and gas networks, repair clamps offer a short-term but sturdy remedy for pipeline issues stemming from rust, physical strain, or outside forces.

Key Features of High-Pressure Repair Clamps

Material Selection for Strength and Durability

The substances chosen for high-pressure repair clamps greatly influence their effectiveness and lifespan. Typical options include stainless steel and carbon steel, valued for their strong balance of power and weight, plus resistance to rust. Stainless steel stands out for its toughness and capacity to endure tough surroundings, making it perfect for marine or chemical uses. Carbon steel, meanwhile, provides a budget-friendly choice while retaining enough durability for many industrial purposes.

The Role of Gasket Design in Ensuring Effective Sealing

The gasket’s structure in a repair clamp is essential for creating a tight seal around the injured pipe section. These gaskets usually consist of elastomers like EPDM (ethylene propylene diene monomer) or NBR (nitrile butadiene rubber), which excel at sealing under diverse pressure and heat levels. A smartly crafted gasket stops leaks and adjusts to small flaws on the pipe’s surface. This ensures a firm hold.

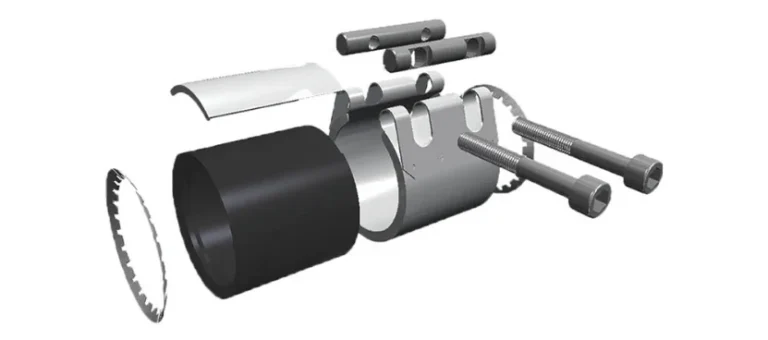

Structural Design for Handling Higher Pressures

High-pressure repair clamps are built with solid frameworks to cope with the intense forces of raised pressures. Elements like strengthened bands, multi-bolt setups, and precise crafting boost their ability to manage extreme settings. What’s more, these clamps often feature advanced locking systems. These enhance steadiness and stop shifting during use.

Types of Repair Clamps for High-Pressure Situations

Overview of Full Circle® Repair Clamps

Full Circle® repair clamps rank among the top-known options for pipeline fixes. They boast a complete circular build that spreads pressure evenly around the pipe. This guarantees a tight seal, even in high-pressure states. Available in diverse sizes and styles, they suit various pipe widths and materials. Their adaptability makes them great for tackling leaks from rust, punctures, or joint breakdowns.

Differences Between Carbon Steel and Stainless Steel Clamps

When picking between carbon steel and stainless steel repair clamps, several aspects matter:

- Corrosion Resistance:Stainless steel clamps outshine carbon steel in fighting rust. This makes them excellent for tasks involving harsh substances or settings.

- Cost:Carbon steel clamps usually cost less than stainless steel ones while still performing well in milder conditions.

- Strength:Both materials show great power. However, stainless steel excels under extreme heat or pressure.

- Application Suitability:Choosing between them hinges on the job’s specific needs, like environmental factors and budget limits.

Repair clamps are crucial tools for upholding pipeline strength across industries. They enable fast, trustworthy repairs, cutting downtime while boosting safety and efficiency.

Industry Standards and Recommendations for Repair Clamp Design

Insights from ASME PCC-2 Guidelines on Pressure Equipment Repairs

The ASME PCC-2 guidelines offer a detailed blueprint for repairing pressure equipment, including pipelines. They stress the need for repair clamps that meet strict quality and safety rules to preserve the fixed system’s wholeness. The guidelines suggest designing clamps to endure the pipeline’s exact working conditions, such as pressure, temperature, and surroundings. This ensures a dependable seal and steady structure.

A major point in ASME PCC-2 is the call for deep engineering reviews during design. This involves stress checks and material picks to confirm the clamp can handle steady and shifting loads well. Plus, the guidelines push for routine checks and upkeep of repair clamps. This extends their use and prevents possible breakdowns.

Engineering Calculations and Design Methods for Split-Sleeve Clamps

Split-sleeve clamps are popular for pipeline repairs due to their flexibility and simple setup. Designing them requires careful math to ensure they fit various pipe sizes and thicknesses. Engineers factor in hoop stress, axial force, and bending moments to fine-tune performance across conditions.

Advanced finite element analysis (FEA) tools often simulate how split-sleeve clamps act in high-pressure cases. This spots weak areas in the design. Engineers can tweak things before making them. Also, today’s split-sleeve clamps include adjustable bolts and reinforced bands. These boost their fit and sealing power.

Innovations and Advancements in Repair Clamp Technology

Enhancements in Gasket Materials for Better Sealing Efficiency

Gaskets are key to a repair clamp’s success by securing a tight seal around damaged pipe parts. Recent strides in gasket materials have greatly lifted their performance, especially in high-pressure uses. Elastomers like EPDM and NBR remain top picks for their strong resistance to heat, chemicals, and wear.

New gasket designs now use layered builds that improve sealing, even when pressure shifts. For example, some blend soft elastomer layers for flexibility with tougher materials for longevity. These upgrades cut leaks and lengthen repair clamp life by easing wear on vital parts.

The Role of Research and Development in Improving Product Adaptability

Research and development (R&D) efforts have fueled breakthroughs in the repair clamp field. By using cutting-edge tools like 3D printing and advanced metalwork, makers craft custom fixes for specific pipeline needs. This tailoring ensures repair clamps work across uses, from water systems to oil plants.

Plus, R&D tackles user hurdles, like setup ease and pipe material fit. Modern clamps now sport handy features like quick-release parts and modular designs that speed up assembly. These changes save time and trim labor costs for pipeline fixes.

The company, Conflex, crafts various pipeline joints and boasts a skilled R&D team, renowned globally in the pipeline world. To meet market needs, we prioritize customer wants, gather wide market insights, and keep refining product designs. We also develop fresh products to boost adaptability and use range.

Frequently Asked Questions

What types of damages can repair clamps fix?

Repair clamps can handle cracks, pinholes, punctures, joint failures, and other small-scale pipe damages.

Are repair clamps suitable for permanent fixes?

Though mainly built for short-term use, some top-tier repair clamps can work as lasting solutions, based on the job.

How do I choose between carbon steel and stainless steel clamps?

Weigh needs like rust resistance, setting conditions, budget limits, and pressure levels when deciding.

Can repair clamps be used on all types of pipes?

Yes, repair clamps come in many sizes and setups to fit different pipe materials, like metal or plastic.

What industries commonly use repair clamps?

Sectors like water management, oil and gas production, chemical plants, and power generation often rely on repair clamps.

For more details about our offerings or services tailored to your needs: Conflex produces various pipeline joints and has a skilled R&D team focused on customer needs. We keep enhancing product adaptability through innovative work.